- Gaea

- 中国

- 5-25天

Five basic designs are avaliable: Convex, Flat front, Drop Center Bit, Concave, and Double Gauge Face.

DHD Bits Dth Hammer Button Bits DTH Drill Bits

Related reports:

Maintenance method of cemented carbide DTH hammer drill bit;

Drilling principle of down-the-hole drill bits;

Manufacturing Requirements for Large Diameter DTH Drill Bits;

DHD Bits Dth Hammer Button Bits DTH Drill Bits

The DHD series of DTH bits is a highly efficient and versatile range of drilling tools specifically designed for rock drilling applications. These DTH bits are engineered to deliver exceptional performance and durability in various drilling projects, including mining, construction, and geotechnical exploration.

The DHD DTH bits are meticulously crafted to handle challenging rock formations encountered in rock drilling operations. With their advanced design and high-quality construction, these bits offer superior penetration rates and extended bit life, making them ideal for demanding drilling environments.

Key features of the DHD series DTH bits include:

1.Robust Construction: Manufactured from premium-grade materials, the DHD DTH bits are built to withstand the rigors of rock drilling and provide long-lasting performance.

2.Optimal Cutting Structure: The bits are equipped with precision-engineered carbide buttons or inserts strategically positioned for maximum rock chipping and efficient cuttings removal.

3.Versatile Compatibility: The DHD series DTH bits are designed to be compatible with DHD series DTH hammers, ensuring efficient energy transfer and optimal drilling performance.

4.Wide Range of Applications: The DHD DTH bits are suitable for various rock drilling applications, including mining, construction, and geotechnical projects. They excel in drilling through different rock formations, including hard and abrasive rock types.

In mining operations, the DHD DTH bits are highly effective in blast hole drilling, ore extraction, and rock reinforcement. Their superior rock penetration capabilities and durable construction enable efficient and productive drilling in challenging mining environments.

In construction projects, the DHD DTH bits play a vital role in foundation drilling, anchor hole drilling, and tunneling applications. These bits are engineered to withstand the demands of construction sites and ensure precise and efficient drilling results.

In geotechnical exploration, the DHD DTH bits are instrumental in sampling and site investigation drilling. Their ability to penetrate various rock formations with ease allows for accurate assessment and analysis of subsurface conditions.

The DHD series DTH bits, when paired with DHD series DTH hammers, form a highly efficient drilling system that optimizes productivity and ensures superior drilling performance in rock drilling operations.

Our DTH Bit can be suitable for many types of DTH Hammer, such as XL, Mission, COP, IR, Mach, Demag, SD, Bulroc, Halco Mach, Digger etc.

Five basic designs are avaliable: Convex, Flat front, Drop Center Bit, Concave, and Double Gauge Face.

These are designed for specific applications for all rock types, hardness's and conditions.

High Quality of Numa100-400mm Concave Dome Big Hole DTH Bit

Non shank and Carbide broken,

High fast penetration rate

Maximum hole deviation control,

Soft rock like sand stone, drilling life 1500 meter,

Hard rock like granite, drilling life 1000 meter,

High abrarsive like lime stone drilling life 600meter

Dome buttons as gauge buttons of DTH bits suitable for very abrasive and very hard formations,

Parabolic ( semi-ballistic buttons ) as gauge buttons and front buttons of DTH bits , suitable for medium abrasive and hard formation,

Ballistic button as front buttons of DTH bits, suitable for medium abrasive and medium hard formation,

Gaea offers a comprehensive range of high performance DTH hammers, DTH hammer bits, and accessories for use in the mining, construction, geothermal, and rotary drilling industries.

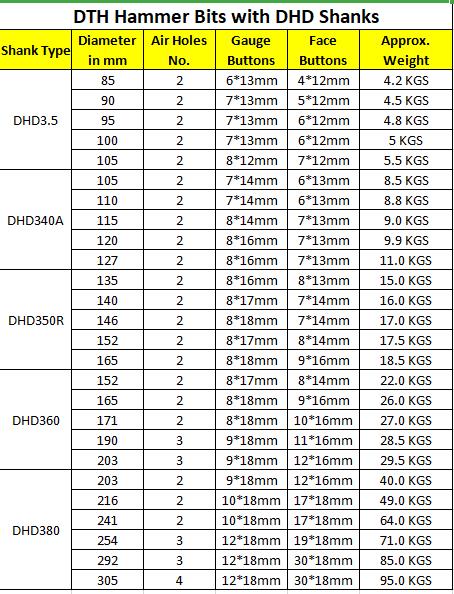

DTH hammer bits are available in sizes from 2" to 36", with all shanks, multiple head/face designs, and with a variety of tungsten carbide button styles to suit a wide variety of drilling conditions.

DTH accessories, including hammer oil andlube, grinding and sharpening tools, adapter, subs, shock absorbers, and more, are available to complement our DTH product offering.

Gaea manufacturer is equiped with elecro-hydraulic forging machine, metal processing line, heat treatment line, numerical control machines, which compose a complete production liine, and CNC machines are largely used in the whole manufacturiing process to insure every critical control point of quality.

· Code No.: DHD340-115

· Diameter: 115mm

· Air Holes: 2

· Gauge Buttons: 8*14mm

· Front Buttons: 7*13mm

· Carbide Design: Dome, Ballistic

· Face Design: Flat

· Shank Type: DHD