- Gaea

- 中国

- 5-25天

Discover Liaoning Gaea high-quality tungsten carbide inserts for efficient drilling. With various types available, we professionally select inserts based on different applications and drilling processes. Achieve optimal performance and productivity with our precision insert solutions. Trust in our durability and wear resistance to conquer tough drilling conditions. Partner with us for reliable and efficient drilling solutions.

Tricone Roller Bits 8.5-10inch

Related Reports:

The bearing characteristics of tricone bit and different between PDC bit;

What is the difference between a roller cone drill rig(tricone) and a down-the-hole drill rigs;

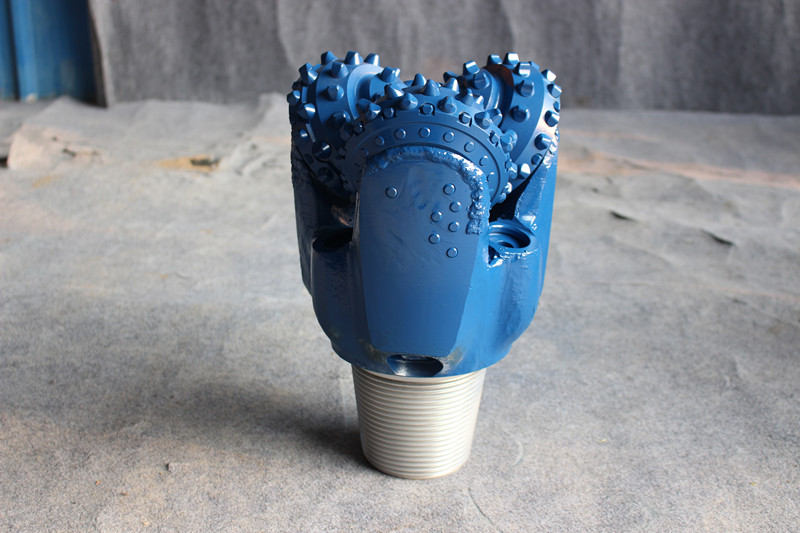

Introducing our exceptional Tricone Roller Bits, designed for superior performance in the drilling industry. At Liaoning Gaea, we specialize in providing high-quality Tricone Roller Bits with a diameter range of 8.5 to 10 inches.

Our Tricone Roller Bits are meticulously engineered to withstand the most challenging drilling conditions, ensuring optimal efficiency and productivity. With precision-crafted tungsten carbide inserts and robust steel tooth or tungsten carbide insert cones, these bits deliver exceptional durability and wear resistance.

The advanced design of our Tricone Roller Bits allows for efficient drilling through various formations, including soft, medium, and hard rock. Our expertise in selecting the ideal cutting structures and bearing designs ensures maximum drilling performance in diverse geological environments.

What sets us apart is our unwavering commitment to quality. Each Tricone Roller Bit undergoes rigorous testing and inspection to meet the highest industry standards. Our team of experienced engineers and technicians ensures that every bit we offer delivers outstanding performance and reliability.

By choosing Liaoning Gaea as your Tricone Roller Bits supplier, you benefit from our extensive knowledge and experience in the drilling industry. We understand the unique challenges faced by our customers and strive to provide tailored solutions to meet their specific needs.

Partnering with us means gaining access to a wide range of Tricone Roller Bits, designed for various drilling applications. Our comprehensive product lineup, combined with our technical expertise, allows us to offer customized solutions for your drilling projects.

Experience the difference of our Tricone Roller Bits and unleash the full potential of your drilling operations. Contact us today to learn more about our high-quality products and how we can contribute to your success.

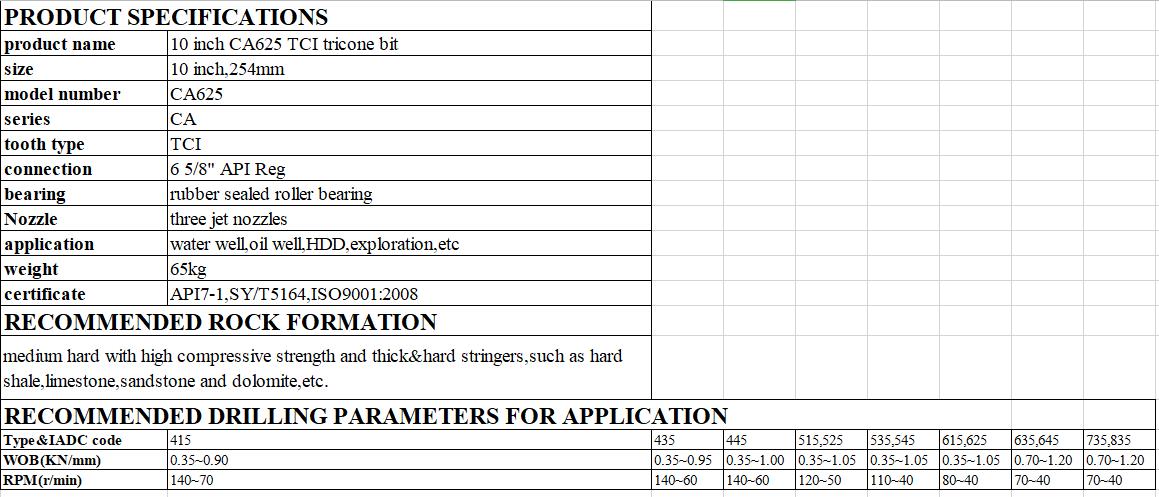

Specifications about our Gaea tricone bit

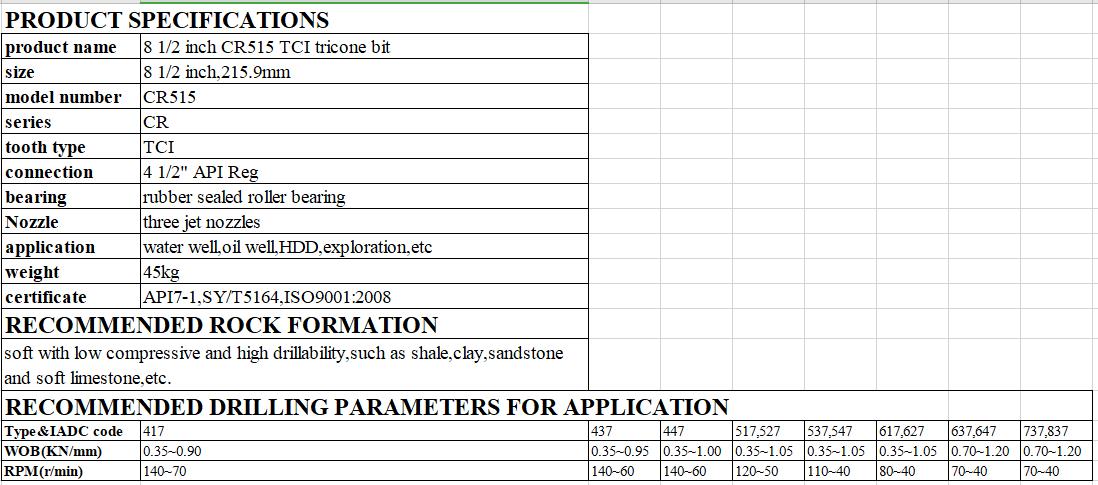

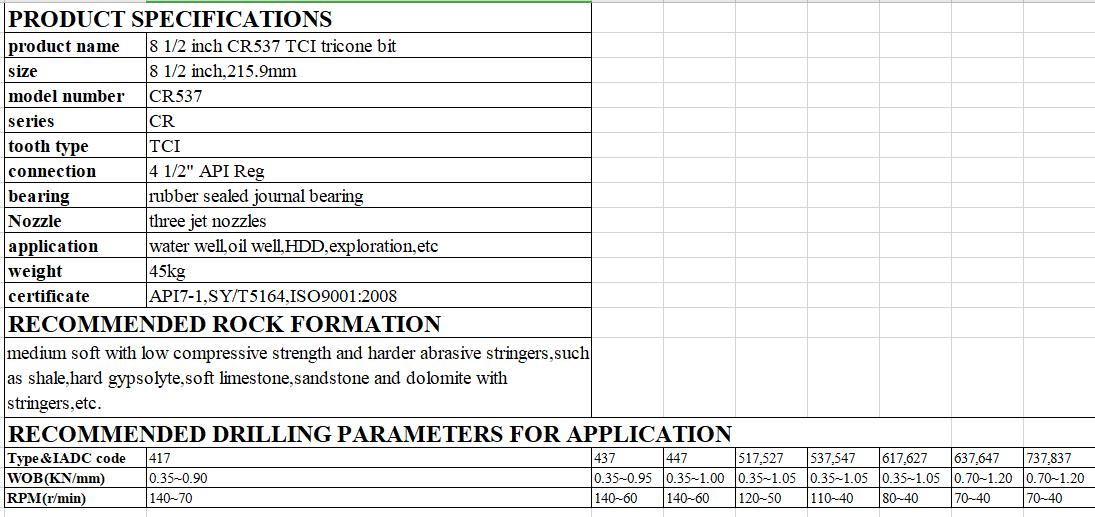

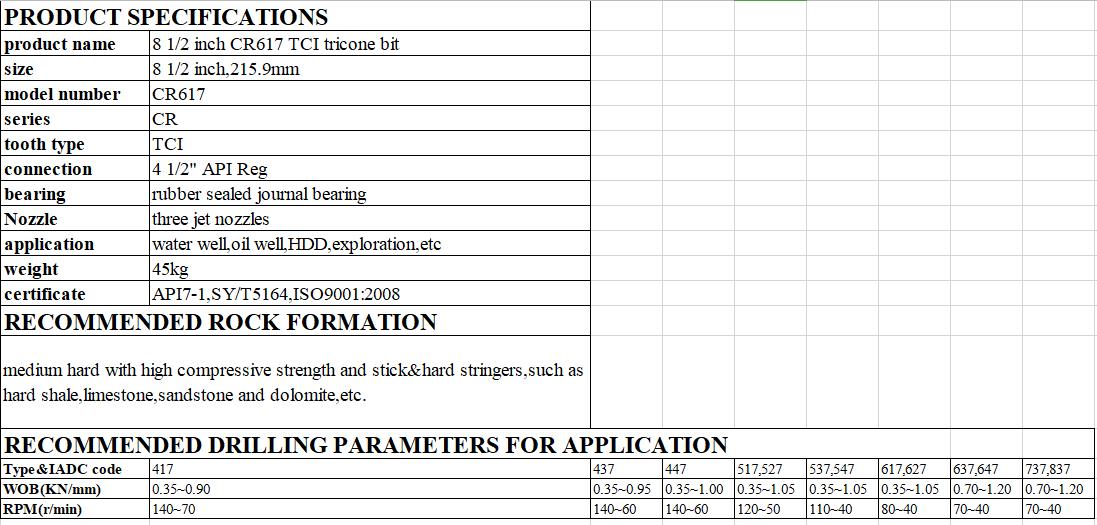

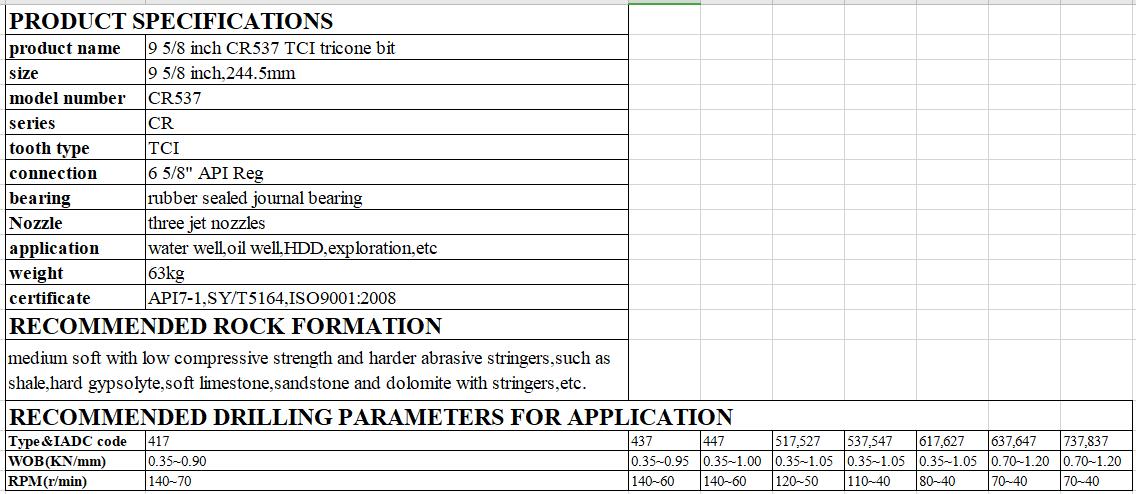

TCI bits

1, Soft formations(417, 437, 517, 537)

Features large chisel-shaped inserts to provide the highest penetration rate in the softest formations such as shales, clays, limestone and sands.

2, Soft to medium formations(617, 637)

Designed to drill effectively in formations such as hard limestone, dolomite, hard sands, and other formations with hard cherty.

3, Medium to hard formations(737)

For extremely hard formations such as chert, granite, flint, and taconite. Features short, closely-spaced inserts to ensure maximum penetration rate and wear resistance

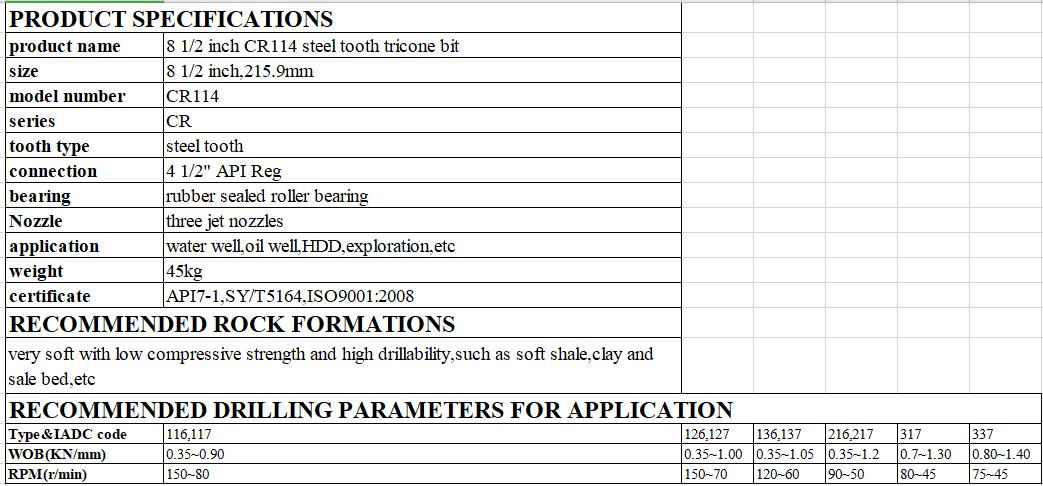

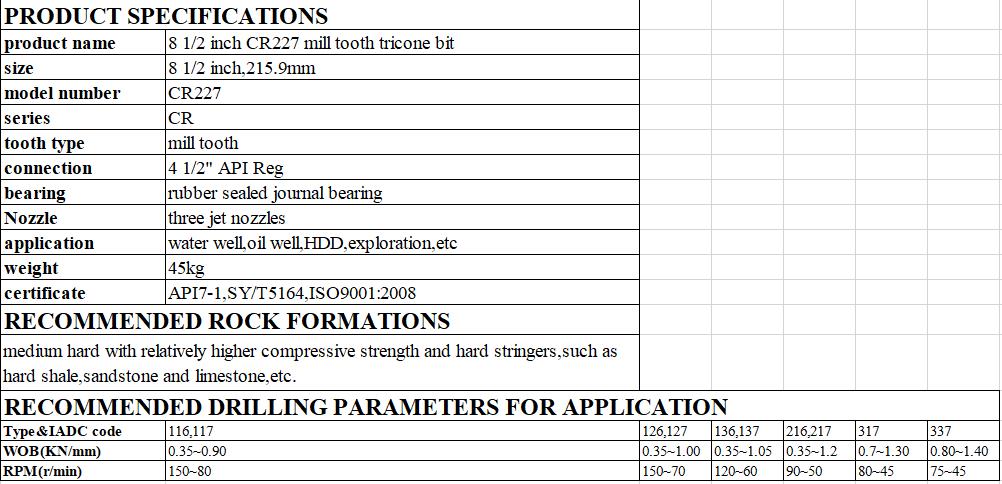

Milled tooth bits

1, Soft formations(114-117)

These bits are designed to drill the softest formations such as soft shales, red beds, and clays, with high durability and maximum penetration rates.

2, Soft to medium formations(121, 124, 126, 134, 136, 137)

These bits are designed to drill formations such as shales, medium soft limestone, Medium sandstone and other formations with intermittent hard streaks.

3, Medium to hard formations(213, 214, 215, 217)

These bits are designed to drill formations such as hard sandstone, dolomite, and broken formations with hard cherty streaks

Main features:

1. Cutting Structure of this type sealed and non-sealed TCI tricone bits:

The wear-resistance of teeth is enhanced with premium tungsten carbide hard facing on the tooth

Surfaces for steel tooth bit.

2. Gauge Structure of this type TCI tricone rock bits:

Multiple gauge protection with gauge trimmers on the heel and gauge inserts on the gauge surface of the cone, tungsten carbide inserts and hard facing on the shirttail increases gauge holding capability and bearing life.

3. Bearing Structure of this type TCI tricone rock bits:

High precision roller bearing with two thrust faces. Ball locks the cone. Thrust faces hard face with wear resistant alloy. Abrasion resistance and seizure resistance of the bearing are improved.

Air Cooling Roller Bearing Tricone Bit

----Cutting Structure

Tungsten Carbide Inserts: Various type high quality tungsten carbide inserts can be equipped on the bits, professional and scientific selection of the inserts as per the different application and drilling process to achieve high efficient drilling production.

----Gauge Structure

Multiple gauge protection with gauge inserts on the gauge surface of the cone, tungsten carbide inserts and hardfacing on the shirttail increases gauge holding capability.

----Bearing Structure

Air cooling roller bearing package. Balls lock the cone, which reduces the probability of cone-dropping to minimum.

---- IADC

Vary from 512--732 applicable for mining.

8.5Inch IADC114:

8.5Inch IADC515:

8.5Inch IADC227:

8.5Inch IADC537:

8.5Inch IADC617:

9 5/8Inch IADC537:

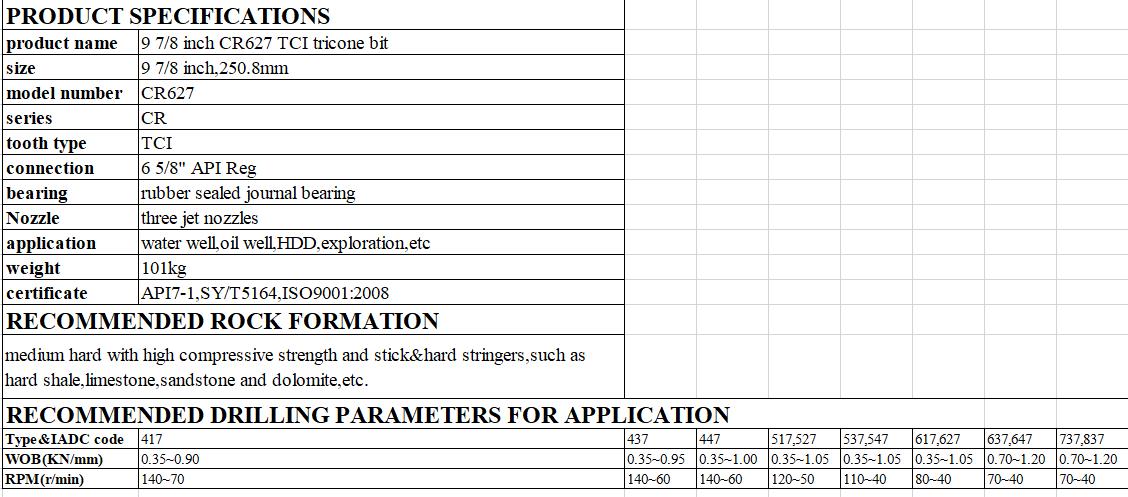

9 7/8Inch IADC627:

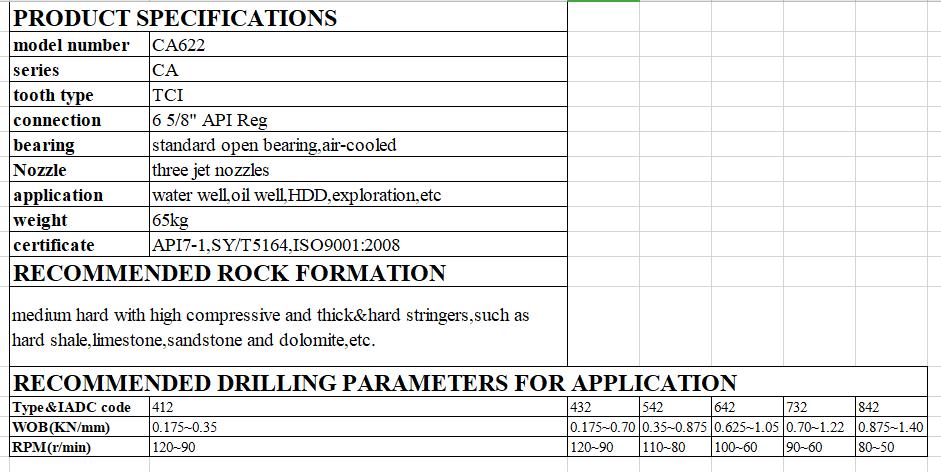

9 7/8Inch IADC622:

10Inch IADC625: