Basic knowledge of mine blasting!

1. According to the blasting safety regulations, how are mine blasting projects classified?

According to the blasting safety regulations, mine chamber blasting projects, large deep hole blasting projects, demolition blasting projects, and complex environment rock and soil blasting projects should be managed in a graded manner. The classification of various blasting projects is listed in the table below. Blasting projects of grades A, B, C, and D should be designed, constructed, and approved in accordance with the corresponding regulations.

2. What are the commonly used mining explosives?

Commonly used explosives refer to explosives used for excavation of various types of mine shaft and tunnel projects and for stripping and blasting rocks in mine mining. They are characterized by a wide source of raw materials, low cost, and low price, ensuring safety in manufacturing, transportation, storage, and use, that is, physical and chemical safety and stability.

3. How many commonly used detonation methods are there? What are the detonating equipment?

There are two methods to detonate mining explosives in explosive packs: one is to detonate industrial explosives through the explosion of detonators, and the other is to detonate industrial explosives with the energy generated by the explosion of detonating cords, and the detonating cords themselves need to be detonated with detonators first. According to the different ignition methods of detonators, the commonly used detonation methods can be divided into: electric detonation, non-electric detonation and wireless detonation. Among them, non-electric detonation methods include fire detonator detonation, detonating cord detonation and detonating tube detonation; wireless detonation methods include electromagnetic wave detonation and underwater sound wave detonation. The fire detonator detonation method uses the fuse to transmit the flame to ignite the fire detonator, also known as the fuse detonation method. The detonating tube detonator detonation method uses the detonating tube to transmit the shock wave to ignite the detonator, also known as the detonating tube detonation method. The use of detonating cord to detonate explosives is called the detonating cord detonation method.

At present, hybrid grids (including electric-plastic detonating cords, electric-detonating cord-plastic detonating cord networks, etc.) are often used in blasting projects to achieve the detonation of group explosive packages (chambers). Generally, detonating cords and plastic detonating cords are used in the branch network connecting the explosive packages (chambers), and the main network line uses electric detonation. The hybrid network is more flexible and safer to use.

Detonating equipment includes all ignition and detonation tools for detonating industrial explosives in blasting operations, which can be divided into two categories: detonating materials and transmission materials. Detonators are the main detonating materials in blasting projects. Fuse wires and detonating cords belong to transmission materials. Continuous detonating cords and detonating cords can play both the role of detonation and the role of transmission.

(1) Detonators

Detonators are energized by external energy and are detonating materials that can reliably cause the subsequent detonating materials or various industrial explosives to detonate. Detonators are of two types: fire detonators and electric detonators. Detonators that use fuses to detonate are called fire detonators, and detonators that use electricity to ignite and detonate are called electric detonators. Since there are gas and coal dust in coal mines, it is forbidden to use open flames for detonation in coal mines. Only electric detonators can be used.

(2) Detonating cord

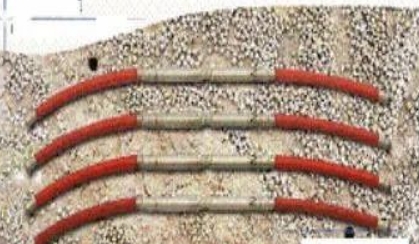

Detonating cord, also known as detonating wire, is a cord-shaped detonating material with auxiliary explosive as the core and cotton, linen, fiber, etc. as the covering material. It can transmit detonation waves. Detonating cord can be used to transmit detonation waves and directly detonate explosives or another detonating cord connected to it.

(3) Detonating cord

Detonating cord is a delayed detonating device specially used in conjunction with detonating cord. With the help of the micro-difference delayed detonation effect of the detonating cord, it can achieve micro-difference blasting together with the detonating cord.

(4) Detonating cord

Detonating cord is a non-electric detonating device that cannot directly detonate explosives. It can only transmit detonation waves to detonate detonators. The explosives are detonated by detonators. Detonating cords cannot be used in workplaces where there is a risk of gas or mine dust explosion.

4. How to check the detonation network?

The inspection of the detonation network is an important part of blasting safety. The inspection of the detonation network should be carried out by an inspection team composed of experienced blasters, and the inspection team should not be less than two people. The main contents of the inspection are as follows.

(1) The electric detonation network should be connected to the main line after the following inspections: whether the power switch is in good contact, whether the current passing capacity of the switch and the wire can meet the design requirements; whether the network resistance is stable and consistent with the design value; whether the network has grounded or rusted joints, short circuits or open circuits; when using a detonator for detonation, its detonation capacity should be tested.

(2) The detonation network of the detonating cord or detonating tube should be checked for: whether there is any missing connection, interruption or damage; whether there is any knot or loop; whether the branch corner meets the regulations; whether the detonator bundling meets the requirements; whether the line connection method is correct and whether the number of detonator sections meets the design; whether the network protection measures are reliable.

5. What are the blasting warning signals?

In order to ensure the safety of blasting operations and avoid the hazards caused by blasting, various blasting warning signals need to be issued during the blasting process. All kinds of signals should be clearly heard or seen by people in the blasting warning area and nearby personnel.

(1) Warning signal: After the signal is issued, the clearing work starts within the blasting warning area.

(2) Detonation signal: The detonation signal should be issued after confirming that all personnel and equipment have evacuated the blasting warning area, all guards are in place, and the conditions for safe detonation are met. After the detonation signal is issued, the person responsible for detonation is allowed to detonate.

(3) Release signal: After the safety waiting time, the inspector enters the blasting warning area to inspect and confirm safety before issuing the release signal. Before this, the sentry shall not be evacuated, and non-inspection personnel are not allowed to enter the blasting warning area.

6. How to carry out the actual operation of exposed blasting?

First, pack the weighed explosives in a plastic bag and make a flat round cake-shaped explosive package. Then put the explosive package in the center of the surface of the blasting body, place the detonator in the middle of the explosive package, and finally cover it with wet soil or water-containing sand (plastic bags filled with water can also be used) for detonation. The thickness of the covering body should be greater than the thickness of the cake.

If multiple explosive packages are detonated with a fuse, the first explosive package should be kept at a sufficient distance to prevent the explosion of the adjacent explosive package from dispersing the subsequent explosive.

7. What should be paid attention to when blasting the working face of a dead-end tunnel?

When blasting the working face of a dead-end tunnel, the working face and the fresh air flow tunnel should be kept unobstructed; after blasting, before the operating personnel enter the working face, they should be fully ventilated and the explosive pile should be sprayed with water.

8. When blasting the working face with gas and coal dust explosion hazards, what should be done before loading and blasting?

Before charging, the rock powder and coal ash in the blast-hole must be removed, because the rock powder in the blast-hole prevents the charge from reaching the bottom of the hole, and it is easy to leave the blast root after the explosion. If the coal powder in the blast-hole participates in the explosion reaction of the explosive, the original oxygen balance will be changed, and the CO in the explosion gas will increase. After the charging is completed, before detonation, the gas concentration in the wind flow in the blasting area must be detected. When the gas concentration in the wind flow within 20m near the blasting site reaches or exceeds 1%, blasting is prohibited.

9. What is the required length of the blast-hole filling in mine blasting work?

Different blasting holes have different plugging length requirements. The specific plugging length requirements for various blasting holes meet the following requirements:

(1) When the depth of the blasting hole is less than 0.6m, it should not be loaded or blasted; under special conditions, such as digging the bottom, brushing the side, and picking the top, when shallow blasting is required, safety measures should be formulated and the blasting hole depth can be less than 0.6m, but it should be filled with blasting mud;

(2) When the blasting hole depth is 0.6~1m, the sealing mud length should not be less than half of the blasting hole length;

(3) When the blasting hole depth exceeds 1m, the sealing mud length should not be less than 0.5m;

(4) When the blasting hole depth exceeds 2.5m, the sealing mud length should not be less than 1m;

(5) When smooth blasting, the surrounding smooth blasting holes should be sealed with blasting mud, and the sealing mud length should not be less than 0.3m;

(6) When there are two or more free faces on the working face, the minimum resistance line in the coal seam should not be less than 0.5m, and the minimum resistance line in the rock layer should not be less than 0.3m. When shallow-hole charge is used to blast large rocks, the minimum resistance line and the length of the sealing mud should not be less than 0.3m;

(7) When the blast-hole is sealed with water cannon mud, the remaining part of the blast-hole outside the water cannon mud should be sealed with clay cannon mud, and its length should not be less than 0.3m;

(8) It is strictly forbidden to blast blast-holes without sealing mud, insufficient sealing mud or unsound sealing mud.

10. What are the safety regulations for using electric detonators in underground coal mine blasting?

In the special blasting operation environment of coal mines, the following safety regulations should be followed when using electric detonators:

(1) Use coal mine permitted instantaneous electric detonators or coal mine permitted millisecond delay electric detonators;

(2) When using coal mine permitted millisecond electric detonators, the delay time from detonation to the last section should not exceed 130ms;

(3) Detonating cords or ordinary detonating cords should not be used;

(4) Fire detonators should not be used.