How to judge the quality of the drill rod

Related products Link:

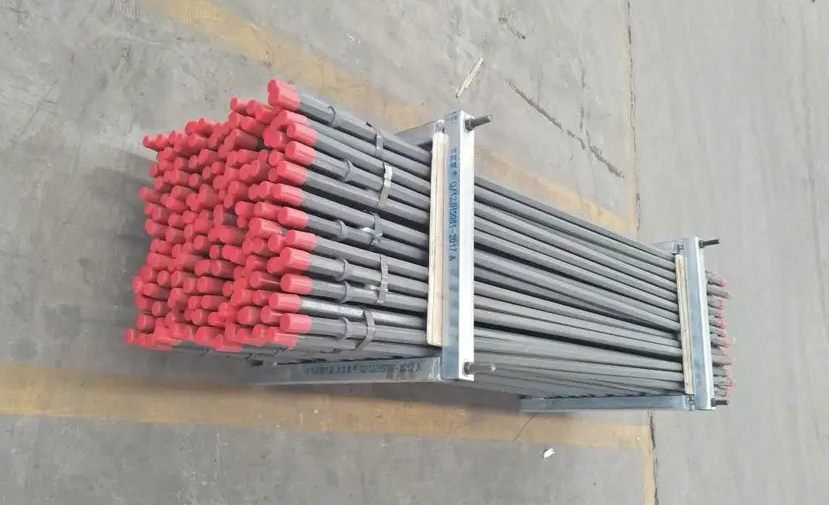

The drill rod is the tool used to connect the drill bit and the rock drilling in the tunnel engineering.

The drill rods generally used in mine tunnel engineering are hexagonal hollow steel and hollow round steel. The inner diameter of the hexagonal hollow steel is 22mm and 25mm, and the outer diameter of the hollow round steel is 32mm and 38mm. For making steel drills, the finished drills are forged according to a certain length and then directly installed on the drill bit. Then install the drill bit chisel.

The quality of the drill rod depends on many factors such as the steel type, the heat treatment process, the structural design of the drill rod, the transition between different sections, and even the size of the transition arc.

Among the above factors, the heat treatment of the drill rod is the main reason for the low life or premature failure of the drill rod. Correct selection of drill rod heat treatment process will effectively improve the quality and service life of drill rod products in my country, reduce consumption, and be beneficial to the improvement of comprehensive social benefits. It perfectly matches the in-line, cross and spherical rock drill bits of corresponding specifications. A large-scale, assembly line operation has been formed, and the quality of each process is strictly controlled, and substandard products are prevented from entering the next process. Due to the excellent product quality and stable performance, it is deeply trusted by the majority of users, and its product sales have been in the forefront of the domestic industry for many years.