- Gaea

- China

- 5-25天

Produce Hexagonal and round cross sections, Hexagon rods are more rigid, heavier and transfer energy more efficiently, while increasing flushing. Round rods are generally lighter than hexagonal rods and are normally used in extension drilling applications.

Drifting Drill Rod Rock Drill tools extension rod MF MM T38 T45 T51 GT60

Related reports:

How to ensure the quality of blast furnace drill pipe;

Correct cleaning method of drill pipe for underground mining;

What are the effects of incorrect use of drill rods;

Extension rods introduction:

Welcome to Liaoning Gaea, your trusted provider of high-quality extension rods, also known as drill pipes or threaded drill rods. Our extension rods are essential tools in various industries, serving as a crucial component in connecting drill bits, hydraulic rock drills, and threaded drill heads. With their robust design and reliable performance, our extension rods enable the transmission of impact force and rotational power from hydraulic rock drills to the threaded drill heads, facilitating efficient rock breaking operations.

Key Features:

Threaded Connection: Our extension rods feature a threaded connection, allowing for secure and efficient assembly with drill bits, hydraulic rock drills, and threaded drill heads. This threaded connection ensures a reliable and sturdy link, enabling the smooth transfer of power and force during drilling operations.

Versatility and Compatibility: The extension rods are highly versatile and compatible with a wide range of hydraulic rock drilling systems. They are commonly used in conjunction with hydraulic rock drilling rigs and drilling carriages, making them an integral part of various applications, including open-pit mining, underground mining, tunnel excavation, anchoring projects, blast furnace tapping, tunneling projects, hydropower engineering, quarrying, and other construction projects.

Extensive Thread Options: Our extension rods are available in a variety of thread forms to suit different drilling requirements. Some of the commonly used thread forms include R22, R25, R28, R32, TR35, T38, T45, T51, ST58, ST68, T60, EL60, and EL68. These thread forms ensure compatibility with specific drilling systems, providing flexibility and convenience for different project needs.

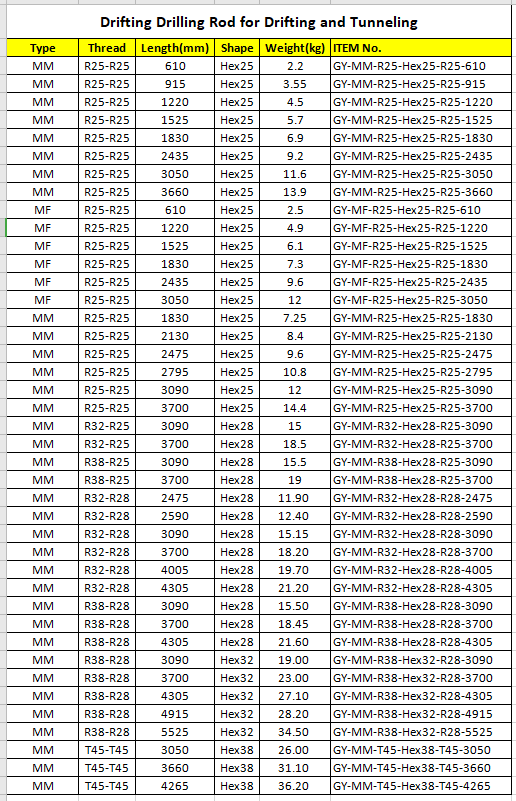

Types of Extension Rods: We offer two types of extension rods to meet diverse drilling needs. The first type is the quick-change extension rod (MF drill rod), which allows for rapid tool changes, enhancing operational efficiency. The second type is the coupling extension rod (MM drill rod), which provides a reliable connection between the various components of the drilling system, ensuring stability and consistent performance during drilling operations.

Applications:

Open-Pit Mining: Extension rods play a vital role in open-pit mining operations, enabling efficient and precise drilling for mineral extraction. Their compatibility with hydraulic rock drilling systems ensures optimal performance in challenging mining environments.

Underground Mining: In underground mining, extension rods are essential tools for tunneling and ore extraction. They provide reliable support for hydraulic rock drills, allowing for efficient drilling in confined spaces and tough geological conditions.

Tunnel Excavation: Extension rods find extensive use in tunnel excavation projects, where they facilitate the drilling of blast holes, anchor holes, and other essential holes for tunnel construction. Their durability and compatibility contribute to the smooth progress of tunneling operations.

Anchoring Projects: For anchoring applications in construction projects, extension rods provide a secure connection between anchor bolts and drill heads. They enable precise drilling for effective anchoring and stabilization of structures.

Blast Furnace Tapping: In blast furnace operations, extension rods are utilized to create tapping holes for the controlled release of molten iron. Their reliable performance and compatibility with hydraulic rock drilling systems ensure safe and efficient tapping processes.

Hydropower Engineering: Extension rods are crucial in hydropower engineering projects, where they facilitate the drilling of holes for anchor installation, foundation preparation, and other essential tasks. Their compatibility with drilling systems ensures accurate and reliable drilling, contributing to the successful completion of hydropower projects.

Quarrying and Construction: In the quarrying industry, extension rods are widely employed for stone extraction and drilling operations. Their robust construction and compatibility make them indispensable tools for creating precise holes and facilitating the extraction of high-quality materials.

Conclusion:

At Liaoning Gaea, we are committed to delivering top-quality extension rods that meet the diverse needs of the mining, tunneling, anchoring, and construction industries. Our extension rods boast reliable threaded connections, extensive compatibility, and exceptional durability, ensuring efficient and precise drilling operations. Whether for open-pit mining, underground excavation, tunneling projects, or other applications, our extension rods provide the reliable performance you need. Contact us today to learn more about our extensive range of extension rods and how they can enhance your drilling processes.

Gaea Extension Rod(drifting drilling rod)

Produce Hexagonal and round cross sections,Hexagon rods are more rigid, heavier and transfer energy more efficiently, while increasing flushing. Round rods are generally lighter than hexagonal rods and are normally used in extension drilling applications. With the longer steel tending to be larger in diameter, conventional extension steel is characterized by a duplicate thread on each end of the steel.

Heat treatment:

Threaded process:

Male/Female (M/F) rod, speed rod

M/F drill steel is an alternative to couplings sleeves to include the female part of the threaded connection as an integral part of the drill steel. M/F drill steel provides more rigid connections and is easier to uncouple and handle. The service life also tends to be better than with separate couplings. The advantages of drilling with M/F steel include: Easy handling, quicker uncoupling, tighter connections, the potential to drill straighter holes, and longer service life.

Feature and Advantage

For Extension Rod and M/F steel process, the below two different types of heat treatment are used to strengthen high speed and powerful percussive drill string components to maximize their performance and reliability. Longer steel larger in diameter, conventional extension steel, Hexagonal and round cross sections are available.

- Carburization is a process used to harden the entire rod surface both internally and externally to strengthen and extend the life of the rod.

- High Frequency Induction is a process where only the thread ends of the rod are hardened to lengthen thread life.

Steel grade: 23CrNi3Mo equivalent to SANDBAR 64

SIZE: Hex. 22mm. Hex. 25mm, hex. 28mm. Hex. 32mm hex. 35mm

Dia. 32mm. Dia. 38mm, dia. 45mm dia. 51 mm

Thread: R22, R25, R28, R32, R38, T38, T45, T51, ST58, T60

Length: 0.4m-10m

Package: In wooden case or in bundles.

Packaging: