In-hole filling of liquid CO2 Disposable rock blasting tube using operating procedures

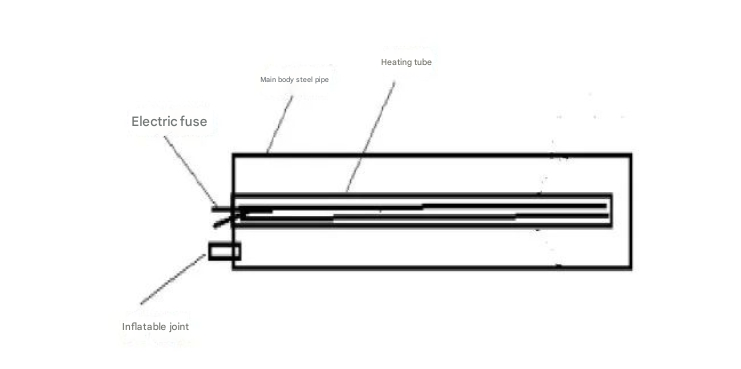

Structure diagram of disposable rock blasting tube for filling liquid CO2 in the hole Our company's disposable rock blasting tube for filling liquid CO2 in the hole adopts factory packaging inspection of the overall structure. All inspections are qualified before leaving the factory. There is no leakage or short circuit of the heating tube. It is safe and reliable to use. Its main structure is shown in the figure below:

1. Inflatable joint: used for inflation. Before burying the pipe, it is necessary to connect the inflation tube to extend according to the hole depth. The inflatable tube of our company's in-hole inflation rock blasting tube is equipped with an 8mm seamless fluid tube. The length of the inflation tube can be customized according to the customer's hole depth, and the connector is equipped. Customers can also prepare it by themselves. 2. Electric ignition foot line: connected to the detonation line, it must be short-circuited when not connected. 3. Main steel pipe: storage of liquid CO2. 4. Heating tube: used to heat liquid CO2.

2. Procedures and precautions for using liquid CO2 one-time rock blasting tubes

1. Drilling: The diameter of the Gaea 114 type in-hole gas tube is 140 mm, and the diameter of the Gaea 90-1 and Gaea 90-2 type in-hole gas tube is 110 mm. The drilling depth exceeds the step surface by no more than 0.2 meters. The blockage depth is not less than 2.0 meters, the resistance line distance is 1.5 meters to 2.5 meters, the hole spacing is 2 meters to 3 meters, the hard rock takes the smaller value, the soft rock takes the larger value, and the hole network parameters can be adjusted appropriately according to the effect after blasting.

2. Prepare the lower pipe. Use a 17-19 wrench to tighten the customized gas tube according to the hole depth to the gas joint, connect the appropriate length of the detonating wire to the electric ignition foot wire, and wrap the joint tightly with insulating tape for waterproof protection.

3. Lower the pipe. Two people work together. One person pulls the inflatable tube and the other person holds the detonating wire. Sink the fracture pipe to the bottom of the hole. Be careful not to break the detonating wire when lowering the pipe.

4. Fill. Use a fiber bag to fill the top of the pipe before filling to protect the line. Use leak-proof plugging or quick-drying cement to accelerate the solidification of the plugging material. It can be detonated after solidification for at least 2 hours. It can also be filled with rice stone. When filling, make sure that the cement or rice stone fills the gap between the fracture pipe wall and the hole wall and clamps the fracture pipe. Be careful not to break the detonating wire when filling.

5. Inflate. After the filling solidifies, tighten the female end of the quick-filling connector to the exposed end of the inflation tube, open the gas tank valve, open the inflation pipe valve to empty, close the inflation valve until white smoke comes out, insert the male end of the filling pipe into the female end of the inflation tube, open the inflation valve, start the filling machine to pressurize, fill to the set pressure (8MPa-9Mpa), the filling machine automatically starts and stops, close the inflation valve, empty the CO2 in the inflation tube, pull out the male end of the filling pipe, and complete the inflation of the single-hole inflation fracture tube. Insert the male end of the filling pipe into the female end of the next inflation tube and start the inflation of the next fracture tube.

6. After the inflation is completed, personnel and equipment are evacuated to a safe area. The general warning range is a radius of 100 meters from the explosion area, and it is appropriately enlarged according to the actual situation.

7. Network detonation. First, conduct the detonating wire of each fracturer, then network it, and detonate it with the detonator after conduction.

3. Treatment of Dull Shots

1. After knocking out the dud tube, you can use a hammer to remotely knock the connection between the main tube and the end cap, and exhaust the gas in the tube after it cracks to ensure safety; you can also directly press the cracked tube with a steel plate, unscrew the inflation tube with a wrench, use an awl to hold the one-way valve in the inflation head to deflate, or directly unscrew the inflation head to deflate.

2. For the dud tubes left in the open air, if the inflation head is deformed or squeezed off after being scratched by a breaker or rock, and it is impossible to deflate from the inflation head, use a small electric drilling gun, first press the dud tube with a steel plate, and then drill a hole in the center of the inflation head hole. It is also feasible to deflate directly after drilling through;

3. Dud tubes must be handled in time. It is strictly forbidden to move and remove the cracked tubes privately before the gas in the tubes is removed. It is strictly forbidden to handle without safety protection. The cracked tubes contain high-pressure gas, and they must not be lost to the scrap market. They must not be cut at high temperature by oxygen cutting or cutting, and must not be stolen. They must not be touched by unrelated personnel, which will cause safety hazards.