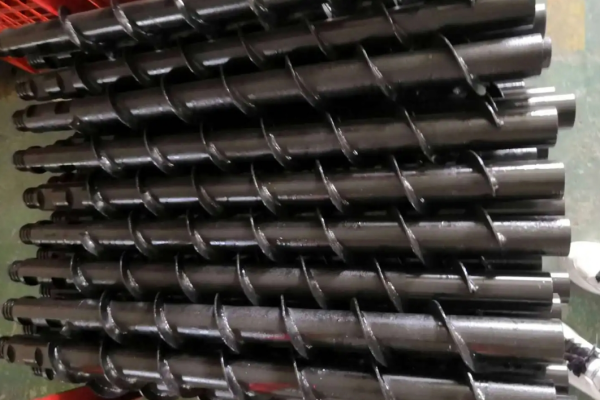

Correct cleaning method of rotary excavator drill pipe

When cleaning the drill pipe of a rotary excavator, you must first understand the cause of sedimentation at the bottom of the hole.

1. Remains between the bucket teeth of the rotary drilling rig and the bottom cover of the drill bucket.

2. The bottom cover is not closed tightly.

3. When drilling into mud, sand, and flow-plastic formations, the drilling slag in the drill bucket is seriously lost during lifting, and sometimes even all of it is lost in the borehole.

4. The soil cut by the outer edge of the drill bucket of the rotary drilling rig remains on the edge of the hole bottom because the bottom of the hole is flat and cannot enter the entrance of the cylinder.

5. The teeth of the drill bucket are arranged sparsely, and leakage between teeth is inevitable.

6. The drill bucket's return footage is too large, the load is too full, and the dirt is squeezed out from the drainage hole in the top cover.

Based on the characteristics of rotary drilling rig construction methods, we have developed two hole cleaning methods and achieved good results.

At the same time, we can also control the speed of soil sedimentation by changing the difference in specific gravity between soil and mud and increasing or decreasing the viscosity of mud. For example, if we want to reduce the sedimentation speed of soil, we should adapt to increasing the specific gravity and viscosity when preparing mud. On the contrary , we can reduce the specific gravity and viscosity to speed up the settling speed of rotary drilling rig soil.

What should we do if the sediment at the bottom of the hole cannot reach the standard? For this reason, we must clean the hole. Otherwise, the settlement of the top of the pile will be large and the bearing limit will be reduced. The commonly used methods for cleaning holes with rotary drilling rigs include the settlement method and the replacement method. The so-called settlement method is the ultimate After drilling, wait until the soil residue settles to the bottom of the hole before cleaning the hole. The replacement method is to clean the bottom of the hole immediately after the final hole, that is, use newly prepared mud to clean the hole in the hole before the soil residue has settled from the mud. A method of displacing mud outside the hole.

For forward and reverse circulation drilling, it is appropriate to use slurry replacement to clean holes, because it can use its own rotary drilling rig drill pipe to perform forward and reverse circulation slurry changes, while the drill pipe used for rotary drilling does not have the function of transporting circulating fluid. Using this method to clean the hole requires re-preparing the drill pipe and corresponding rotary drilling rig equipment, which is obviously not feasible. However, the sedimentation method commonly uses the conduit suction mud pump method, the air lift method, and the submersible mud pump method.

There are also some problems in the use of these methods, mainly the influence range of the slag suction port. When the hole diameter is 1.5 meters, if the position of the slag suction port cannot be moved or there is no tool stirring at the bottom of the hole, the drilling slag far away from the radius will be larger. Difficult to remove.