- Gaea

- 中国

- 5-25天

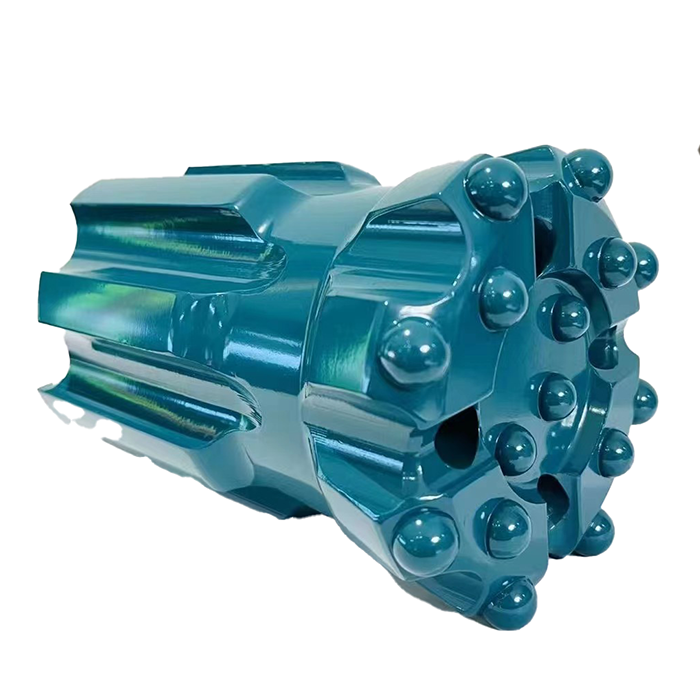

The T51 threaded drill bit is a specially designed drill bit suitable for rock drilling operations with high hardness and severe wear under high air pressure. This bit has excellent penetration rates and high strength steel-resistant floating properties, making it ideal for optimizing digging efficiency. Our T51 thread drill bits are manufactured with high-quality materials, which ensures its long life and excellent performance. In addition, our factory has advanced production equipment and strict quality control, so that our products have been widely recognized and trusted in exporting to Europe, America and Southeast Asia. If you are looking for a solution to increase efficiency in challenging mining environments, the T51 threaded drill bit will be your best choice.

T51 Thread Button Bits T51-115

Related Reports:

Instructions for using the drill bit;

Application of drilling bits Carbide Ball Teeth;

What processing problems do you need to know about open-ended drills;

T51 Threaded Drill bits Introduction

T51 threaded button drill bit is a high-quality, high-efficiency mining drilling tool, which is one of the core products of our company.

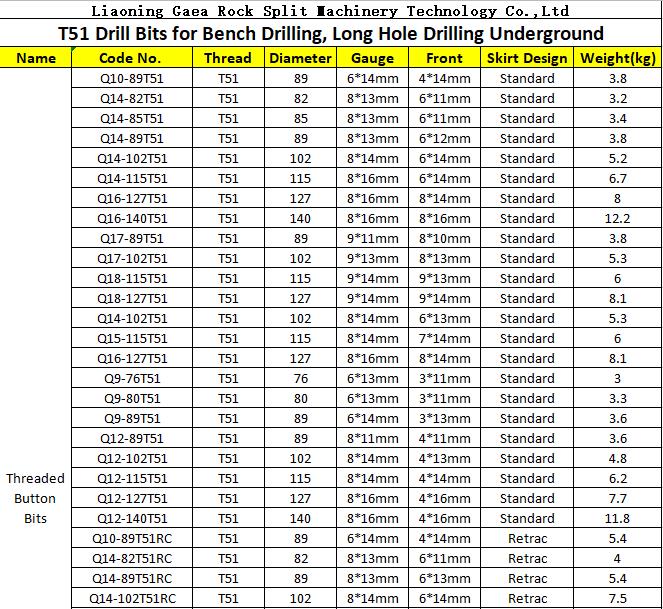

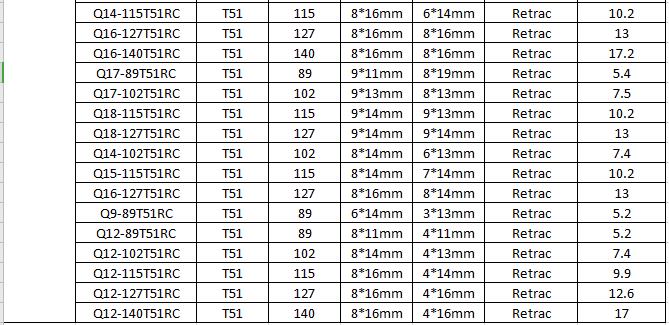

Liaoning Gaea T51 threaded button drill bit is made of high-strength steel and adopts special heat treatment technology to ensure its excellent wear resistance and long life. In addition, the thread type of our T51 threaded button drill bit is T51, and the main diameter is 89/102/115/127mm, which can meet the needs of different mining sites. Whether in hard or soft rock formations, our T51 threaded drill bits drill with ease and maintain excellent performance.

Plus, our T51 threaded button bits feature an easy-change feature, which means worn bits can be easily replaced without having to replace the entire drill. In this way, our customers save costs and increase drilling efficiency.

In the end, I want to emphasize that our company has its own factory and export experience, which can ensure that the price and quality of the products have advantages. We have won a good reputation and word of mouth in the markets of many countries such as Europe, America and Southeast Asia. If you are looking for high-quality, high-efficiency, easy-to-replace T51 threaded button drill bits, our product will be your best choice.

Key Specifications/Special Features:

Bit face shape selection:

1. Drop Center Bit

For high penetration rates in soft to medium hard and fissured rock formations. Low to medium air pressures. Maximum hole deviation control.

2. Concave Face

The all-round application bit face specifically for medium hard and homogenerous rock formations. Good hole deviation control and good flushing capacity.

3. Convex Face

For high penetration rates in soft to medium-hard with low to medium air pressures. It is the most resistance to steel wash, and may reduce the load and wear on the gauge buttons, but poor hole deviation control.

4. Double Gauge Face

This kind of face shape is suitable for fast penetration rates in medium to hard rock formations. Designed for high air pressures and good resistance to steel wash step gauge bit.

5. Flat Face Bit

This kind of face shape is suitable for hard to very hard and abrasive rock formations in applications with high air pressures. Good penetration rates an resistance to steel wash.

Carbide button shape selection:

1. Domed/Round Button

2. Parabolic/Semi-Ballistic Buttons

3. Ballistic Button

4. Sharp Button

5. Flat Button

Feature:

· Code No.: Q14-115-T51

· Thread: T51

· Diameter: 115mm

· Gauge Buttons: 8

· Front Buttons: 6

· Carbide Design: Dome

· Face Design: Flat

· Skirt Deign: Standard

Diameter: 76mm, 89mm, 102mm

Skirt body: retrac, and normal, straightrac

Face type: flat, uniface, Drop Center

Carbide shape: Dome, ballistic, semi-ballistic

Used in bench drilling, underground long hole drilling to match extension MF rod, MM rod heavy duty top hammer drilling tools.

Drop Center Face T51 Threaded Button Bit

Dome Button T51 Threaded Button BitT51 Threaded Drill Bit T51 Threaded Drill Bit

14 Dome carbide inserts T51 threaded drill bit with drop center face design, 89 mm diameter match with extension drill steels. Drop center bits (DC) are well suited for drilling straighter holes in less abrasive and less consolidated rock at a faster rate.