- Gaea

- 中国

- 5-25天

CO2 rock blasting system is a set of machine to use in rock blasting,rock demolition,quarrying,tunnel,underground explosive and so on.

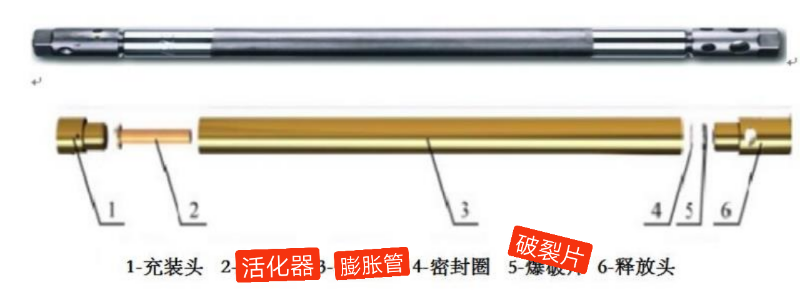

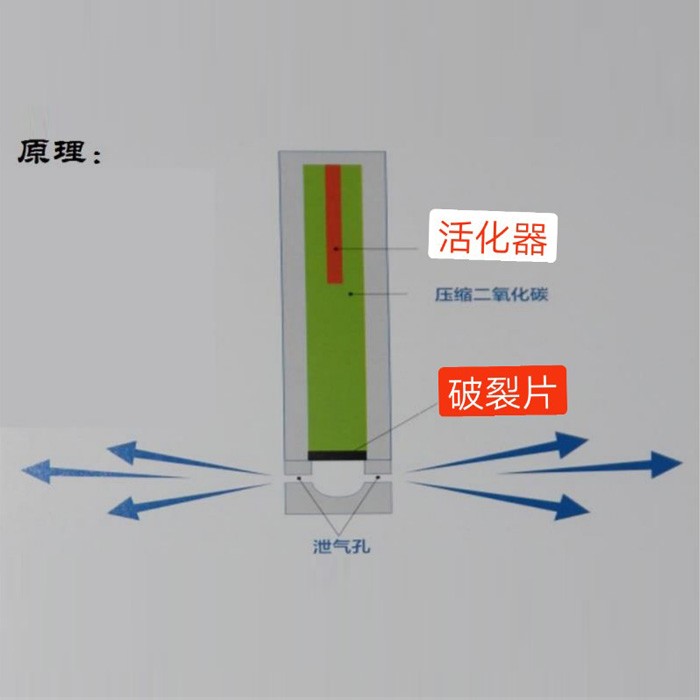

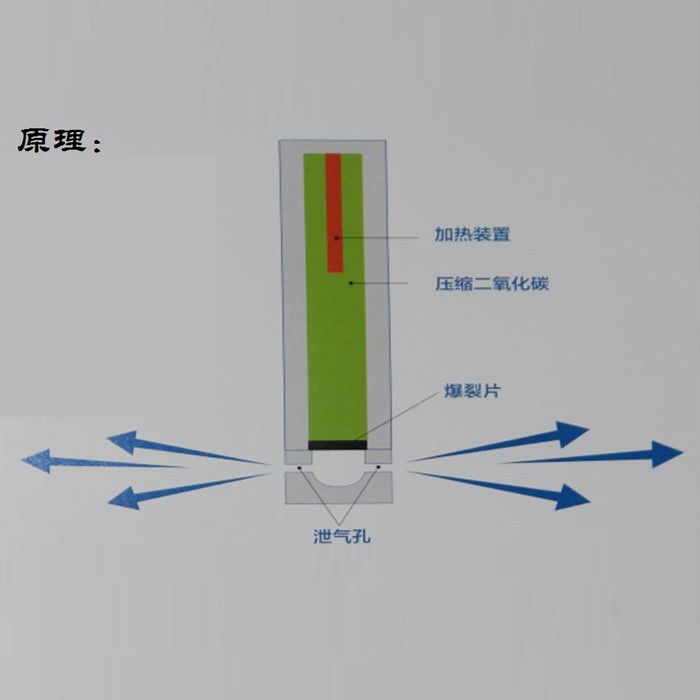

the Gaea CO2 rock blasting system consists of a high-strength, reusable steel tube filled with liquid carbon dioxide, a chemical energiser, and a rupture disc. When the Gaea CO2 rock blasting tube tube is ignited, the carbon dioxide is almost instantaneously converted from a liquid to a gas

CO2 rock blasting system Gas Cracking Heating Tube Drilling Blasting Quarry Blasting Rock Excavation

New technology: O2 rock demolition system

Link:

Related reports:

In what fields can carbon dioxide gas rock blasting technology be applied?;

Operation Introduction of CO2 Rock Blasting Technology: A Safe and Efficient Excavation Method;

Is the domestic technology of carbon dioxide blasting mature? ;

CO2 rock blasting system is a set of machine to use in rock blasting,rock demolition,quarrying,tunnel,underground explosive and so on.

Developed over 60 years ago for use in explosive coal seams in the UK,This technology is mature in Chin. the Gaea CO2 rock blasting system(rock hole drill) consists of a high-strength, reusable steel tube filled with liquid carbon dioxide, a chemical energiser, and a rupture disc. When the Gaea CO2 rock blasting tube tube(rock hole drill) is ignited, the carbon dioxide is almost instantaneously converted from a liquid to a gas.

Pressure is released from the gaseous CO2 up to 300mpa (3000 bar), it expands through microcracks and fractures the rock. The pressure can be regulated between 1200 and 2800 bar by using rupture disks. Figure 1 shows a schematic diagram of the components which make up the cartridge. The body is filled with liquid CO2, a safety heater inserted in the firing head, a rupture disk in the discharge end of varied thickness to regulate pressure.

A nylon collar is used to hold the cartridge in place so no stemming is required. The chemical energiser is activated by a small electrical charge which causes detonation(dexpan rock breaking).

CO2 rock blasting system (CO2 gas blasting device) is a special device that uses high-pressure carbon dioxide gas to generate explosive force. It has a wide range of applications in many fields, including building blasting, mine blasting and quarrying.

In the field of building blasting, carbon dioxide gas blasting devices play an important role. It can be used to remove supporting structures, concrete columns, walls and other strong structural elements of buildings. There are several advantages to using CO2 rock blasting system for blasting work. First of all, carbon dioxide gas is relatively safe and will not cause too much harm to the surrounding environment and personnel. Secondly, the generation of dust and debris is reduced during the blasting process, which reduces the impact on the surrounding environment and personnel. This makes CO2 rock blasting system a cleaner and more efficient method of building blasting.

In terms of mine blasting, CO2 rock blasting system also play an important role. In mines, blasting is one of the common methods of mining ore. The CO2 rock blasting system can produce powerful explosive force, which is used to break rock and ore, so as to facilitate subsequent mining work. Compared with traditional explosive blasting, CO2 rock blasting system are more environmentally friendly. It produces no harmful gases, fumes or toxic residues, reducing risks to miners and the environment.

Quarries are also one of the application fields of CO2 rock blasting system. Quarries often need to break large pieces of rock to obtain the required stone. The CO2 rock blasting system can efficiently break rocks and improve quarrying efficiency. In addition, the use of CO2 rock blasting system for stone mining has the advantage of being environmentally friendly. Compared with traditional blasting methods, it reduces the generation of dust and noise, and is conducive to maintaining the surrounding ecological environment.

FAQ:

1. What are the maintenance requirements for a CO2 rock blasting system?

Answer: Regular maintenance, including inspection, cleaning, lubrication, and replacement of worn components, is necessary to ensure the optimal performance and longevity of a CO2 rock blasting system.

2.Can the CO2 gas used in the system be sourced locally?

Answer: Carbon dioxide gas can often be sourced locally through gas suppliers or industrial gas companies, ensuring convenient access for refilling or replacing gas cylinders.

3.Is there a limit to the depth or thickness of rocks that a CO2 rock blasting system can effectively break?

Answer: The effectiveness of the CO2 rock blasting system can vary depending on the specific equipment model and the characteristics of the rock. It is advisable to consult with the manufacturer or supplier for specific depth or thickness limitations.