Analysis on the development direction of domestic down-the-hole drill bit hammer

Related products Link:

The development of modern brazing tools is not reflected in the substantial increase in the output of brazing steel, but mainly in the modernization and automation of the manufacturing process technology and equipment of brazing tools, the continuous improvement of the quality of brazing tools, and the research and development of new products.

Although air-operated rock drills are still being used in large numbers, hydraulic rock drilling equipment has the following advantages and has become the leading direction of the development of rock drilling equipment.

The equipment has good performance, high drilling efficiency and fast roadway excavation speed. If you use YYG-80A hydraulic rock drill to drill granite with a uniaxial compressive strength of 150-200MPa, the average drilling speed is 0.9~1.0m/min; drill magnets with a uniaxial compressive strength of 250~300MPa For quartzite, the average drilling speed is 0.81m/min. If the CGJ25-2Y medium and deep rock hole boring trolley is used, the average work efficiency is lm/2 shifts. Using this equipment in a lead-zinc mine, the highest single-shift footage is 5.4~6.0m.

The equipment has high energy utilization and low power consumption. According to statistics, air-driven rock drill energy is consumed by air compressors, compressed air pipes and rock drills, and its energy utilization rate is 0.084-0.112, while hydraulic rock drill energy is consumed by hydraulic systems, pipelines and hydraulic rock drills, and its energy utilization rate is 0.36 ~0.383. The energy utilization rate of the two differs by 3 to 4 times. In addition, hydraulic power costs are about 30% less than that of wind power.

Pollution of the working environment is small. The hydraulic rock drilling equipment has a high degree of mechanization and automation, which reduces the heavy manual labor of the operators and reduces labor consumption by 20%-30%. The noise is 15%-25% smaller than that of a wind-driven rock drill, and it eliminates the pollution of oil mist to the environment, improves the visibility of the working face, and creates conditions for remote control. Hydraulic rock drills are not only the main rock drilling equipment for underground mines, but also will gradually replace down-the-hole drills in medium and small open-pit mines. Therefore, it will be widely used in transportation, energy and other projects.

Since the first hydraulic press by the French company Momarbert in 1970, more than 20 companies in more than 10 countries have successively manufactured nearly 100 types of hydraulic chisel# machines of various types, and most of them are self-contained Into a system. The output has grown from 2,000 units in the 1980s to more than 10,000 units. At present, the products launched by various companies are generally the second, third, and even fourth-generation products. The structure of the equipment is continuously simplified, the hydraulic control technology is becoming more and more mature, and the life of the whole machine is continuously improved. The products of Swedish Sandvik Coromant company have not been disassembled for maintenance, and the drilling life of the whole machine has reached the level of 6000m.

In the early 1970s, China also began to develop hydraulic rock drilling equipment. Since the successful development of China’s first YYG-80A hydraulic rock drill and CGJ2Y full hydraulic rock drill rig in September 1980, the introduction of advanced foreign advanced hydraulic rock drilling technology and equipment has greatly promoted the development of China’s hydraulic rock drilling equipment process. By 1993, there were 15 manufacturers of hydraulic rock drills nationwide (11 of them also manufactured hydraulic rigs successfully developed and identified 25 types of hydraulic rock drills (including 5 types of imported technology, 4 types of imitations, 16 types of self-designed and manufactured) ), 16 manufacturing plants (11 of which manufacture hydraulic rock drills at the same time) manufacture 35 types of hydraulic rock drill rigs (including 15 types of imported technology). In order to meet the needs of China’s construction projects, in recent years, it has been from Sweden, Finland, France, Germany and Japan purchased more than 500 sets of more than 30 models of hydraulic rock drill rigs and more than 1,200 hydraulic rock drills. At present, hydraulic rock drills manufactured by imported technology have been mass-produced and put on the market, and their prices are lower than those in the international market. 1/4-1/3, the technical performance of the product has reached the level of similar foreign products. In our country, the popularization and application of hydraulic rock drilling equipment is the general trend.

Therefore, the development of medium and large cross-section susceptible rods used in heavy hydraulic rock drills and the development of hollow alloy carburized brazing steels have received widespread attention.

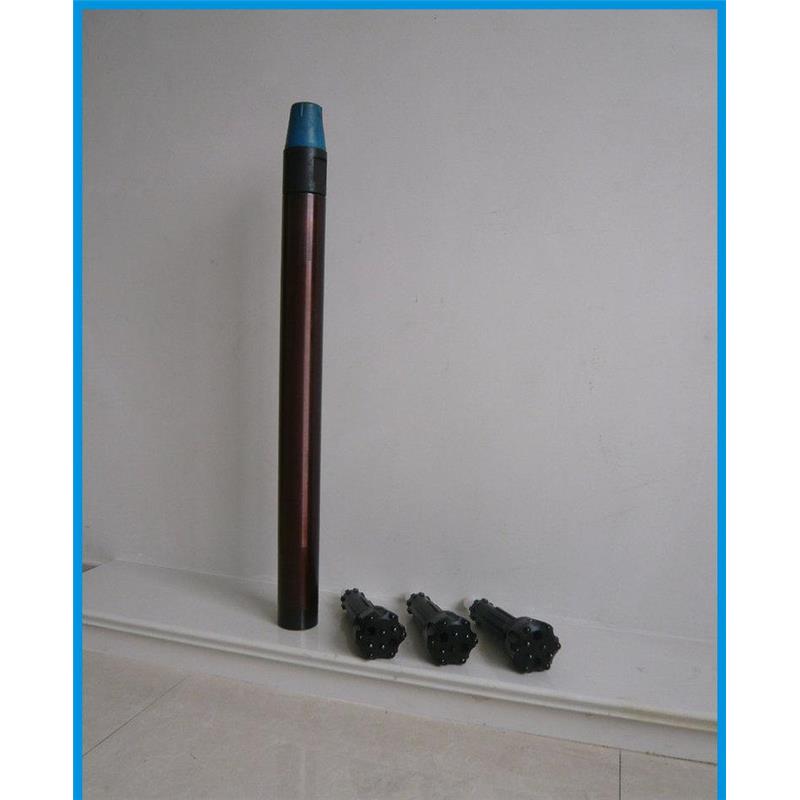

Because the column tooth bit does not need to be replaced and is not easy to stick, it has become a better supporting tool for the mechanized operation line of heavy rock drilling equipment with large shaft thrust and large impact power, and is the main way to improve the efficiency of expensive rock drilling rigs. means. In addition to roller cone bits and down-the-hole drill bits that have achieved cylindrical teeth at home and abroad, since the 1970s, various small-diameter carbide cylindrical bits have been used more and more. At present, in the international drilling tool market, the total sales volume of cemented carbide stub bits has surpassed that of the blade type bits, reaching more than 70% of the total sales volume of bits.