- Gaea

- China

- 3day

- 3000pcs/month

Gaea Rock professional in manufacture extension rod.T38 T45 T51 GT60.length including 1830-5525mm.

T51 extension drill rod MM MF top hammer drilling tools drill pipe

Related reports:

Prepare the tapered drill rod before use;

Installation and heat treatment technology of spiral drill pipe;

Instructions for use of threaded drill rods;

T51 Extension Rod introduction:

The T51 Extension Rod, also known as a drilling rod, is a hollow cylindrical or hexagonal rod with threaded connections on one or both ends, serving as the main component of the threaded drill string assembly.

The T51 Extension Rod is designed to meet the specific requirements of drilling and blasting operations. Its threaded connections allow for quick and efficient assembly and disassembly, facilitating fast drilling speeds and minimizing energy losses during impact transmission. This superior performance contributes to improved drilling efficiency and the mechanization of rock excavation, thereby enhancing overall drilling conditions.

With its exceptional characteristics, the T51 Extension Rod has become an increasingly significant component in the manufacturing and utilization of drill string assemblies. Its versatility, wide range of specifications, and larger quantities make it a cost-effective and essential tool in the field. In fact, the T51 Extension Rod is now considered a dominant product within the drilling tool industry, thanks to its various advantages.

The T51 Extension Rod finds extensive applications in drilling and blasting projects, including mining, quarrying, and other rock excavation activities. It is compatible with hydraulic rock drilling rigs and other drilling equipment, delivering excellent performance in challenging rock formations. Its high-quality materials, such as premium alloy steels, combined with precise manufacturing processes, ensure its durability and reliability even under harsh working conditions.

At Liaoning Gaea, we prioritize product quality and adhere to international standards throughout the manufacturing and quality control processes of our T51 Extension Rods. We strive to deliver products that meet and exceed our customers' expectations. Additionally, our experienced team provides comprehensive after-sales support, including technical guidance and assistance, ensuring a seamless customer experience.

In conclusion, the T51 Extension Rod, also referred to as a drilling rod, is a versatile and indispensable component in drilling and blasting operations. Its threaded connections enable fast drilling speeds, efficient energy transmission, and improved rock excavation conditions. As a result, the T51 Extension Rod has gained significant prominence in the drilling tool industry, with a wide variety of specifications and a large-scale production volume. With its exceptional performance and our commitment to quality, Liaoning Gaea remains dedicated to providing high-quality T51 Extension Rods to meet the diverse needs of our valued customers.

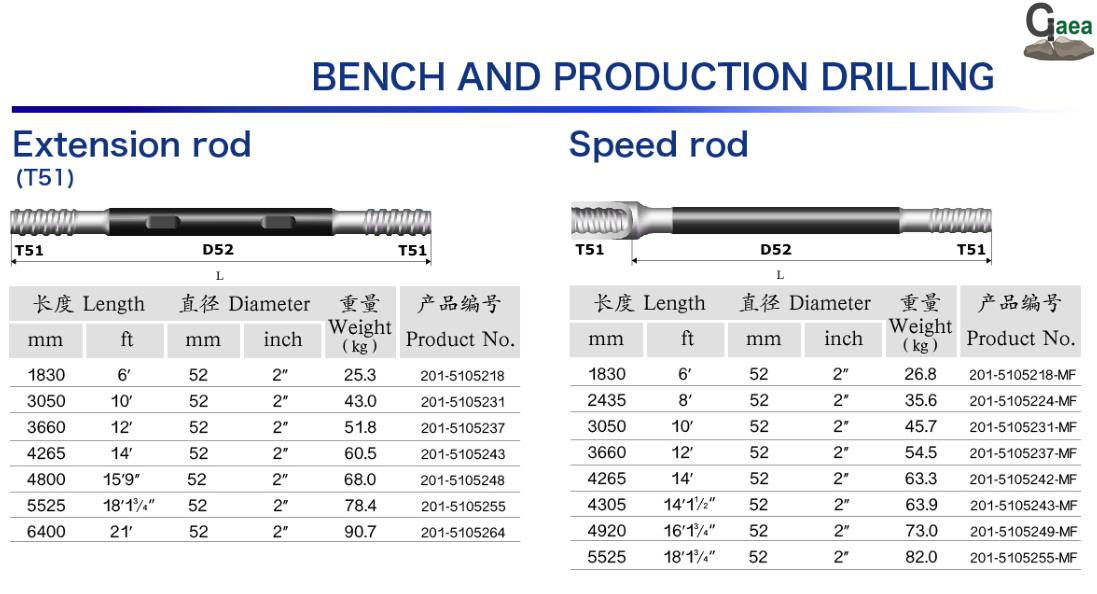

This is the specification about T51 extension rods(drill pipe):

The drill pipe(extension rod) is a steel pipe with a thread on the tail, which is used to connect the surface equipment of the drilling rig and the drilling and grinding equipment or bottom hole device at the bottom of the well. The purpose of the drill pipe is to transport the drilling mud to the drill bit and raise, lower or rotate the bottom hole device together with the drill bit. During the rotation of the drill pipe, it must be able to withstand large torques, twists, bends and vibrations. During the drilling process, the drill pipe can be used multiple times.

The operating procedures of the drill pipe(extension rod) are as follows:

1. Align the hole position. Do not operate the drill pipe, but be careful not to "don't" the drill pipe.

2. Release the drill. Under the action of the gravity of the drill pipe and the drill tool, the process of overcoming the friction force of the hole wall and the buoyancy of the mud and realizing the extension of the drill pipe is called release drilling. The correct drilling sequence is as follows: the outer rod is lowered in place, and the adjacent inner rods begin to extend from the outer rod, from the outside to the inside, one by one.

3. Drill, pressurize, and drill forward at an appropriate rotation speed.

4. Unload the entire bottom of the soil. Be careful not to "don't" the drill pipe when unloading the soil and closing the bottom. Note: When drilling with friction drill pipes, each time includes five sequences of "positioning the hole, setting the drill, drilling, lifting the drill, unloading the soil and closing the bottom". It is necessary to achieve "not falling order", "not disorderly order", and "not increasing order at will".

Drill pipe abrasive wear performance form

Abrasive wear is a phenomenon in which external hard particles or micropeaks on hard surfaces cause surface scratches and surface material shedding during the relative movement of the friction pair's surface. The surface characteristics of the drill string are scratches, tears, and longitudinal tension. Marks, local flaking and cracks.

The abrasive wear mechanism is micro-cutting, and multiple plastic deformations lead to fracture and micro-fracture. The drill pipe string is prone to bend in a state of compound stress, and severe friction occurs between the protruding part and the hard rock layer after bending. The quenching treatment thickness of the drill pipe string surface is generally 1mm. After the quenching layer is worn away, the subsequent wear rate will increase. In deep hole drilling, sometimes there are obvious scratches on the surface of the drill pipe taken out, which is the performance of abrasive wear.

Explanation on the conditions of use of drill rods(extension rod):

1. The rated torque of the selected drill pipe should be greater than the large torque of the drill rig. The rotation speed of the drilling rig should be less than the rotation speed of the drill pipe (the impact of the drilling tool moment of inertia on the drill pipe is less than the rated torque of the drill pipe).

2. In a certain stratum, when the sum of the weight of the drill pipe is completely out of reach, the drill teeth of the drill tool are not allowed to penetrate into the original soil layer, and the friction drill pipe is not allowed to drill.

3. When using friction drill pipe to drill oblique holes, it must be well guided in the direction of expansion and contraction of the drill pipe when the protective tube and drilling tool are used, and the angle between the center lines of the pipe sections is not allowed to exceed 0.4 degrees.

4. Drilling a vertical hole with a drilling incline that exceeds the "JTJ041-2000 Highway Bridge and Culvert Construction Technical Code" stipulated in the hole incline, it is easy to cause damage to the friction drill pipe.

Logistic packaging: