Down-the-hole drill bit damage problem treatment and service life

In recent years, my country's down-the-hole drill tools have developed rapidly. Due to its cost-effectiveness, they have been promoted and applied in more and more rock drilling projects. The number of companies involved in the drill steel drill tool industry is increasing. Due to the sharp increase in the amount of applications, some problems in the use of down-the-hole drill bits, such as broken teeth, tooth loss, block loss, fracture, wear, etc., have become increasingly prominent, and disputes between suppliers and users often occur. Among the damaged down-the-hole drill bits that users have filed claims against suppliers, some are caused by product quality problems, and some are caused by users' inability to use and improper use. More are caused by different measurement standards and understanding of the problem. In order to improve the quality of the drill bit, make the industry develop more healthily, and reduce disputes between suppliers and users, it is necessary to establish a standard that can be used as a reference among all suppliers, and at the same time, to enable suppliers and users to have a more objective measurement standard for the evaluation of the life and damage of down-the-hole drill bits. The (General Principles for Handling Down-the-hole Drill Bit Damage Problems) is specially formulated as a reference for the manufacture and sale of down-the-hole drill bits. The use of all parties to deal with the life and damage of down-the-hole drill bits will be implemented in future production, distribution and use.

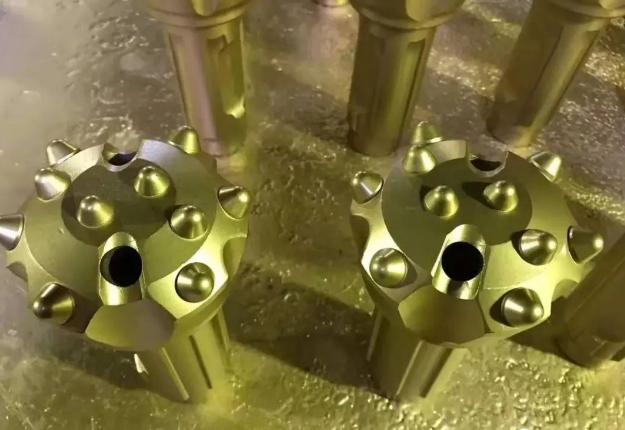

Service life of down-the-hole drill bit: Any machine or component has a certain service life and failure form. The drill bit reaches the specified service life when the following failure forms occur: 1. When the down-the-hole drill bit works in the case of rock hardness F>10: When the wear width of the drill bit edge tooth alloy reaches 60% of the edge tooth diameter, the drill bit is considered to have reached its service life. For example: when the drill bit edge tooth diameter is 14mm, when the edge tooth wear width H>~8.4mm (when the drill bit edge tooth alloy wear is uneven, H takes the maximum value), it is the service life. If it continues to be used, the alloy teeth will appear broken teeth, teeth will fall off, the drill body will fall off, the handle will break, and the rock drilling speed will decrease. 2. When the down-the-hole drill bit works in the case of rock hardness F≤10: a. When the impact depth B of the impact surface of the drill bit tail is ≥0.6mm or the wear amount of the spline width is ≥0.6mm, the drill bit is considered to have reached its service life. At this time, the wear amount of the drill bit alloy may not reach 60% of the edge tooth diameter, but the fatigue life of the drill bit body has been reached. If you continue to use it, the drill body will drop pieces, the shank will break, the alloy teeth will fall off, the teeth will be broken, etc. b. When the wear amount of the drill head diameter is ~>3mm or the abrasion amount of the drill top is ≥1mm, the drill is considered to have reached the end of its service life. If you continue to use it, the drill body will drop pieces, break, the alloy teeth will fall off, the teeth will be broken, etc.