- Gaea

- 中国

- 5-25天

All of our tails are made of high-quality steel and then processed by cnc and carburized to ensure that they have excellent toughness and sufficient strength to meet the stringent requirements. Operating environment. In addition, according to the requirements, all the solder tails can be processed into male or female threads

T45 Shank Adapter Drill Shank Adapter

Related reports:

What are the classifications and styles of shank adapter;

T45 Drill shank adapter introduction:

The shank adapter, also known as a "shank adaptor," is an essential component of hydraulic rock drills, specifically designed for threaded applications such as the T45. At our company, we prioritize high-quality craftsmanship, employing heat treatment processes to ensure superior product quality. Throughout this introduction, the terms "shank adapter" and "Shank Adaptor" will be frequently used to emphasize the significance of this component.

To begin with, we carefully select premium alloy steel as the raw material for the shank adapter. Following this, the entire shank adapter undergoes a carburizing treatment, enhancing its strength and durability. We utilize specialized CNC machining equipment and follow precise processing techniques to guarantee the quality of the tail section, internal water holes, and side water holes. The shank adapter is uniformly heat-treated, employing precision instruments for accurate straightening, resulting in a straight and robust product resistant to vibrations.

The primary function of the shank adapter is to transfer energy between the drilling rig and the drill rod. One end is connected to the drilling rig, while the other end is connected to the drill rod. This enables the transmission of energy from the drilling rig to the drill bit, ultimately facilitating the drilling process. When transmitting the impact power of the hydraulic rock drill, the shank adapter must withstand high levels of impact and torsional stress. Therefore, shank adapters for hydraulic rock drills undergo carburizing hardening treatment to improve the fatigue strength, rigidity, and wear resistance of the impact face, keyway, threaded portion, and the shank adapter's body.

Moreover, strict control is exercised over the straightness of the hydraulic rock drill shank adapter. After undergoing heat treatment, the shank adapter is subjected to a straightening process to ensure it meets the required specifications.

By utilizing advanced techniques, high-quality materials, and stringent quality control measures, our shank adapters are engineered to deliver optimal performance and durability in hydraulic rock drilling applications.

Gaea produce supporting tails for most rock drills currently on the market. All of our tails are made of high-quality steel and then processed by cnc and carburized to ensure that they have excellent toughness and sufficient strength to meet the stringent requirements. Operating environment. In addition, according to the requirements, all the solder tails can be processed into male or female threads.

Male threads are generally suitable for sedimentary rock, tunneling and other extended applications. When drilling space and total feed length are limited and important, female threaded shanks are used, such as underground ceiling anchoring.

The main role of the bit is to transfer torque, propulsion, impact and flushing medium to the drill pipe and bit.

Our brazing tails are designed to withstand the high impact of modern rock drills. They are made of special steel materials and have undergone carburization to increase the surface hardness. Now we can provide about 300 different specifications of brazing tails to match Tras, Tom Rock, Sandvik, Furukawa, Montebello, Denver and other series of rock drills. We produce supporting tails for most rock drills currently on the market. All of our tails are made of high-quality steel and then processed by cnc and carburized to ensure that they have excellent toughness and sufficient strength to meet the stringent requirements. Operating environment. In addition, according to the requirements, all the solder tails can be processed into male or female threads. Male threads are generally suitable for sedimentary rock, tunneling and other extended applications. When drilling space and total feed length are limited and important, female threaded shanks are used, such as underground ceiling anchoring. The main role of the bit is to transfer torque, propulsion, impact and flushing medium to the drill pipe and bit. Our brazing tails are designed to withstand the high impact of modern rock drills. They are made of special steel materials and have undergone carburization to increase the surface hardness. Now we can provide about 300 different specifications of brazing tails to match Tras, Tom Rock, Sandvik, Furukawa, Montebello, Denver and other series of rock drills.

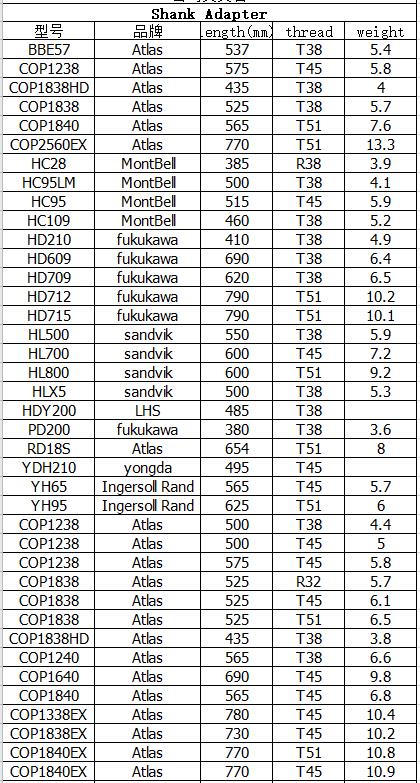

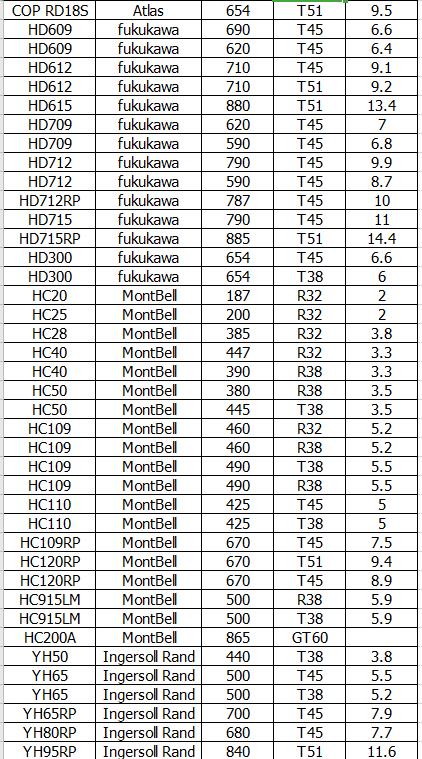

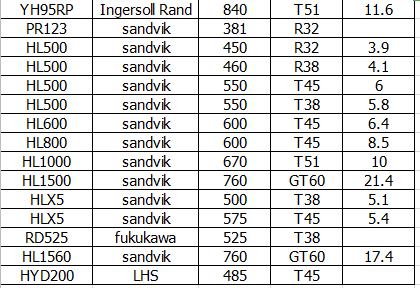

Code No.: COP1238/HC95/HL700/YDH210/YH65

Thread Type: T45

Length: 435-890mm

Rock Drill Manufacturer: FUKUKAWA/MontBell/sandvik/Ingersoll Rand

COP1238-T45-575:

HC95-T45-515:

HL700-T45-600:

YDH-T45-495:

YH65-T45-565:

Shank Adapter Packaging:

Specification: