- Gaea

- 中国

- 5-25天

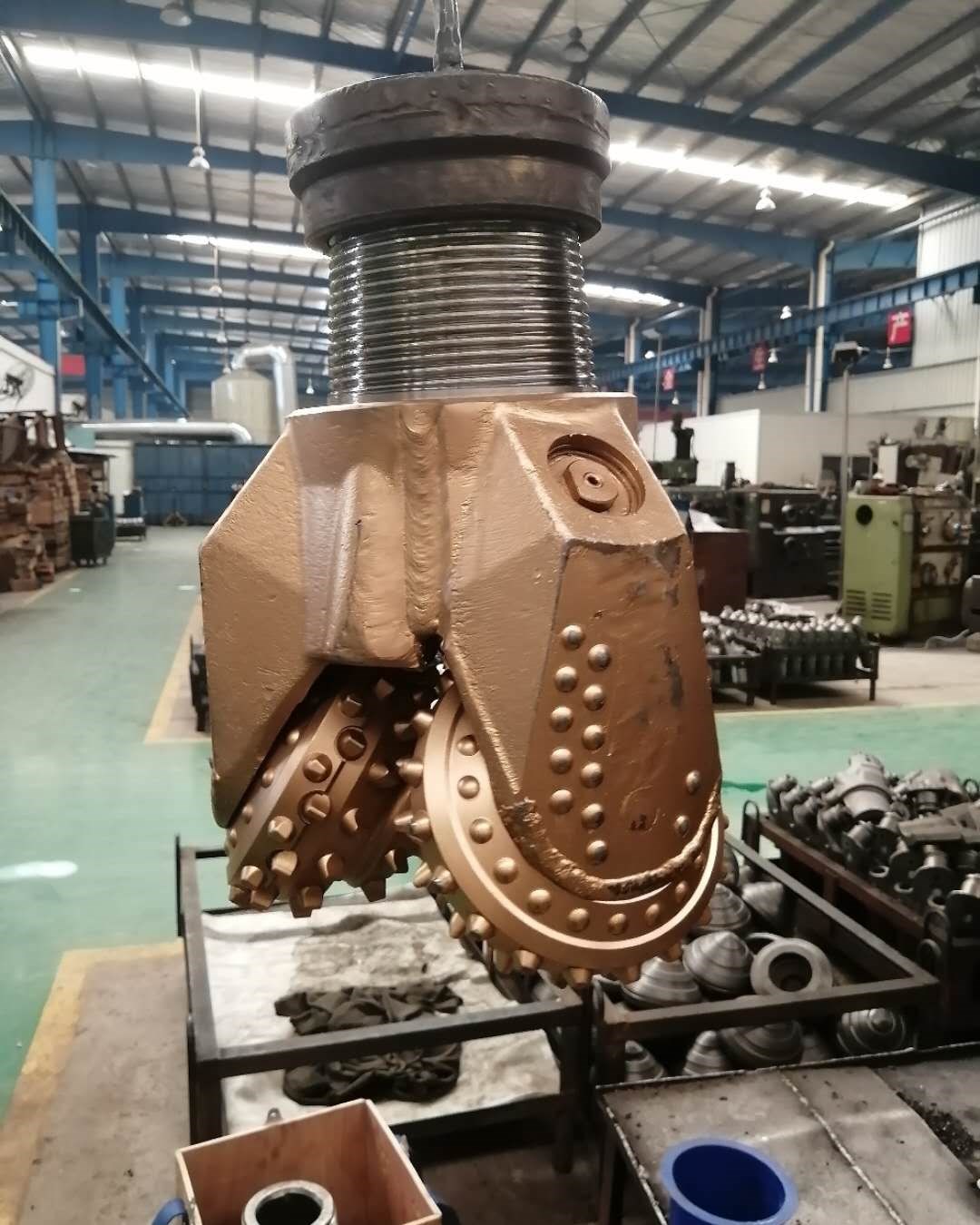

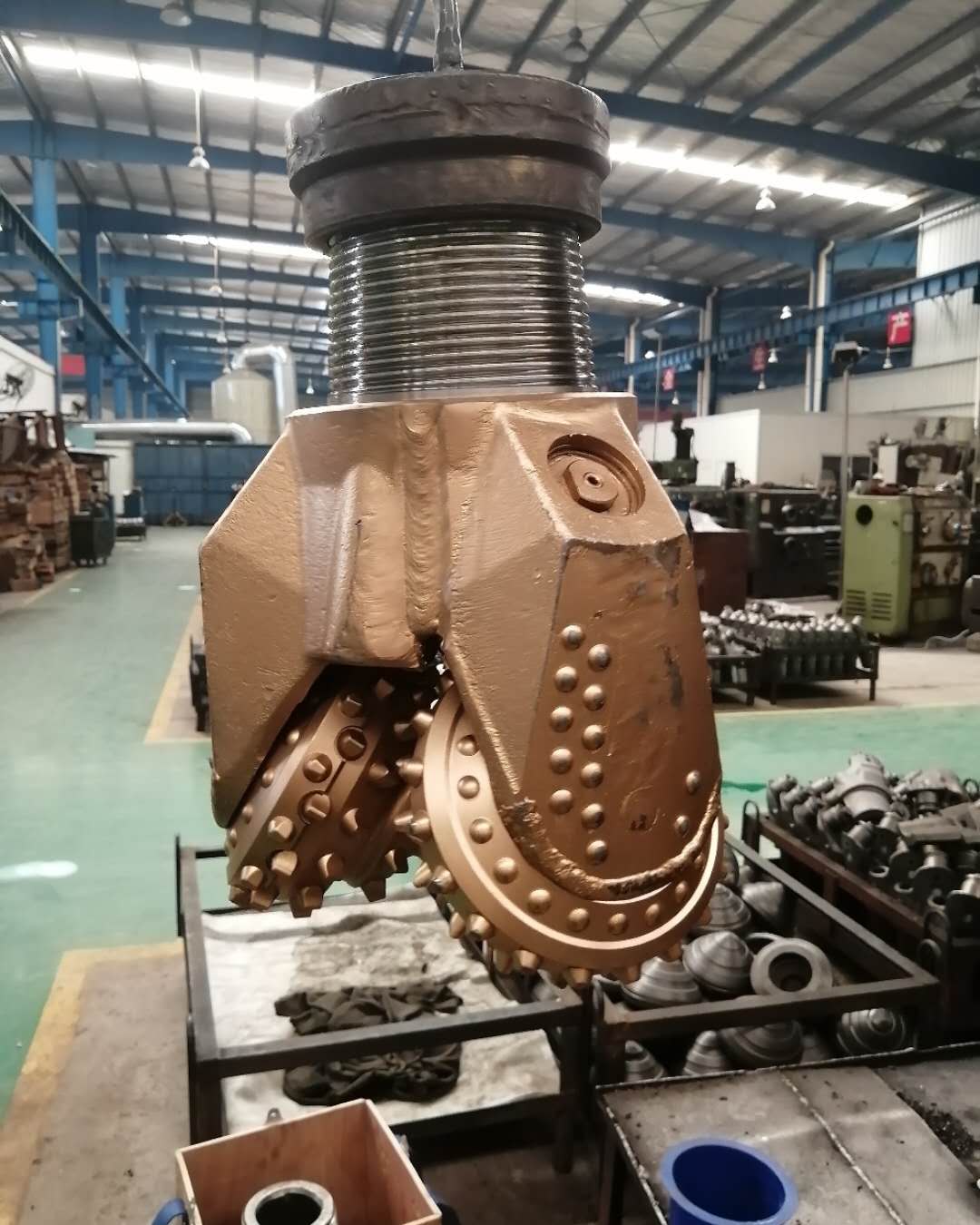

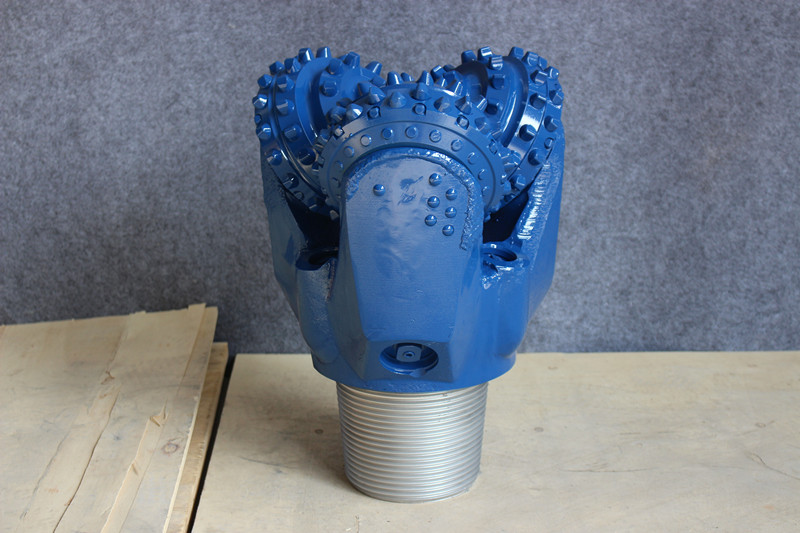

Experience exceptional drilling performance with our Tricone Roller Bits. Engineered with a cutting-edge design, including maximum cone offset and a strategic cutting structure, our Tricone Roller Bits deliver high bit penetration rates. The deep intermesh of cutter rows effectively prevents bit bailing, even in sticky formations. Trust in the reliability and efficiency of our Tricone Roller Bits for superior drilling results. Choose our Tricone Roller Bits and achieve unmatched productivity in your drilling operations.

Tricone Roller Bits 10.5-14inch

Related Reports:

Introduce information about tricone bits;

Key operating points of roller cone bits;

Why does the drill bit of the rotary excavator get stuck during drilling?

Introducing our high-performance Tricone Drill Bits, specifically designed for water well drilling, oilfield drilling, and challenging hard rock formations. With diameters ranging from 10.5 to 14 inches, our Tricone Drill Bits deliver exceptional results in a variety of drilling applications.

