The difference between threaded drill bits and tapered drill bits and their application scenarios

In the field of rock drilling and exploration, threaded drill bits (Thread Bit) and tapered drill bits (Taper Bit) are two important types of drill bits, each with unique design features and application scenarios. Below we will introduce the difference between these two drill bits and their application scenarios in detail.

Taper drill bit: 1. There is no thread inside. 2. It is usually used to drill softer rock layers and is used with a tapered drill. 3. It is suitable for drilling operations that require high-precision positioning, such as geological exploration and light drilling operations. 4. The trousers are relatively short 5. The overall size of the tapered drill bit is small, and the diameter range is generally between 28-42 mm.

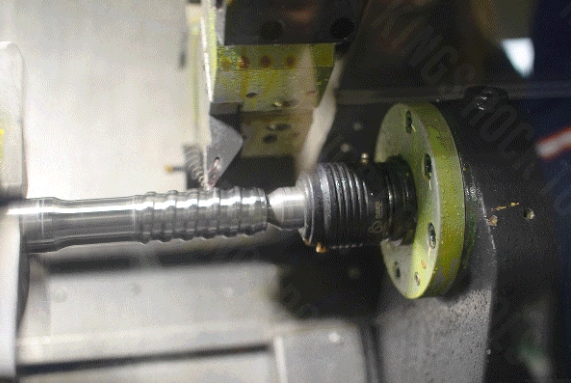

Threaded drill bit:

1. There are threads inside. 2. It is usually used to drill harder rock layers and is used with threaded drill rods. 3. It is suitable for occasions that require high-intensity drilling, such as mining and construction. 4. The body is relatively long. 5. The diameter range of threaded drill bits is generally between 33-127 cm. The easiest way to tell the difference between these two drill bits is whether they have threads or not! !

Application scenarios of tapered drill bits: 1. Geological exploration: used for shallow drilling in geological exploration. 2. Light drilling: suitable for drilling operations with handheld and air-legged light rock drills. 3. Soft rock formations: suitable for drilling softer rock formations, such as shale and mudstone. Application scenarios of threaded drill bits: 1. Hard rock formations: suitable for drilling harder rock formations, such as limestone and granite. 2. Heavy drilling: suitable for drilling operations performed by heavy drilling machines. 3. Mining: used for drilling and blasting operations in mining. 4. Construction: used for drilling holes in foundation engineering in construction.

Usage: Threaded drill bits are usually used with threaded drill rods, which are fixed by screwing them counterclockwise. The overall size of threaded drill bits is larger, and the diameter range is generally between 33-127 mm, so they are generally longer. Threaded drill bits are mostly used in hydraulic rock drills and are suitable for occasions where high-intensity drilling is required. Tapered drill bits are usually used with tapered rods. Commonly used tapered drill rods are 7 degrees, 11 degrees, 12 degrees, etc.

Summary: Threaded drill bits are suitable for drilling harder rock layers, while tapered drill bits are suitable for drilling softer rock layers. Choosing the right tool depends on specific application requirements, such as rock hardness, required drilling accuracy, and the type of drilling equipment. In actual operation, the proper selection of tools can significantly improve drilling efficiency and processing quality.