- Gaea

- 中国

- 5-25天

All of our tails are made of high-quality steel and then processed by cnc and carburized to ensure that they have excellent toughness and sufficient strength to meet the stringent requirements. Operating environment. In addition, according to the requirements, all the solder tails can be processed into male or female threads

T38 Shank Adapter Fukukawa

Related reports:

Introduction to the heat treatment process of heavy drilling tools;

Introducing Fukukawa T38 Shank Adapter for Mining Operations:

We are pleased to introduce the Fukukawa T38 shank adapter, a high-quality product specifically designed for mining operations. As a leading provider in the industry, we prioritize the use of premium alloy steel as the raw material for our shank adapters, ensuring superior performance and durability in demanding environments.

The Fukukawa T38 shank adapter features a T38 thread, which is a widely recognized standard in the industry. This thread type ensures a secure and reliable connection between the shank adapter and the drilling equipment, allowing for efficient power transmission during rock drilling operations. Our shank adapter is carefully manufactured using state-of-the-art CNC machining equipment and processes, guaranteeing exceptional quality in the details of the tail, internal water holes, and side flushing holes.

To further enhance the quality of our product, we implement advanced heat treatment and carburizing processes. The shank adapter undergoes a uniform heat treatment process, followed by precise straightening using sophisticated instruments. This ensures that the shank adapter maintains a straight and robust structure, capable of withstanding the impact and torque exerted by rock drilling machines. Additionally, the proper hardness of the shank adapter is crucial for achieving optimal drilling speed and prolonging the lifespan of both the drilling machine and the drill rods. We carefully control the hardness of our shank adapter to ensure its effectiveness, typically aiming for a quenching hardness ranging from HRC 38 to 45.

The Fukukawa T38 shank adapter plays a critical role in bearing the impact energy and torque of the drilling machine. Its specifications and hardness have a significant influence on drilling speed and the overall lifespan of the drilling equipment. Therefore, our shank adapter is meticulously crafted to meet these requirements. It features an appropriate length, smooth and flat end faces, perpendicular cross-sections to the axis, and a tight fit with the drilling machine's drill sleeve (with a clearance no greater than 0.5mm). These meticulous design considerations guarantee optimal performance and longevity.

In summary, the Fukukawa T38 shank adapter offered by our company is a premium product designed for mining operations. Its high-quality alloy steel construction, combined with advanced heat treatment and carburizing processes, ensures exceptional durability, strength, and reliability. With its T38 thread, precise machining, and adherence to strict quality control standards, our shank adapter provides efficient power transmission and contributes to the overall productivity and success of mining operations. Choose the Fukukawa T38 shank adapter for reliable and efficient rock drilling in the mining industry.

Gaea produce supporting tails for most rock drills currently on the market. All of our tails are made of high-quality steel and then processed by cnc and carburized to ensure that they have excellent toughness and sufficient strength to meet the stringent requirements. Operating environment. In addition, according to the requirements, all the solder tails can be processed into male or female threads.

Male threads are generally suitable for sedimentary rock, tunneling and other extended applications. When drilling space and total feed length are limited and important, female threaded shanks are used, such as underground ceiling anchoring.

The main role of the bit is to transfer torque, propulsion, impact and flushing medium to the drill pipe and bit.

Our brazing tails are designed to withstand the high impact of modern rock drills. They are made of special steel materials and have undergone carburization to increase the surface hardness. Now we can provide about 300 different specifications of brazing tails to match Tras, Tom Rock, Sandvik, Furukawa, Montebello, Denver and other series of rock drills. We produce supporting tails for most rock drills currently on the market. All of our tails are made of high-quality steel and then processed by cnc and carburized to ensure that they have excellent toughness and sufficient strength to meet the stringent requirements. Operating environment. In addition, according to the requirements, all the solder tails can be processed into male or female threads. Male threads are generally suitable for sedimentary rock, tunneling and other extended applications. When drilling space and total feed length are limited and important, female threaded shanks are used, such as underground ceiling anchoring. The main role of the bit is to transfer torque, propulsion, impact and flushing medium to the drill pipe and bit. Our brazing tails are designed to withstand the high impact of modern rock drills. They are made of special steel materials and have undergone carburization to increase the surface hardness. Now we can provide about 300 different specifications of brazing tails to match Tras, Tom Rock, Sandvik, Furukawa, Montebello, Denver and other series of rock drills.

Code No.: HD210/HD609/HD709/PD200

Thread Type: T38

Length: 410/690/620/380mm

Rock Drill Manufacturer: FUKUKAWA

HD210-T38-410

HD609-T38-690

HD709-T38-620

PD200-T38-380

Shank Adapter Packaging:

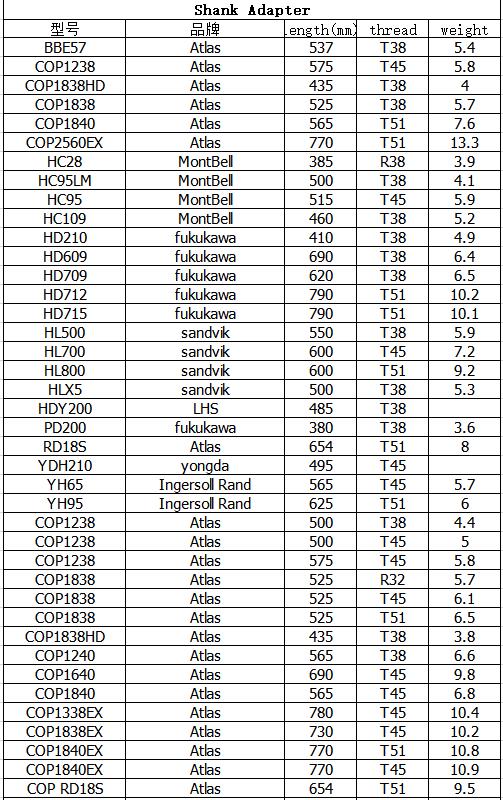

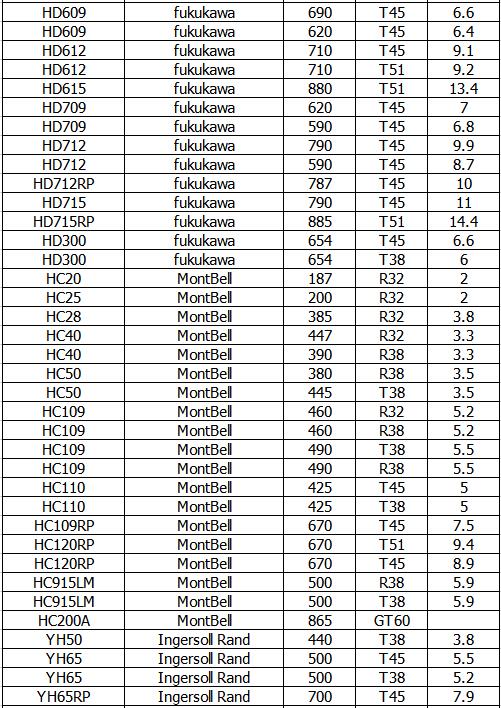

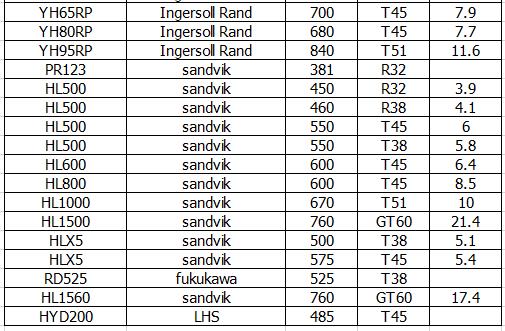

Specification: