- Gaea

- 中国

- 5-25天

- 100sets/month

CO2 rock demolition system(rock breaking)is a new technology which can replace soundless cracking agency and explosive.

Extensive has two aspects. First, there are many sources of carbon dioxide in raw materials, which are widely available and are easy to buy. Second, Expansion cracking rock technology of carbon dioxide is widely used. Ground engineering for open pit mining, open pit stripping, road construction, foundation pit excavation, tunnel construction, stone mining, gas drainage, deep hole pre-cracking building demolition, pipeline blocking, dredging, underwater blasting, source testing, film and television effects and many more.

CO2 Rock demolition Breaking System Expansion Cracking Rock Device Blasting Rock Drilling And demolition

New technology: O2 rock demolition system

Link:

https://www.stonedemolition.com/product/o2-gas-energy-rock-splitting-system-co2-rock-blasting-system-rock-demolition

Related reports:

Safety measures and precautions for static rock blasting;

Drilling requirements for drilling tools in blasting hole drilling operations;

CO2 rock demolition system(rock breaking)is a new technology which can replace soundless cracking agency and explosive.

Expansion Cracking Rock Technology of Carbon Dioxide

----professional rock breaking and rock demolition solutions;rock breaking(rock demolition) equipment;

I. Introduction to expansion rock blasting methods(rock breaking machine) of carbon dioxide

As is known to all that explosive blasting(rock blasting methodology) is one of the main causes of major accidents. Gas explosions caused by explosive blasting account for more than 40% of such accidents (also accounting for more than 30% of all coal mine gas and dust explosion accidents). In the case of gas, water accumulation and concentration of ground stress in the blasting area, the blasting can also cause gas outburst, even gas explosion, water inrush disaster (more than one-fifth of the coal mine water inrush is caused by blasting), impact ground pressure(controlled rock drilling and blasting), etc. . In other fields, when explosives are blasted, they often cause great damage to surrounding buildings and people. For example, it can cause the collapse of a building(blasting process), the destruction of a transmission line, and the loss of human life. This is determined by the characteristics of the explosive. The explosive explosion process is completed in a very short time. The instantaneous chemical reaction produces a powerful impact (above 1000 Mpa-5000 Mpa). This impact can form strong vibrations and reach the intensity of "earthquakes above the third level", even several kilometers away.

In the longer term, since the great Swedish scientist Nobel invented the explosives in 1864, the ability of mankind to fight against the earth has developed rapidly. With the extension of a series of railways, the rise of cities and human civilization has been unprecedented development; however, explosives are also Nobel’s regrets and human regrets. Because of the moment when the explosives were invented, this regret appeared. At that time, Nobel’s youngest brother and four other inmates were killed. From then on, to 2016, a total of 152 years, hundreds of millions of people (including war) died of explosives. This is the regret of mankind. The establishment of the Nobel Prize, I think it is a regret of Nobel---- Today, we can finally say that these two regrets can be prepared to end.

Expansion cracking rock technology(rock breaking machine) of carbon dioxide was born! It has the advantage of explosives(rock demolition), without shortcomings of explosives. This is a huge leap in the advancement of human technology. From then on, we can start, in the field of civil blasting, begin to eliminate the danger of explosives. Expansion cracking rock technology(CO2 rock demolition technology) of carbon dioxide cannot cause such disasters. The reason is that the expansion cracking rock technique of carbon dioxide is not blasting first, but the exact point is “expansion cracking rock”, because the original concept of blasting is for explosive blasting(rock demolition). The expansive cracking rock itself(CO2 rock demolition system process) is an endothermic process. Without high temperature, it cannot detonate gas and other combustible gases, causing accidents. At the same time, the process of expansion rock cracking is much longer, reaching several milliseconds, even tens of milliseconds, and the instantaneous impact force is about 400 Mpa. Therefore, the same rock is cracking, and the second expansion rock is driven by continuous force and endurance. If explosive blasting relies on "instantaneous explosive force", carbon dioxide expansion is due to "endurance." Therefore, the detonation velocity of carbon dioxide expansion cracking rock is only about 3 m/s, and the disturbance and impact on the surrounding rock and environment are much smaller. According to the test results, the carbon dioxide expands the cracking rock, and within a few meters, there is no damage.

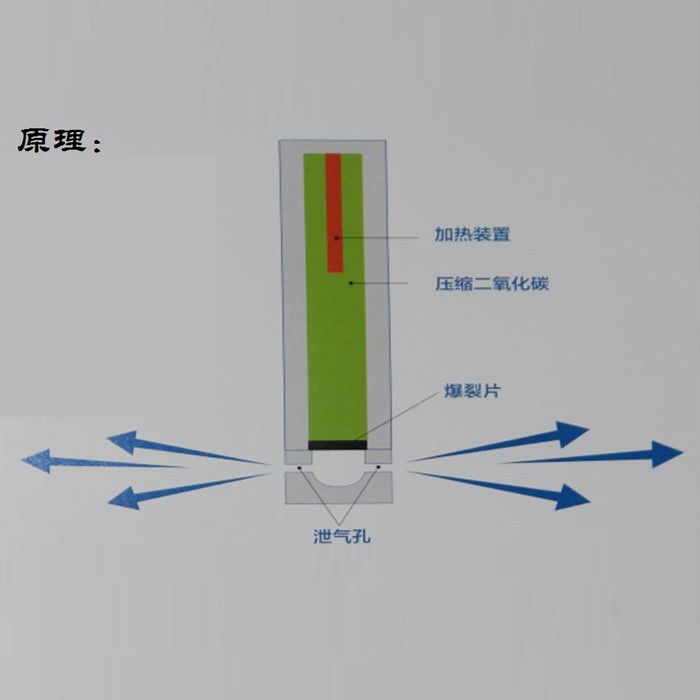

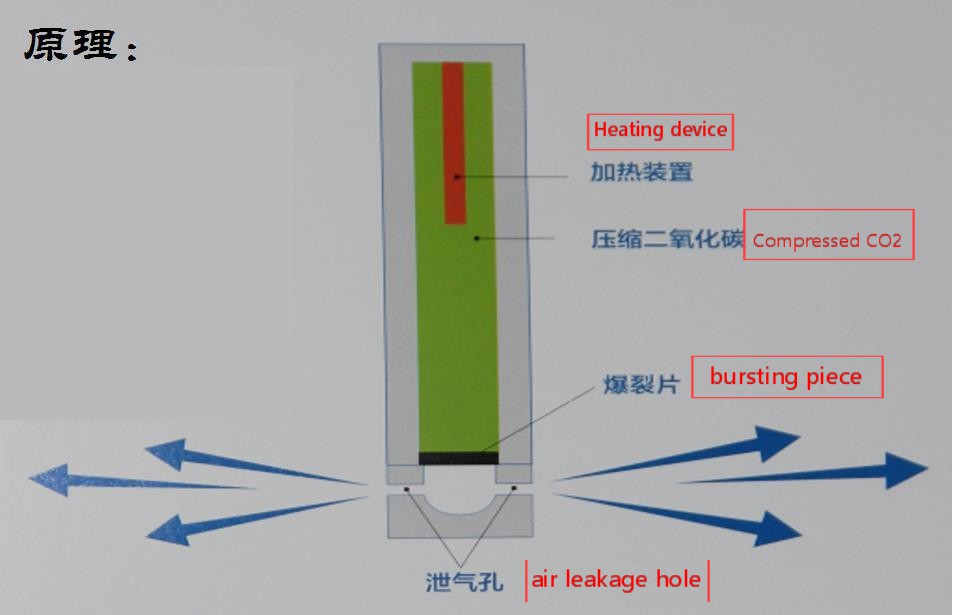

ⅡThe principle of expansion cracking rock technology of carbon dioxide(rock demolition process)

The principle of expansion cracking rock technology of carbon dioxide is to use the principle of rapid gasification and expansion under the condition of sudden rapid heating of liquid carbon dioxide, and to generate strong impact force. Through proper control, the rock breaking effect is caused. Specifically, first, the liquid carbon dioxide is charged into the expansion tube by using a filling machine (and a rupture piece, an activator, etc.), and the expansion tube is placed in the blast hole, and the blast hole is tightly sealed; then the igniter is used for activating the activator inside the expansion tube to rapidly expand the liquid carbon dioxide by 1000-2000 times under rapid heating conditions. The strong impact force (200-400 Mpa) first breaks through the rupture piece and then quickly moves along the set vent hole. After rushing out, due to the closed hole, it cannot be freely leaked, thus causing expansion shock to the surrounding rock, causing cracking effect and forming rock breaking effect (as shown in Figure 1)

Figure 1: Schematic diagram of intelligent carbon dioxide cracking system

Heating device Compressed CO2 bursting piece air leakage hole

ⅢThe advantages of Expansion cracking rock technology of carbon dioxide(types of blasting methods)

Expansion cracking rock technology of carbon dioxide has the following advantages:

Ⅰ) Security

The biggest advantage of carbon dioxide expansion rock technology is in several aspects:

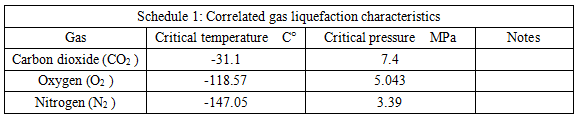

1. Carbon dioxide has excellent chemical and physical properties and is very safe. The molecular formula of carbon dioxide is CO2, the chemical valence has been stabilized, and it can no longer participate in chemical reactions. It is a true inert gas. Therefore, during the entire expansion process, only liquid carbon dioxide to vaporized carbon dioxide, no harmful substances are produced. Some people say that nitrogen is used, and air can be used. However, in contrast to carbon dioxide, the two gases, both in terms of chemical, physical properties and source, have obvious disadvantageous. From a chemical point of view, the chemical price of nitrogen is unstable. For example, when it is expanded, it can also chemically react with oxygen to form toxic gases such as nitrogen monoxide and nitrogen dioxide. From a physical point of view, because of the high critical temperature of carbon dioxide, it is certainly easier to liquefy carbon dioxide than nitrogen and air (such as the attached table), so the transportation and storage of carbon dioxide is much easier. In addition, carbon dioxide is an industrial waste gas that is already present and stored, and others need to be prepared and consume energy.

2. There will be no explosion in production, storage and transportation. Combustible liquefied gas is easy to leak, and it is exposed to fire and explosion. Carbon dioxide can't be burned. If it leaks, it can only deflate. Because it absorbs a lot of heat, it may cause local freezing around it and will not explode. Of course, if you deflate in a closed space, you may cause carbon dioxide to exceed the standard, causing suffocation.

3. Suit for underground drilling and blasting.Expansion cracking rock(rock demolition) technology of carbon dioxide is the expansion of cracking rock, the so-called "expansion" is the process of carbon dioxide cracking is a liquid into a gaseous state, so absorb a lot of heat around, so that the surrounding environment is cold, will not detonate gas and coal dust. This feature is especially suitable for blasting operations in explosive gas and dust environments such as coal and coal dust, such as coal mines and oil mines. This is a huge positive and comprehensive application, which will reduce major accidents in coal mines by more than 50%.(blasting contractors)

4. The vibration generated by the expansion cracking rock(rock demolition) technology of carbon dioxide is weak, and the destructive power is very small. It is very powerful for protecting buildings and less induced ground pressure induced factors. The detonation speed of expansion cracking rock(rock demolition) technology of carbon dioxide is much lower than that of explosive detonator blasting. The impact force is generally 400 Mpa, which is far lower than 1000-5000 Mpa of explosive blasting. According to the initial test detonation speed of about 3 m / s, generally after leaving the blasting point 2-3 meters, there is basically no destructive effect.

(rock demolition and overbreak control)

5. No new harmful gas is generated during expansion. Unlike explosive gas, which generates a large amount of harmful gases such as carbon monoxide, carbon dioxide cracking is a physical reaction process. From liquid carbon dioxide to vaporous carbon dioxide, it is completely harmless to start on the ground. The engineering detections have never exceeded the standard above one meter height, and there is a short-term over-standard phenomenon (normal ventilation) near the floor of the roadway.

6. No using for terrorist activities. On the one hand, because carbon dioxide cannot burn, it cannot explode. On the other hand, Expansion cracking rock(rock demolition) technology of carbon dioxide must produce expansion at a closed pressure of 4 MPa, and it can be placed in the open air without causing destructive effect. Therefore, it cannot be used in terrorist bombing cases. Therefore, the promotion of smart expansion cracking rock technology of carbon dioxide will have a positive impact on anti-terrorism and counter-terrorism.

Ⅱ) Reducing trouble

It reduces many troubles for the state and the society. First, there is no need to worry about the major mega-security accidents. Second, because there is no need to worry about the resulting terrorism. On the contrary, the application of carbon dioxide expansion and rock cracking technology can greatly reduce major and large safety production accidents, the occurrence of anti-terrorism cases, and the difficulty of anti-terrorism and anti-terrorism. It is an industry that the country will vigorously advocate for development.

Ⅲ) Environmental protection

The contribution of carbon dioxide expansion rock technology to environmental protection is mainly as follows:

First, the use of waste gas from chemical plants or coal-fired power plants is the reuse of waste gas. Carbon dioxide is an existing item that does not need to consume energy to produce. Therefore, unlike explosives and other gas production, it will cause new pollution. Second, the carbon dioxide expansion cracking process, unlike explosives, produces a large amount of toxic and harmful gases such as carbon monoxide, as well as a large amount of dust. Third, the noise is very small, the vibration is very small, and there is basically no noise pollution.

Ⅳ) “Tongwei”

So-called “Tongwei” is almost the same power as the explosive explosion. This should be viewed from two aspects. First, it is the same in terms of the destructive power of the rock breaking(rock demolition) force. Although the impact force of the carbon dioxide expansion cracking rock is about 400 Mpa, it is much smaller than the explosive. However, the action time of the explosive explosion is instantaneous, and the time of carbon dioxide cracking rock can be greatly extended by several milliseconds or even longer. If the explosives are to work on the 'explosive power', then the carbon dioxide expansion cracking rock is to rely on 'endurance' to work, and time can be used to supplement the 'explosive power' small defects. Second, in terms of engineering accident capability, explosive blasting is generally a 'gluttony', a bite to eat a fat man, a large-scale blasting with dozens of tons, or even hundreds of tons of explosives, blasting tens of thousands, even dozens of hundreds tons of rock, and then, slowly transported. The technology of carbon dioxide expansion and rock cracking is “gnawing-away”, which is ‘chewing slowly,’ now a set of equipment (need to be equipped with enough expansion tubes), day and night construction, and can break 20,000 cubic meters a day. With multiple sets of equipment, you can meet the needs of large-scale mining(controlled rock blasting).

V) Extensive

Extensive has two aspects. First, there are many sources of carbon dioxide in raw materials, which are widely available and are easy to buy. Second, Expansion cracking rock technology of carbon dioxide is widely used. Ground engineering for open pit mining, open pit stripping, road construction, foundation pit excavation, tunnel construction, stone mining, gas drainage, deep hole pre-cracking building demolition, pipeline blocking, dredging, underwater blasting, source testing, film and television effects and many more,blasting in underground mines.

Ⅵ) Low price(rock blasting services)

From a comprehensive perspective, the cost of expansion cracking rock technology of carbon dioxide is lower than the cost of explosive blasting. The cost of anti-terrorism and the cost of anti-terrorism are zero. The application of explosives and other explosives has produced huge anti-terrorism and anti-terrorism costs, and the high cost of the society is not the expansion cracking rock technology of carbon dioxide. Comprehensive analysis, from a national perspective and from a social perspective, the comprehensive cost of expansion cracking rock technology of carbon dioxide has been lower than the cost of explosive blasting.

Ⅳ The composition and basic operation steps of expansion cracking rock technology of carbon dioxide

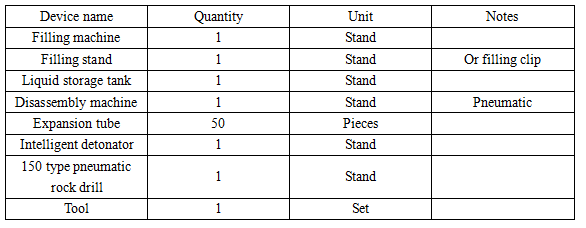

Ⅰ) System composition

The open-air carbon dioxide expansion rock technology consists of ground-operated equipment.

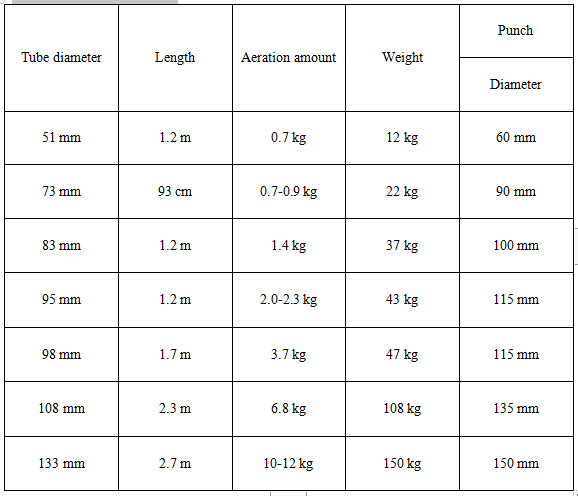

Equipment configuration see attached table 2

Schedule 2 Equipment Configuration Table

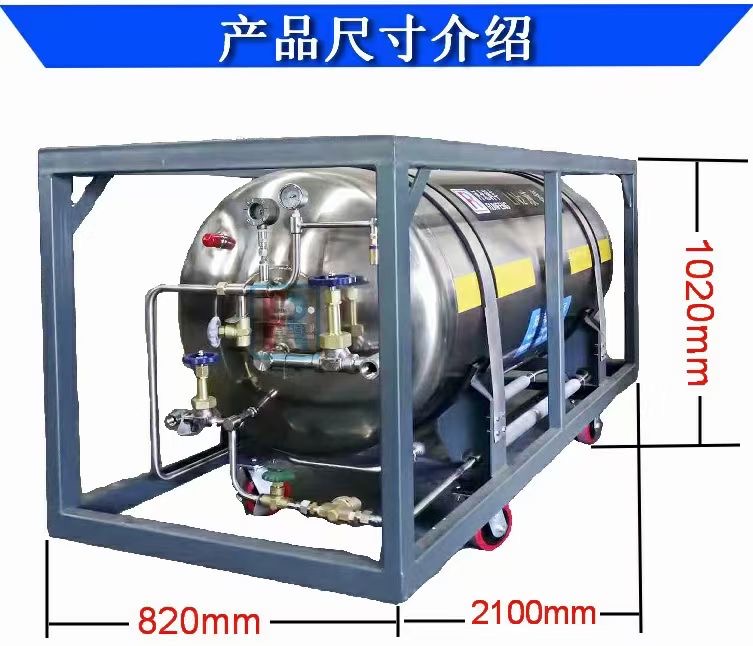

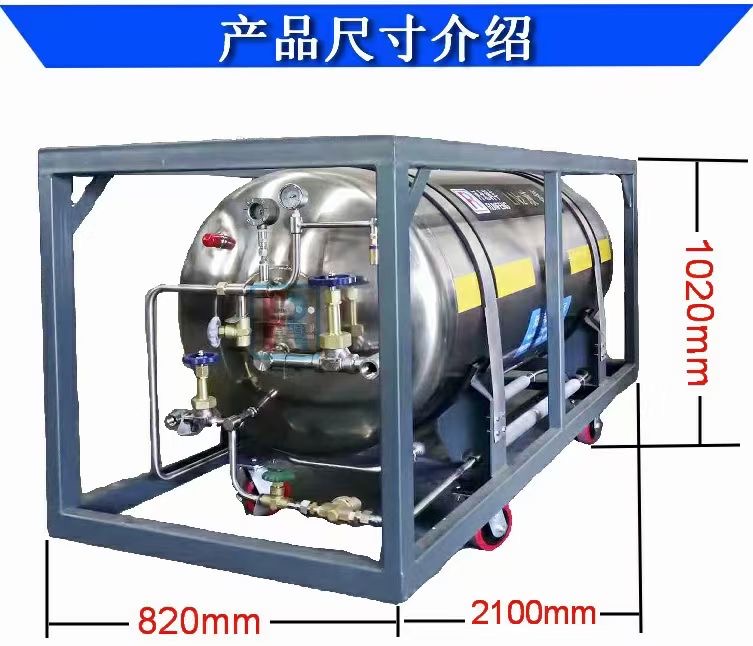

1 Ground operation room and equipment

The equipment in the ground operation room is: carbon dioxide liquid storage tank, filling machine, filling station, disassembling machine, etc., as shown in Figure 2.

Liquid storage tank Filling machine Filling stand Disassembly machine Display stand

Figure 2 Schematic diagram of the ground operation workshop equipment

The function of the operation room is to fill the expansion tube, store the expansion tube, issue the expansion tube, and repair the related equipment.

2 Construction site equipment

The equipment is mainly an expansion tube, an igniter, and a 150 type pneumatic rock drilling machine.

1) Expansion tube

The expansion tube(rock splitting tube) is one of the core equipment of the Expansion cracking rock technology of carbon dioxide, and the structure is as shown in the Fig 3. It consists of an expansion tube, a filling head, a moving head, and the like. Made of extra-strength special steel and specially treated, it has extremely high strength and toughness.

Figure 3 Schematic diagram of carbon dioxide expansion tube structure

1.Filling head-2.Heater-3.Liquid storage tube-4.Seal ring-5.Blasting piece-6.Moving head

3) Igniter

Figure 4 Digital carbon dioxide igniter

As shown in Figure 4, the digital carbon dioxide igniter is the core device for igniting the activator in the expansion tube.

Ⅱ) This operation step (taking 133 diameter circulation expansion tube as an example)

1. Overall operation steps (taking the 133 type expansion tube as an example)

The overall steps are:

Assembling in the ground operation room - filling the gas-transporting the vehicle to the construction site-ignition-recycling the cracking pipe-transporting to the ground workshop-disassembly cleaning-reassembly

2 Ground operation steps

1) Preparation before filling the CO2 expansion tube:

①It is necessary to supply 380V/220V AC to the filling machine and pneumatic disassembly machine.

②The liquid storage tank has enough liquid carbon dioxide.

③Expansion tube and corresponding consumables (activator, rupture disc, gasket).

④Million meters, pliers, wrenches, hex and other tools.

2) Assembly

a. Place the shredded tube reservoir on the display rack, insert the wire into the main tube, and extend the hooked end from the end of the main lettering. The wire is then hooked to the wire of the activator device and the wire is pulled to extend the wire from the other end of the expansion tube.

b. Attach the cracking tube to the sealing ring, and then pull out the activator device

c. Tighten the moving head first, and then tighten the filling valve until it stops.

d. Pneumatic tightening device tightens the pneumatic device clockwise, the inflation head, the moving head is screwed to the end.

e. Measure the resistance and the resistance is normal at 1-2 ohms.

3) Inflating

a. Align the filling port of the filling clip with the air inlet and clamp it, and open the filling valve with an Allen key. Then open the ball valve corresponding to the expansion tube to fill the liquid.

b. Deflating: Before the first work every day, you need to deflate and empty the entire pipe. First open the inlet ball valve and the outlet ball valve on the filling station. Then press the bleed button until the outlet ball valve ejects continuous white gas and closes the outlet ball valve.

c. Filling: After closing the outlet ball valve, press the boost button and the machine will stop automatically when the expansion tube is full. After the machine stops, close the filling valve of the cracking tube with an Allen key, then close the inlet ball valve, and then open the outlet ball valve to moving excess gas.

3. Expansion rock operation steps

1) Equipment transportation

The expansion tube is 2.7 m long and has an outer diameter of 133 mm. The mass of liquid carbon dioxide is about 150 Kg. The expansion tube is made of high-quality imported steel. It is durable and can be reused for more than 8,000 times. Except for connecting the circuit to start the expansion cracking, the bump, impact and high temperature will not damage the device.

(2) After the expansion pipe is filled with liquid carbon dioxide on the ground, the mine arranges the personnel to transport the mine car to the construction site in advance.

(3) The expansion tube that cannot be carried out or the endless test must be recycled in time and kept in a safe place.

2) Punch

Select the type of drilling rig: hard rock selection YGZ150 rock drilling machine According to the construction technical measures, the eye-catching requirements are required.

3) Connection

①Connect the DC plug of the fluid-filled expansion tube.

②Use a multimeter to measure the resistance at both ends. If the resistance should be around 2 ohms, the resistance is too large and the resistance is 0, which are both unqualified

③Use sand to seal the hole.

4) Expansion cracking rock

Punch: 133 model expansion tube requires the hole of 150 mm and depth of hole is 4-8 m.

5) Recycling

①Transfer the recovered expansion tube to the operation room with the mine car, place the expansion tube on the jaw of the disassembly machine, and insert one end of the filling valve into the disassembly head. Then turn the emergency stop button clockwise and press the start button to start the changer.

②Repeat steps

③Clean the residue inside the expansion tube for the next use.

V. Expansion cracking rock technology of carbon dioxide plan

Expansion cracking rock technology of carbon dioxide can be used in all locations where rock breakage and dredging are required.

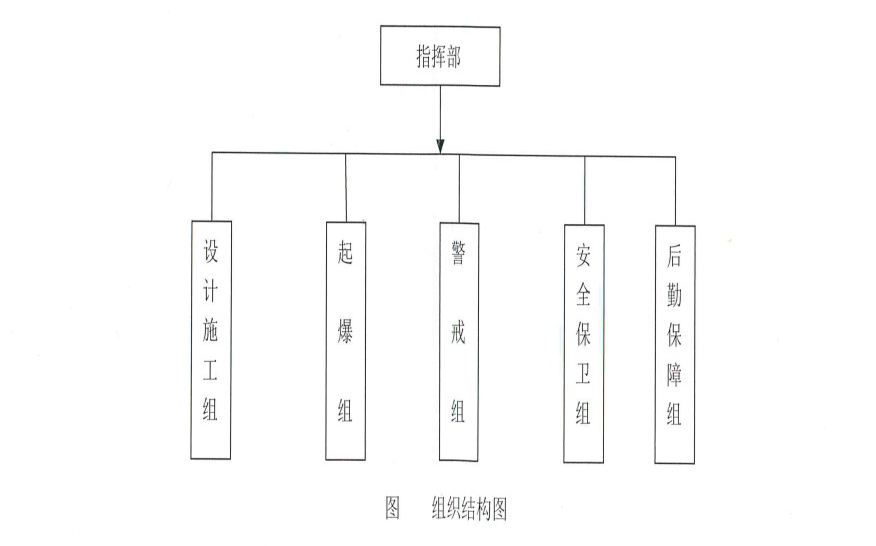

Ⅵ.Analysis of labor organization and production efficiency

Ⅰ) Labor organization

The ground work workshop has 2-3 people in one class, 2-3 people in the field, and 12 hours in each class.

Ⅱ) Analysis of production efficiency

150 models are filled with 10-12 kg per tube, 50 tubes need to be filled with 500-600 kg, and 499 L liquid storage tanks require 2 units. Fill 30-50 roots in 1 hour, 720-1200 tubes in 24 hours.

Transportation: When transporting on duty, the distance is long, and the expansion tube needed for transportation in one class is advanced.

Punching: The number of blastholes required is generally about one-third less than that of explosives. Therefore, it is possible to reduce the slowing of the drilling speed due to the enlargement of the blasthole aperture.

Down tube: Each drill eyes down tube takes 2 minutes.

Seal the holes: Each blasthole takes 1 minute.

Fixing: Seal each expansion tube with guar stones, and it takes 3 minutes for each expansion. The progress of the project is expected to be 4 times for each class of 12 hours of expansion, 3 hours for each expansion, and 10,000 T for each expansion. The construction can be expanded by 20,000 T per day. The total shared tube volume is 150 tubes.

VII. Construction safety, precautions and safety Technical measures

In the implementation process of carbon dioxide expansion rock technology, all construction workers must strictly abide by the Safety Regulations and all safety construction measures, and also need to implement this safety technical measure.

Ⅰ) Precautions

1) Equipment storage

(1) In the ground operation room, the person is responsible for the operation, and the unrelated personnel are prohibited from operating the equipment.

(2) The ground operation room is well ventilated and cool. When the cylinder is found to have corrosion, damage, cracks and other defects, report it to the test personnel and arrange for replacement.

2) Filling the expansion tube with carbon dioxide

(1) Fill in one shift in advance, so that it can be used as needed, and not stored for a long time.

(2) Before filling, unrelated personnel leave the warehouse, and the test personnel check the performance of the air compressor and the liquid injection pump to ensure that the carbon dioxide is filled when the device is normal.

(3) The operator needs to operate with gloves to prevent frostbite.

(4) During the filling process, strictly follow the Operation Manual. If there is a leak, stop it in time and check the fault.

(5) Check the expansion pipe before and after filling, verify whether there is air leakage in the liquid carbon dioxide; conduct the continuity test on the line to ensure the line is normal;

Ⅱ) Safety technical measures

1) Before the operation, train all relevant personnel and carry out simulation tests of various operations on the ground to ensure that everyone is proficient in correct operation.

2) The most dangerous thing in the ground floor workshop is that carbon dioxide is ejected, which may stab people or frostbite people. Therefore, be sure not to stay away from the vents.

3) Drilling construction shall be carried out in strict accordance with the construction of the implementation plan and related safety technical measures.

4) The sealing effect is directly related to the expansion effect. Therefore, before expanding the rock, the blasthole sealing must be checked and made true.

5) The igniter is operated, preferably by the Commissioner.

6) Check the igniter again before expanding the cracked rock. If it fails, it will not ignite.

8) Safe ignition position, in accordance with the execution of explosive blasting.

9) The scope of withdrawal shall be in accordance with the execution of explosives.

10) The three-person chain and so on shall be implemented in accordance with the relevant explosives blasting regulations.

11) The parts not covered by the safety measures are strictly implemented in accordance with the relevant regulations of the mine.

FAQ:

1.What is a CO2 rock demolition system?

Answer: A CO2 rock demolition system, is a specialized equipment used to break and demolish rocks or concrete structures using carbon dioxide gas as a non-explosive method.

2.How does a CO2 rock demolition system work?

Answer: The CO2 rock demolition system utilizes carbon dioxide gas, injected into pre-drilled holes in the rock or concrete, to create high-pressure micro-cracks, leading to controlled fragmentation and easy removal.

3.What are the advantages of using a CO2 rock demolition system?

Answer: The advantages of a CO2 rock demolition system include its non-explosive nature, reduced vibration, minimal noise, enhanced safety, precision in rock splitting, and environmental friendliness.