In water well drilling, our Tricone Drill Bits demonstrate superior efficiency and reliability. Equipped with advanced cutting structures and optimized bearing designs, they effortlessly penetrate various formations, including hard rock, sandstone, and limestone. Count on our Tricone Drill Bits to ensure smooth drilling operations and increased productivity in water well projects.

For oilfield drilling, our Tricone Drill Bits excel in their ability to handle the demands of complex drilling environments. With their durable construction and specialized cutting structures, they deliver consistent and reliable performance, even in challenging formations. Experience reduced drilling time and enhanced productivity with our Tricone Drill Bits in oilfield operations.

When it comes to hard rock drilling, our Tricone Drill Bits are specifically designed to tackle the toughest formations. Featuring rugged construction and precision-engineered cutting elements, they deliver exceptional penetration rates and extended bit life. Trust in our Tricone Drill Bits to maximize drilling efficiency and achieve outstanding results in hard rock applications.

At Liaoning Gaea, we take pride in being a trusted supplier of high-quality Tricone Drill Bits. Our expertise and commitment to excellence ensure that our products meet the highest industry standards. Choose our Tricone Drill Bits for water well drilling, oilfield drilling, and hard rock applications, and experience the difference of superior performance and reliability.

Contact us today to learn more about our comprehensive range of Tricone Drill Bits and how they can optimize your drilling operations in water well drilling, oilfield drilling, and hard rock applications.

Normal IADC:

437Soft Formation TCI Tricone Bits:

The 437 TCI bits are used to drill low compressive strength, very soft formations. TCI bits maximize the use of both conical and chisel tungsten carbide inserts of large diameters and high projection. This cutting structure design, combined with maximum cone offset, results in high bit penetration rates. The deep intermesh of cutter rows prevents bit bailing in sticky formations.

517Medium Formation TCI Tricone Bits:

The 517 features aggressive chisel tungsten carbide inserts on the heel rows and inner rows. This design provides a fast drilling rate and added cutting structure durability in medium-to-medium hard formation. The HSN rubber O-ring provides adequate sealing for bearing durability.

637Hard Formation TCI Tricone Bits:

The 637 bits can be used to drill hard and abrasive formation. Wear-resistant tungsten carbide inserts are used in the outer rows to prevent loss of bit gauge. Maximum numbers of hemispherical-shaped inserts are used in all rows to provide cutter durability and long life.

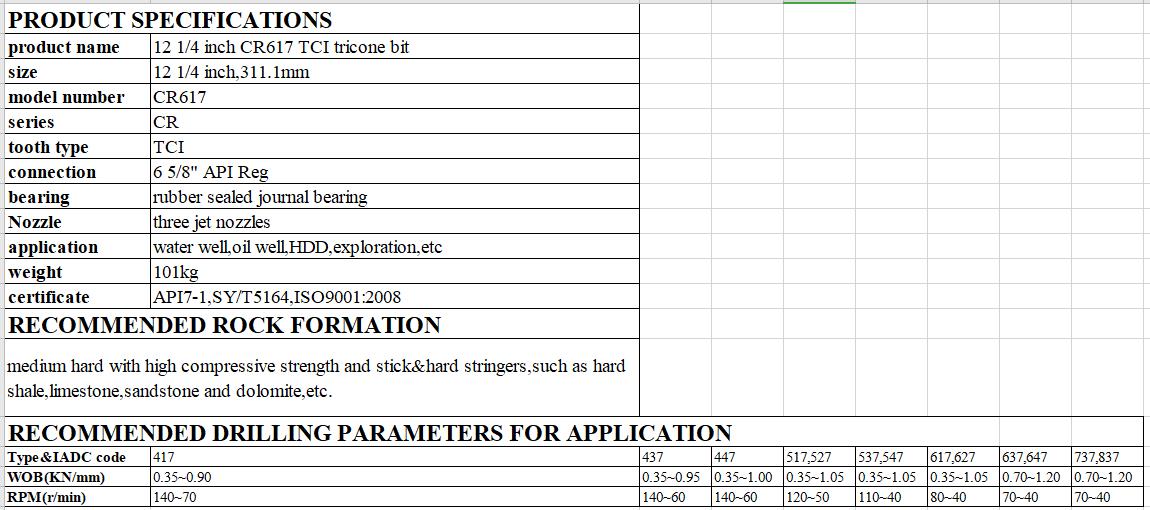

617Medium-Hard Formation TCI Tricone Bits:

The 617 features robust chisel tungsten carbide inserts on the heel row and conical on the inner rows. This design provides a fast drilling rate and added cutting structure durability in medium to medium hard formations. The HSN rubber O-ring provides adequate sealing for bearing durability.

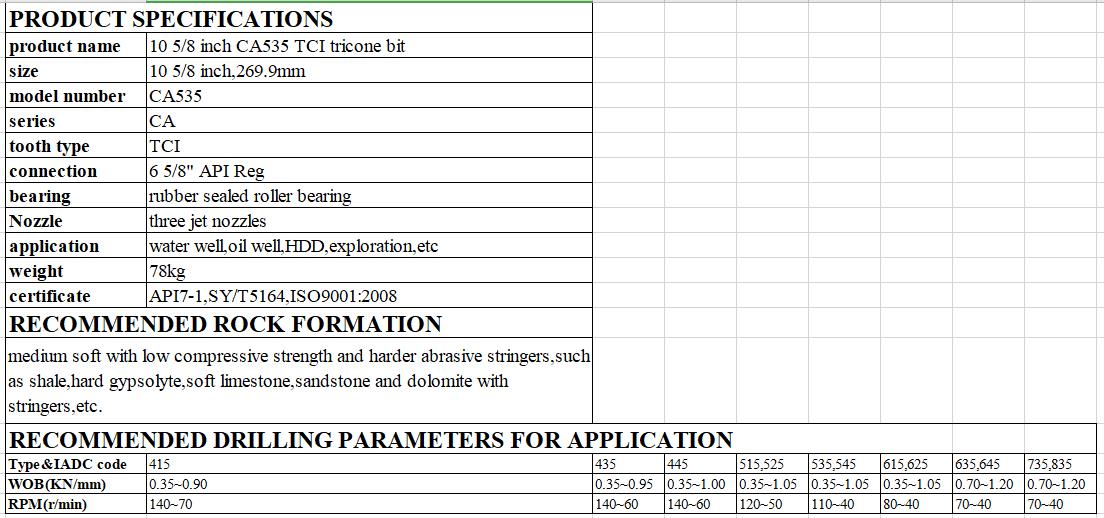

10 5/8Inch IADC535:

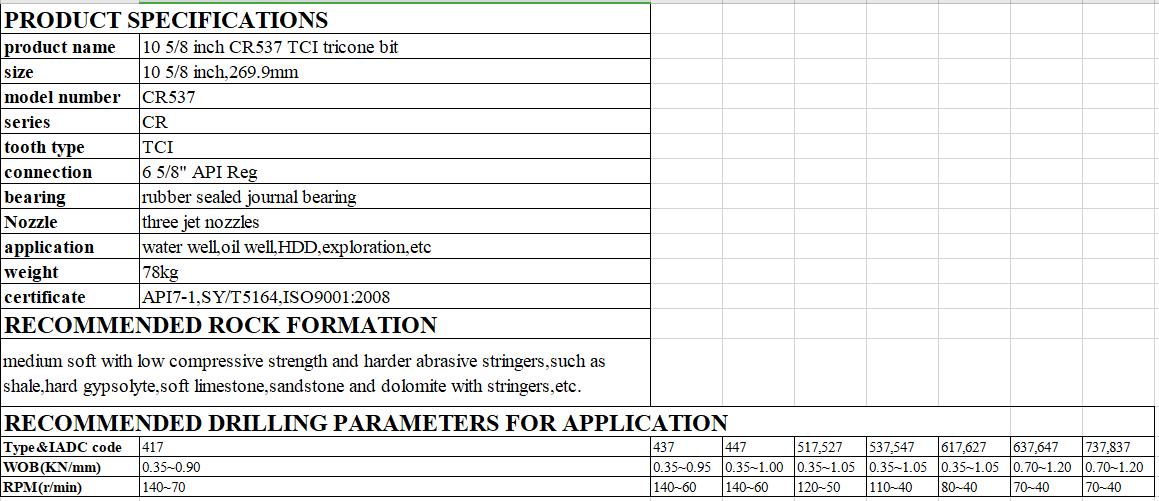

10 5/8Inch IADC537:

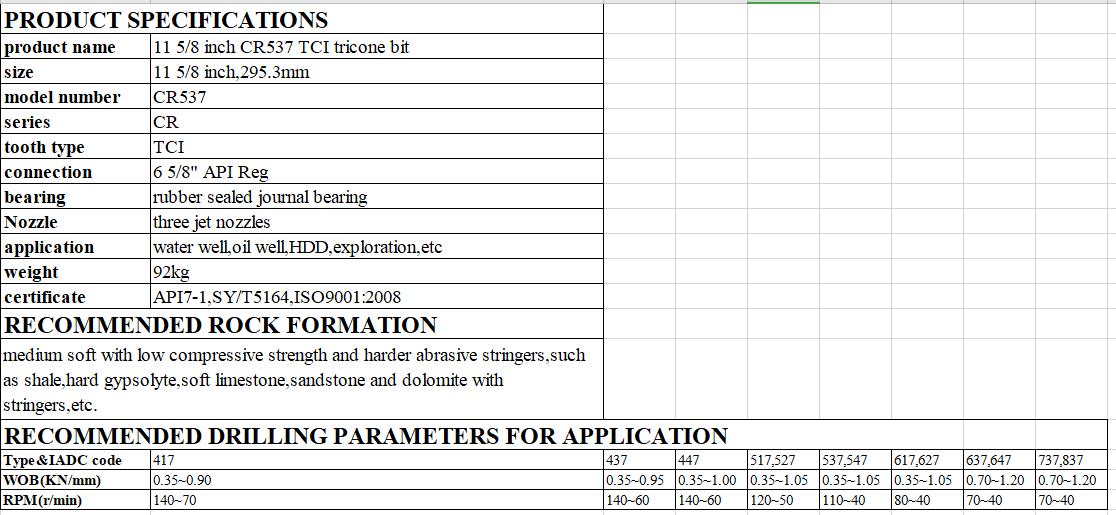

11 5/8Inch IADC537:

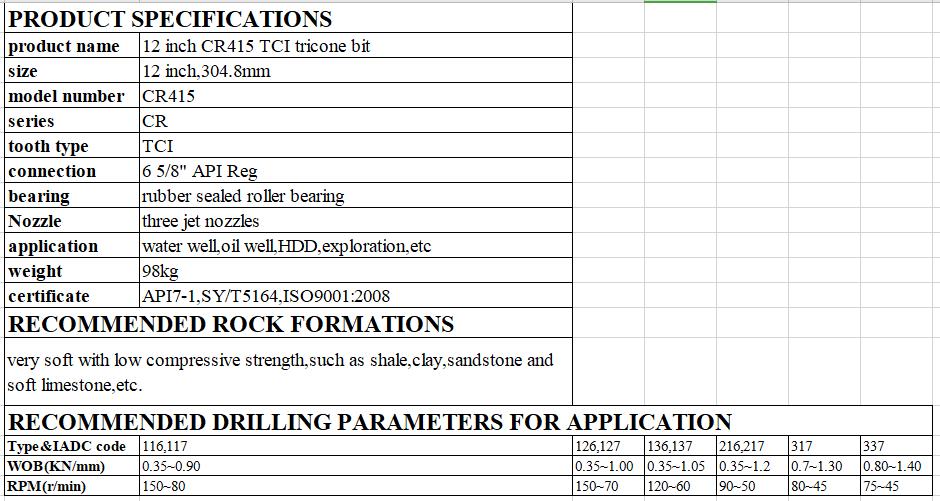

12 Inch IADC615:

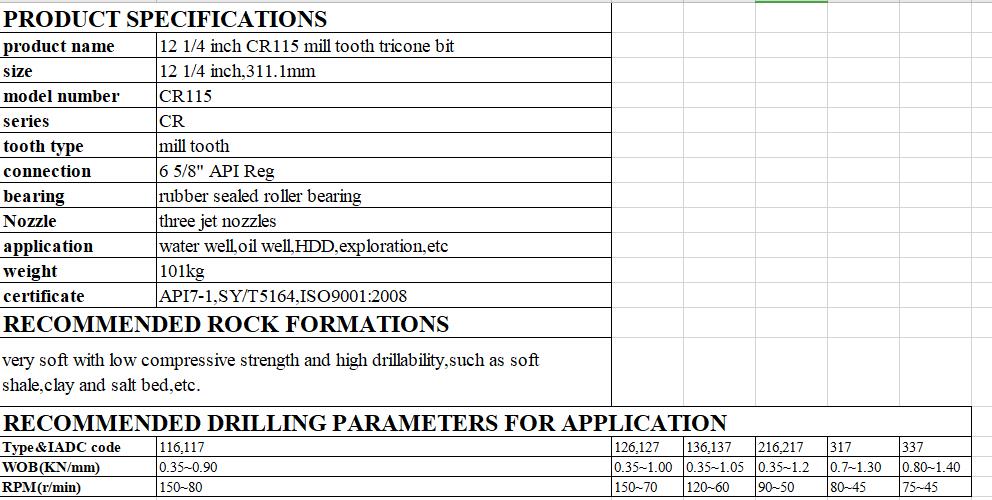

12 1/4Inch IADC115:

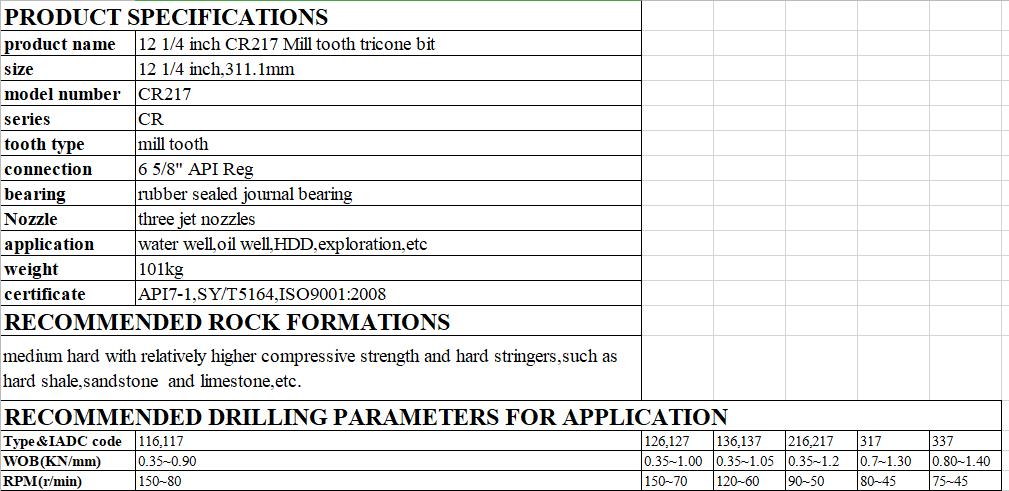

12 1/4Inch IADC217:

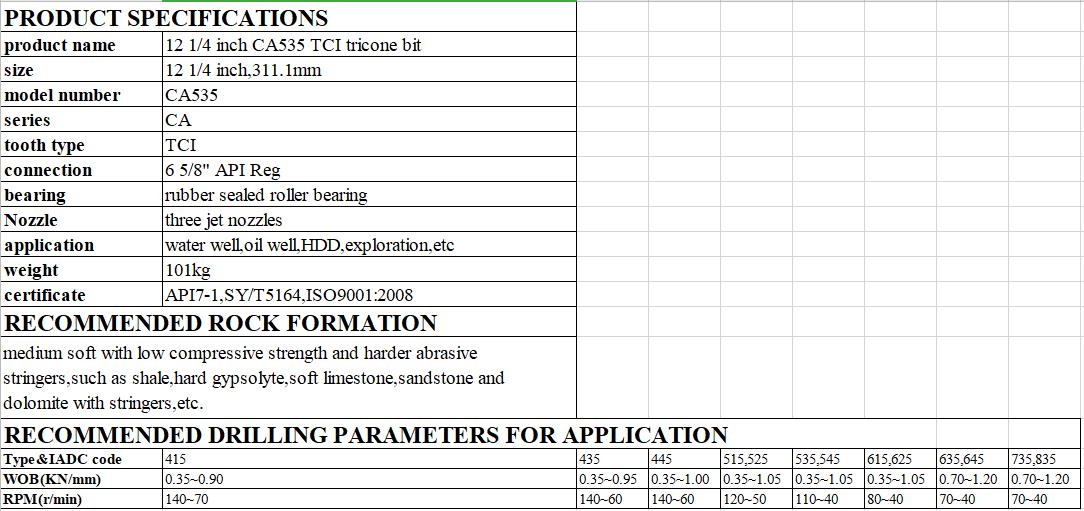

12 1/4Inch IADC535:

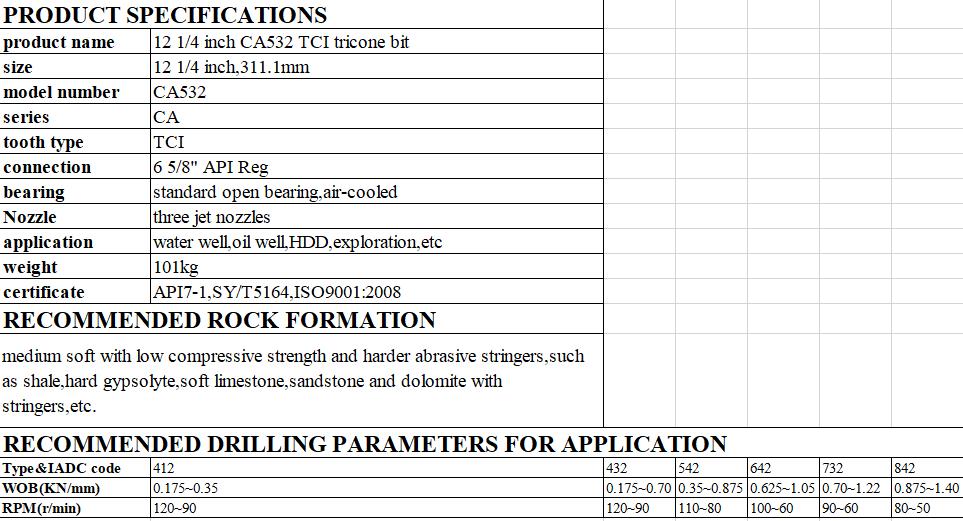

12 1/4Inch IADC532:

12 1/4Inch IADC617:

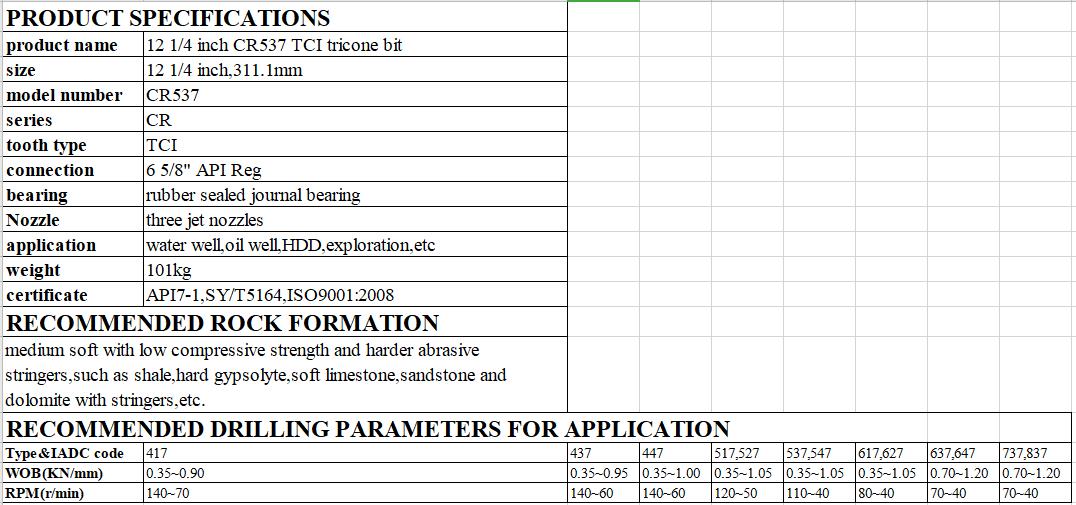

12 1/4Inch IADC537:

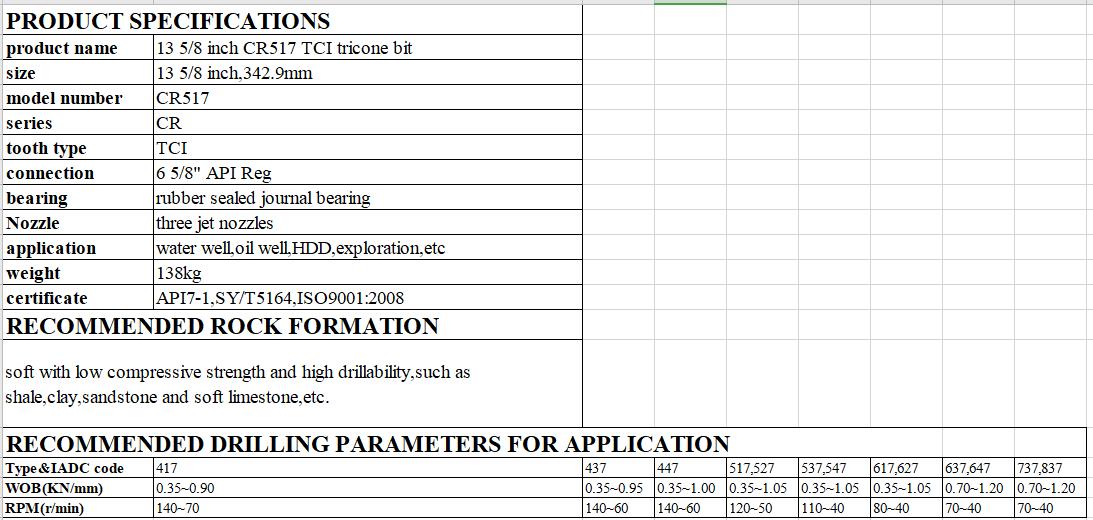

13 5/8Inch IADC517: