- Gaea

- 中国

- 5-25天

Tapered drill bits connect tapered drill steel of rock drill for drilling holes

Q8 Tapered Button Bit Taper Button Bits Dth Hammer Bits

Related reports:

What are the advantages of the tapered button bit;

Precautions for the use of drill bits;

The Importance of Cross Bits in the Development of my country's Industrial Development;

Q8 Tapered Button Bit Taper Button Bits Dth Hammer Bits

Welcome to Liaoning Gaea, a leading manufacturer of high-quality drilling tools and equipment. Our Q8 Tapered Bits are among our flagship products, designed to deliver exceptional performance in various applications such as mining, quarrying, construction, and compatible with handheld rock drills. With our advanced hot-insertion manufacturing process, we ensure the finest quality and reliability of our tapered bits, enabling efficient and precise drilling operations.

Key Features:

Superior Quality: The Q8 Tapered Bits are manufactured using our state-of-the-art hot-insertion technique, which enhances their durability, strength, and overall quality. This process ensures that our bits are capable of withstanding rigorous mining and construction environments, providing long-lasting performance.

Tapered Design: Our Q8 bits feature a tapered design, allowing for efficient penetration and increased drilling speed. The gradual taper ensures improved hole accuracy and reduced deviation, making them highly suitable for precision drilling tasks in mining and quarrying operations.

Button Bit Configuration: The Q8 Tapered Bits are equipped with strategically placed button inserts. These carbide buttons are carefully selected for their exceptional hardness and wear resistance, enabling the bits to maintain optimal performance even in abrasive rock formations.

Applications:

Mining and Quarrying: The Q8 Tapered Bits are specifically designed to meet the demanding requirements of mining and quarrying operations. Their superior strength and durability ensure effective drilling in various geological conditions, including hard rock formations. These bits facilitate efficient extraction of minerals and resources while minimizing downtime.

Construction Industry: Our Q8 Tapered Bits find extensive application in the construction industry, where precision drilling is essential. They are ideal for tasks such as foundation drilling, tunneling, and site preparation. The tapered design enables accurate hole creation and smooth drilling progress, resulting in enhanced productivity and reduced costs.

Compatible with Handheld Rock Drills: The Q8 Tapered Bits are designed to be compatible with handheld rock drills, providing flexibility and ease of use in various scenarios. Whether you are working in tight spaces or remote locations, these bits ensure optimal drilling performance while maintaining operator comfort and safety.

Conclusion:

At Liaoning Gaea, we take pride in manufacturing high-quality drilling tools, and our Q8 Tapered Bits exemplify our commitment to excellence. With their superior quality, tapered design, and button bit configuration, these bits are perfectly suited for mining, quarrying, construction, and compatible with handheld rock drills. Experience the efficiency and reliability of Q8 Tapered Bits for your drilling operations, and witness the difference they make in achieving exceptional results. Contact us today to explore our complete range of drilling solutions.

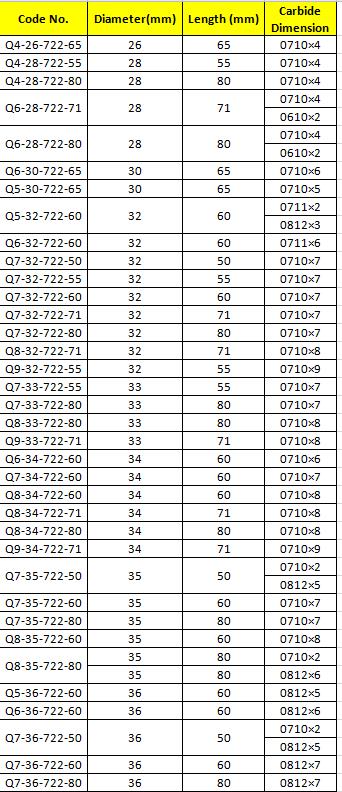

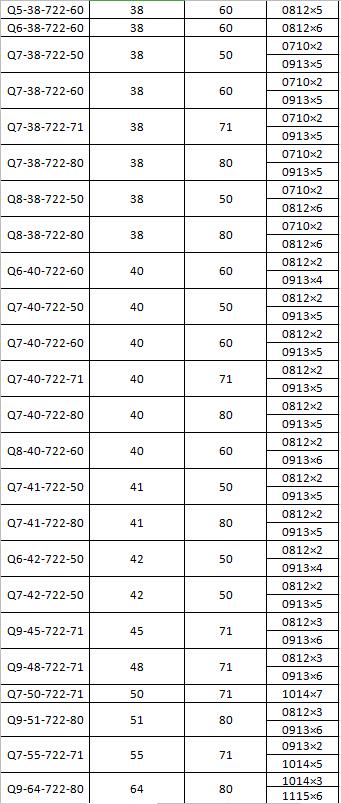

Product details:

1.Product Name:tungsten carbide drill bits

TypesTapered chisel bits, Tapered cross bits, Tapered button bits

2.Application:Tapered drill bits are used in granite and marble quarry, gold mine, railway, tunnel, etc. for drilling

3.Feature:Tapered drill bits connect tapered drill steel of rock drill for drilling holes

4.Material:High quality carbide and high quality steel

5.MOQ:No requirement for testing and trial order

6.Usage:Button bits has higher technology, much longer primary grinding time and higher drilling efficiency while comparing with taper chisel bits and taper cross bits, so that the button bit is popular among the users.

According to the tungsten carbide insert, button bits can be divided into the types of hemispherical button, conical button and parabolic button, etc.

Button bits with hemispherical button is for high bearing capacity and abrasive resistance while conical button and parabolic button are for high drilling speed and low abrasive resistance.

When drilling, adjust the parameters of impulse and rotary with the standards of no jamming, high drilling speed and no bend of tapered drill rods.

Check the rock drill bits after each drilling. If the buttons are seriously worn, replace the button bits timely to ensure the drilling speed. If it's possible, grind the button bit for reusing. Replace the button bits once the taper worn, otherwise the buttons would be seriously abraded and even jammed.

We can design and manufature according to your requirment of diameter, number air holes and carbide button shape.

How to use tapered button bit:

1. The taper of the drill bit and the drill rod should be effectively matched, and the mating length is ≥25mm. Please select an appropriate drill rod according to this principle.

2. The unloading device should be used to unload the drill, and it is strictly forbidden to hit with a hammer.

3. The cutting length of the drill bit must be controlled when the drill bit is used. When the drill bit is drilled slowly, and the obtuse angle width Δ≥2.5mm at both ends of the drill bit, it should be ground in time. Please use 46-60 when grinding. The line speed of silicon carbide grinding wheel is not less than 18 m/s.

The information you may like to know before order:

1.Method of payment:T/T(Telegraphic Transfer)or Western Union or L/C at sight.

2.Handing time for an order:Based on order quantity,normally it takes 25 days for production.only 2 or 3 days if we have stock on your request size.

3.Shipping way:Sample order,we suggest courier express like DHL/UPS/TNT by air.Bulk order we suggest by sea or by air.

4.Quality control:We have our own experienced QC,there will be strict inspe