Popularization of down-the-hole drilling tool knowledge and summary of detailed steps for daily storage

Size selection of down-the-hole hammer, drill bits, and drill pipes

The size of the down-the-hole hammer mainly depends on the drill hole diameter and rock type. For blasting holes, the hole diameter range of down-the-hole drilling into rock is from 89mm to 252mm. For holes smaller than 89mm, you can choose top

Hammer type, a multi-purpose down-the-hole drill with a hole diameter greater than 252mm, a rotary pneumatic impact drilling method. Generally speaking, the minimum hole diameter of a drill bit that can be used by a down-the-hole hammer is its nominal drilling diameter, which means that the minimum hole diameter that a 4-inch hammer can be used for is a 4-inch hole diameter. Generally speaking, in this case, there is enough annular space between the hammer and the hole wall, and between the drill pipe and the hole wall for slag discharge. The empirical algorithm for the maximum drill bit size is the hammer size plus 1 inch. For example, the maximum drill bit size for a 4-inch hammer is 5 inches.

The closer the outer diameter of the drill pipe to the outer diameter of the hammer, the better, which can ensure better slag discharge and excavation rigidity, and also reduce the possibility of drill sticking.

In terms of drill pipe processing technology, the surface finish and dimensional accuracy (wall thickness) of cold-drawn pipes are better than those of hot-rolled pipes. Good surface finish means that the surface of the steel pipe is not easy to peel, and the metal debris caused by peeling will reduce the service life of the drill pipe. In addition, it is recommended to use a new process of friction welding for the threaded and main connection parts of the drill pipe, which can increase the strength of the drill pipe. At the same time, the threaded part can be better heat treated separately to increase the reliability and strength of the thread and make connecting and unloading the rod smoother. , improve work efficiency and overall punching speed

How to choose the right down-the-hole drill bit

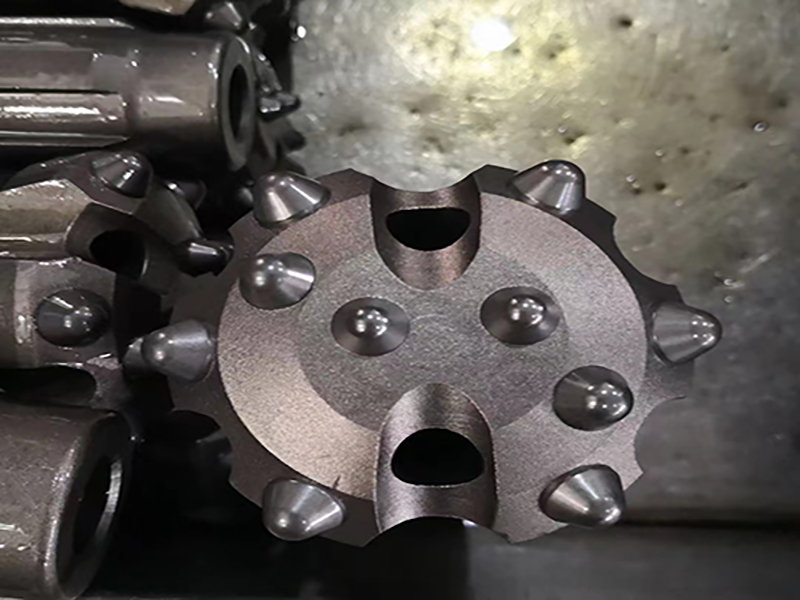

Let’s look at the drill bit again. The main body of the drill bit is usually machined from chromium-containing nickel alloy raw materials, and then heat-treated to a specified hardness so that the compressive stress on the surface has sufficient fatigue resistance. Then the carbide drill teeth (cone) are added. teeth, ball teeth, spring teeth).