How to determine the rotation speed of the drilling tool?

Each impact of the drill bit can only break a certain range of rock. When the rotation speed of the drilling tool is too high, a part of rock nodules that have not been crushed by the impact will inevitably be left between the secondary chiseling marks, which will increase the rotational resistance torque, increase the vibration of the drilling rig, and rapidly wear the hard alloy on the end face of the drill bit and in the radial direction. , not only reduces the drilling speed, but even causes drill pinching accidents; when the rotating speed is too low, repeated crushing may occur, the impact energy of the drill bit is not fully utilized, and the drilling speed is reduced.

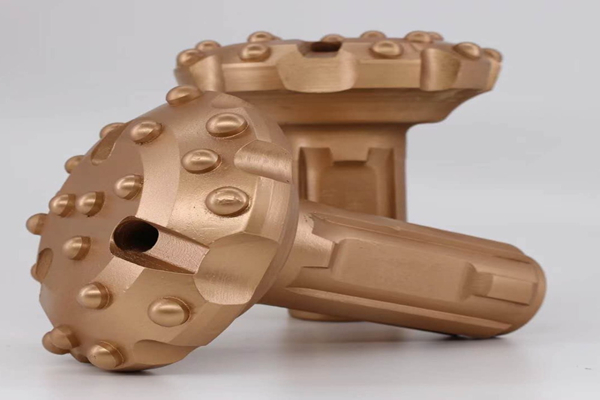

The optimal number of rotations of the drilling tool should be determined according to the maximum rotation angle of the largest fan-shaped area of the bottom of the hole that can be broken between two impacts of the drill bit. However, this reasonable rotation angle is related to factors such as drill diameter, rock physical and mechanical properties, impact energy, impact frequency, axial pressure, number and shape of drill bits, and wear degree of cemented carbide sheet (column).

Generally speaking, when the diameter of the drill hole is smaller, the hardness of the rock is lower, the impact energy is greater, the impact frequency is higher, the axial pressure is greater, the number of drill bits is more, and the carbide sheet (column) is sharper. The drill speed can be higher. On the contrary, the speed should be lower.