- Gaea

- China

- 10000pcs/month

Gaea "retrac Threaded Button Bits T51 115mm: The epitome of drilling precision and power. Unleash efficiency in rock drilling with this versatile tool."

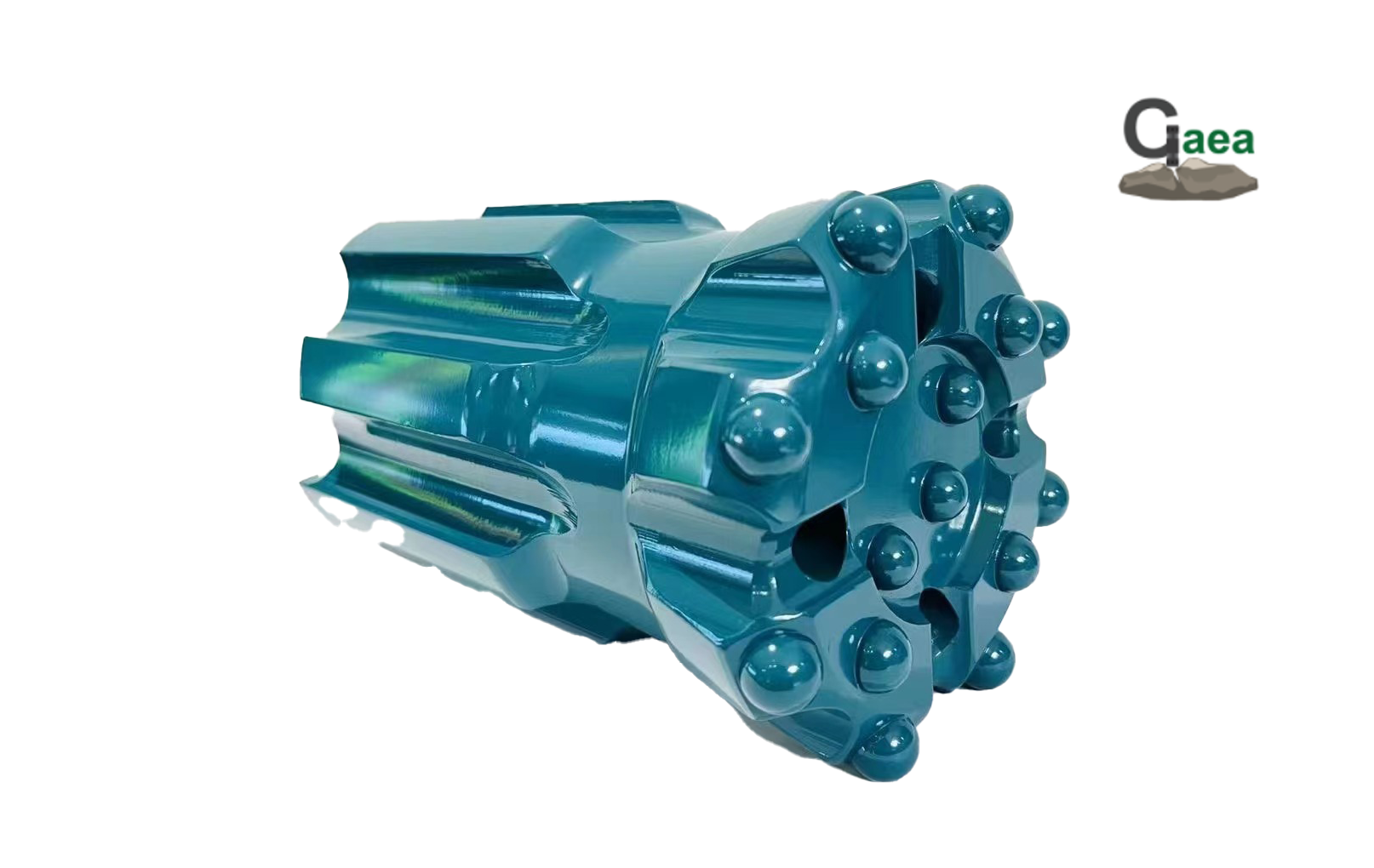

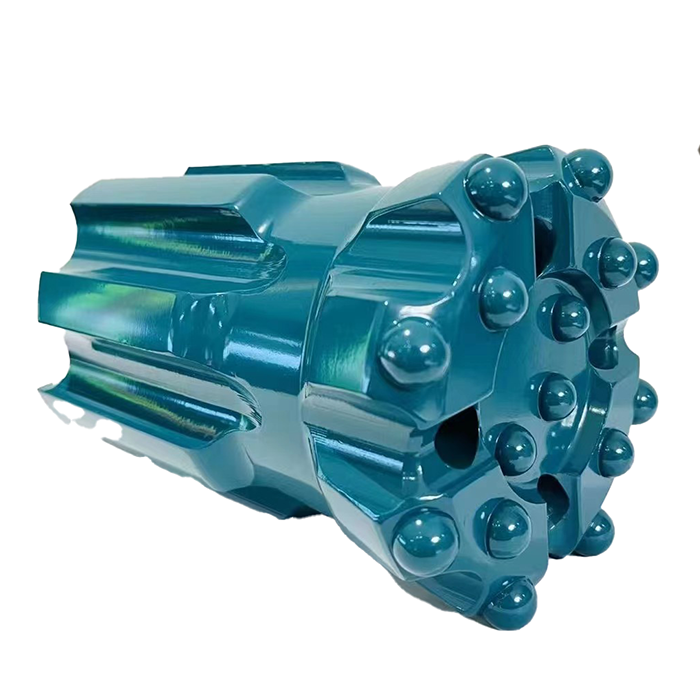

T51 retrac thread button bits T51 115mm drilling bits

Related reports:

Application of drilling bits Carbide Ball Teeth;

Instructions for using the drill bit;

Application of Carbide Ball Teeth button bits;

Retrac Threaded Button Bits T51 115mm: Precision in Rock Drilling for Mining and Drilling Operations

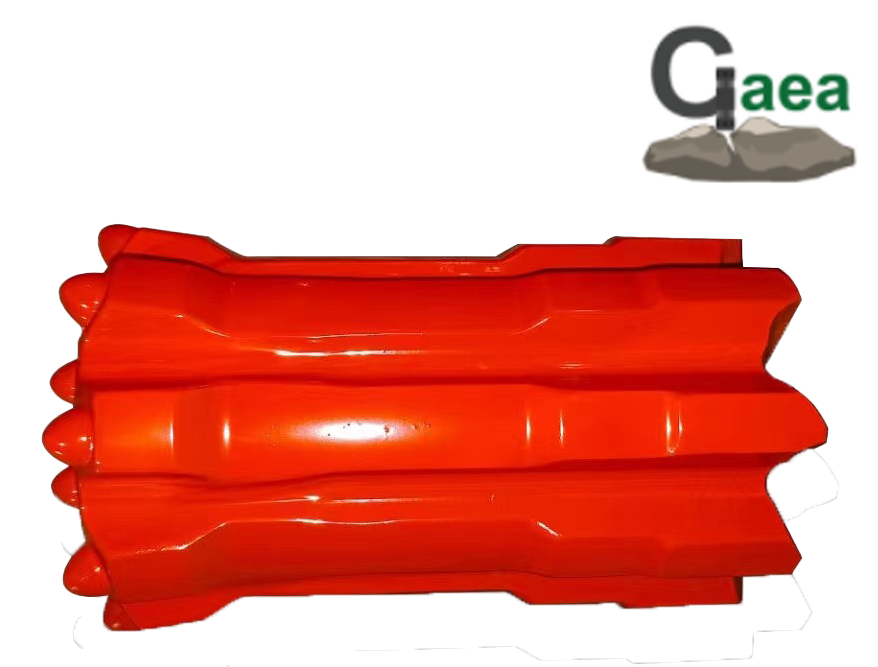

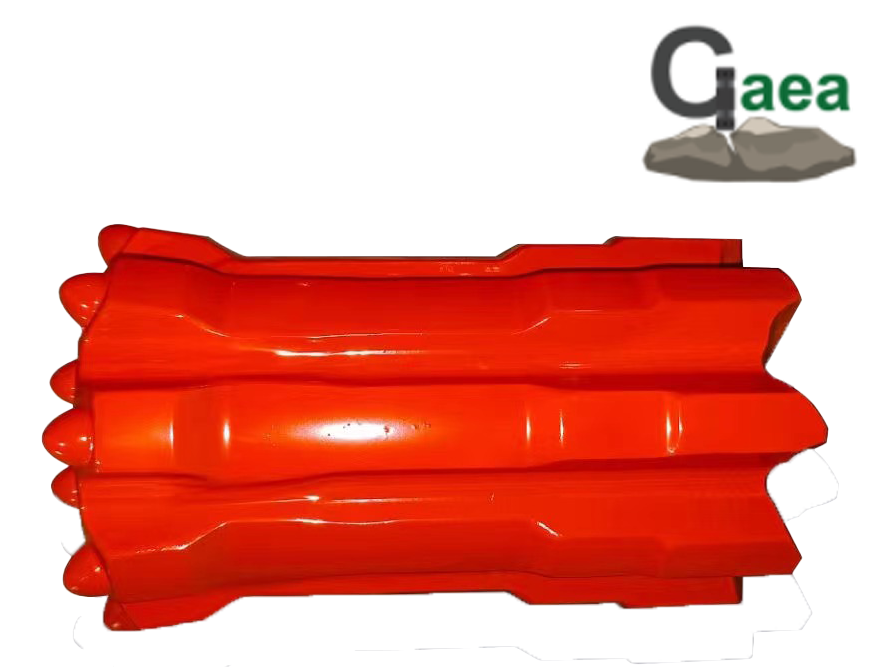

The common types of T series thread drill bits are mainly the following ones, and there is also one that is retrac.

Sunken type in the center of the picture: Low wind pressure is used to drill soft-medium hard and cracked rock formations. In order to obtain fast drilling speed and less blasthole deflection, this head shape is usually used.

Concave type: This head shape is suitable for all rock formations, especially in medium-hard and uniform rock formations. The blast hole deviation is small and the slag discharge effect is good.

Convex type: This shape is suitable for drilling soft to medium-hard rock formations when the wind pressure is low, and the steel body of the drill bit is not easily abraded. Its characteristic is that the load capacity of the side teeth is low. The wear is not serious and the rock drilling speed is fast, but the blast hole deviation is difficult to control.

Bilateral tooth type: This type of bilateral tooth type head is suitable for drilling very hard rock formations under high wind pressure. At this time, the drilling speed is fast and the wear of the drill bit body is not serious.

Flat type: This flat type head is suitable for drilling very hard rock formations and highly abrasive rock formations under high wind pressure. At this time, the drilling speed is faster and the drill body wears less.

Retrac drill bit: The easy-return drill bit includes a drill bit. One end of the drill bit is a cutting edge end provided with a cutting edge, and the other end of the drill bit is a mounting end. The outer wall of the drill bit is surrounded by multiple chip grooves. During rock drilling, the drill rig rotates and propels and high-pressure air is blown in from the bottom of the drill bit and out along the end of the chip flute, creating an upward airflow that makes rock drilling smoother and cleaner. The use of easy-return drill bits can smoothly discharge slag and improve work efficiency.

In the realm of rock drilling, precision and performance are paramount. The Threaded Button Bits T51 115mm, designed with a 115mm diameter and T51 threading, stand as a testament to excellence in the world of drilling equipment. These rock drilling bits, known for their rugged build and exceptional capabilities, find widespread use in both mining and drilling operations, making them indispensable tools for professionals in these fields.

Precision Engineering for Maximum Efficiency:

Threaded button bits T51 115mm are engineered with precision in mind. Their advanced design allows for efficient drilling through a variety of rock formations. The 115mm diameter strikes a balance between power and control, making them well-suited for a wide range of drilling tasks, from softer rock to more challenging hard rock.

Applications in Mining:

Mining operations demand the utmost in drilling precision, as safety and productivity depend on it. Threaded button bits T51 115mm are the answer to these demands. They excel in creating blast holes of precise dimensions, ensuring optimal explosive usage and controlled fragmentation. Furthermore, they play a vital role in exploratory drilling, aiding geologists and engineers in locating valuable mineral deposits.

Drilling Operations:

In the field of drilling, these bits prove their mettle in various applications, including geothermal drilling, water well drilling, and construction. Their versatility and durability make them a top choice for drilling contractors. Whether you are drilling for clean water, conducting environmental investigations, or constructing vital infrastructure, T51 115mm threaded button bits guarantee accuracy and efficiency.

Key Advantages:

Superior Penetration: Threaded button bits T51 115mm offer exceptional drilling speed and deeper penetration, significantly reducing project timelines.

Robust Versatility: These bits adapt seamlessly to a wide spectrum of rock types, excelling in everything from soft to the most challenging hard formations, making them versatile for various applications.

Precision Engineered: With an advanced button design, they ensure spot-on drilling accuracy, guaranteeing precise borehole placements for critical operations.

Long-Lasting Performance: Built to endure extreme drilling conditions, these bits exhibit remarkable durability, minimizing downtime and maintenance costs while maximizing productivity.