- Gaea

- 中国

- 5-25天

This kind of face shape is suitable for hard to very hard and abrasive rock formations in applications with high air pressures. Good penetration rates an resistance to steel wash.

T51 threaded drill bit is a commonly used drilling tool in the field of mining and civil engineering. It has the following product highlights:

The use of high-quality steel, advanced production technology and strong manufacturing capabilities ensure that the drill bit has high hardness and wear resistance.

The drill bit has a simple structure, a large outer diameter, and a wide range of applications. It can be used in various rocks and soils, and has high drilling speed and high efficiency.

Our T51 thread drill bit can meet the needs of different customers. It adopts independent research and development design and can be specially customized according to the different needs of customers.

Strict system testing and quality inspection ensure that the drill bit has the best quality and performance, long service life, and can quickly and accurately complete tasks in the harshest working environment.

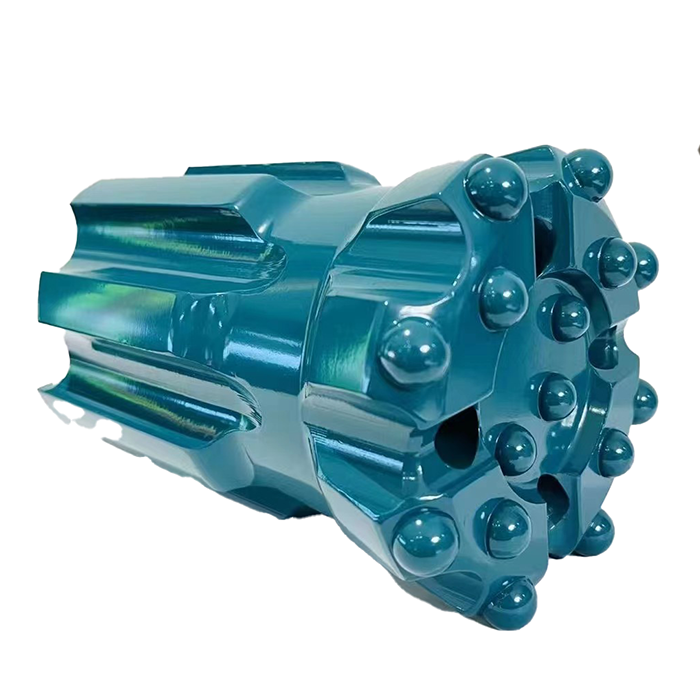

T51 Thread Button Bits 7degree Threaded Button Bit

Related Reports:

Instructions for using the drill bit;

The application prospect of deep hole threaded bit in the field of rock drilling is wide;

How to use the button bit more reasonable;

T51 thread drill introduction

The T51 thread drill bit is one of the most widely used models in the mining industry at present. It has superior durability and cutting ability, can adapt to various rock formations, and can improve production efficiency and reduce operating costs. T51 threaded drill bits are suitable for various formation types such as hard rock, semi-hard rock, brittle and tight rock.

Liaoning Gaea's T51 thread drill bit is produced with high-quality alloy steel and advanced manufacturing technology, which ensures the product's high precision and long life. Our drill bits are designed with a single prismatic profile that effectively reduces vibration and shock for more stable and accurate drilling. In addition, we have enhanced the wear resistance and fatigue strength of the product to ensure that problems during drilling are minimized.

Liaoning Gaea's T51 thread drill is equipped with a top hammer, which has a wide range of applications in fields such as mining and construction. This tophammer provides extreme impact and adhesion, enabling our T51 threaded bits to penetrate both harder and more fragile rock. At the same time, the drill bit has good directionality and stability, making the operation easier, safer and more reliable.

In conclusion, our T51 thread drill bit is a reliable tool in the mining industry. Its superior cutting ability, adaptability and durability can produce obvious results in various types of formations. Purchasing our T51 thread drill product line can help you increase efficiency, minimize maintenance costs and achieve superior drilling results. If you are interested in this product or other brazing tools products, please contact our sales representative for more detailed information about this product.

Key Specifications/Special Features:

Bit face shape selection:

1. Drop Center Bit

For high penetration rates in soft to medium hard and fissured rock formations. Low to medium air pressures. Maximum hole deviation control.

2. Concave Face

The all-round application bit face specifically for medium hard and homogenerous rock formations. Good hole deviation control and good flushing capacity.

3. Convex Face

For high penetration rates in soft to medium-hard with low to medium air pressures. It is the most resistance to steel wash, and may reduce the load and wear on the gauge buttons, but poor hole deviation control.

4. Double Gauge Face

This kind of face shape is suitable for fast penetration rates in medium to hard rock formations. Designed for high air pressures and good resistance to steel wash step gauge bit.

5. Flat Face Bit

This kind of face shape is suitable for hard to very hard and abrasive rock formations in applications with high air pressures. Good penetration rates an resistance to steel wash.

Carbide button shape selection:

1. Domed/Round Button

2. Parabolic/Semi-Ballistic Buttons

3. Ballistic Button

4. Sharp Button

5. Flat Button

Feature:

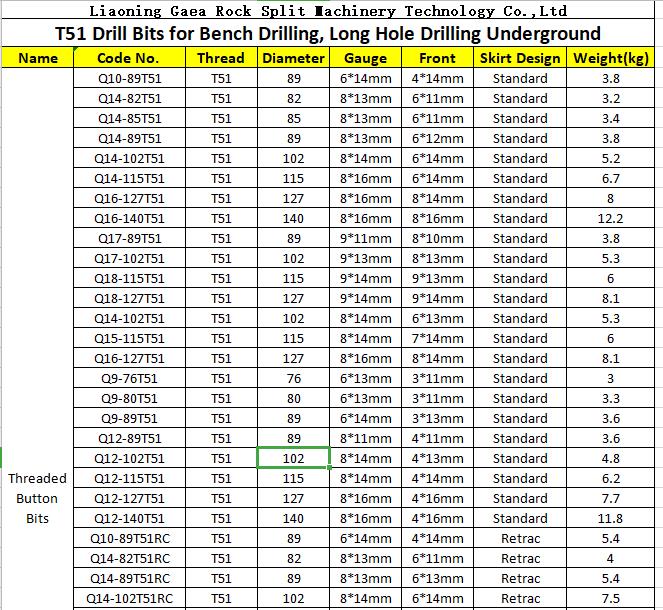

· Code No.: Q13-89-T51

· Thread: T51

· Diameter: 89mm

· Gauge Buttons: 8

· Front Buttons: 5

· Carbide Design: Dome

· Face Design: Drop Center

· Skirt Deign: Standard

Diameter: 76mm, 89mm, 102mm

Skirt body: retrac, and normal, straightrac

Face type: flat, uniface, Drop Center

Carbide shape: Dome, ballistic, semi-ballistic

Used in bench drilling, underground long hole drilling to match extension MF rod, MM rod heavy duty top hammer drilling tools.

Drop Center Face T51 Threaded Button Bit

Dome Button T51 Threaded Button BitT51 Threaded Drill BitT51 Threaded Drill Bit

13 Dome carbide inserts T51 threaded drill bit with drop center face design, 89 mm diameter match with extension drill steels. Drop center bits (DC) are well suited for drilling straighter holes in less abrasive and less consolidated rock at a faster rate.