- Gaea

- 中国

- 5-25天

- 30sets/month

The water-air slagging mechanism relies on the external injection joint to flush the water or gas through the drill tail, drill pipe,drill bit's inner hole or blow air to discharge the impact broken gravel to the hole and assist the impact broken roc

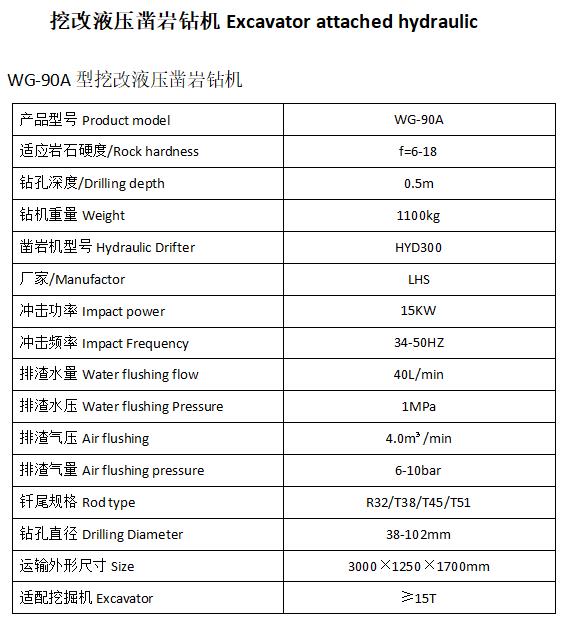

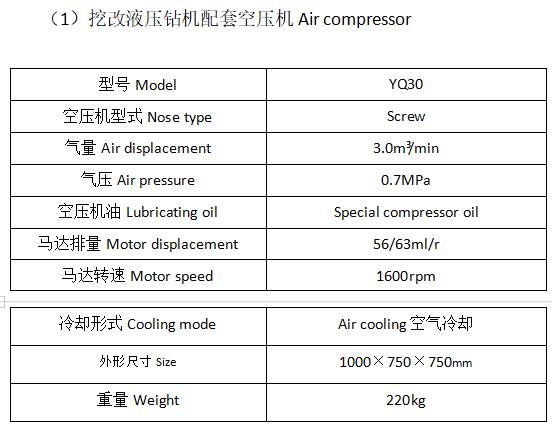

Excavator Drill Rigs WG90

Related reports:

Do you know what are the classifications of engineering drilling rigs;

The WG-90 Rock Drilling Rig and Excavator. This cutting-edge machine combines the functionalities of a rock drilling rig and an excavator, delivering outstanding performance and versatility in a wide range of applications.

The WG-90 is a powerful and reliable machine specifically designed to meet the demanding requirements of rock drilling and excavation projects. This innovative equipment incorporates advanced technologies and features, making it an ideal solution for your drilling and excavation needs.

Key Features of WG-90 Rock Drilling Rig and Excavator:

Unparalleled Rock Drilling Capability: The WG-90 boasts exceptional rock drilling capabilities, enabling it to penetrate even the most challenging rock formations with precision and efficiency. Equipped with a high-performance rock drilling system, this machine ensures optimal productivity and reliable operation in various geological conditions.

Versatility in Excavation Functions: With its dual functionality as an excavator, the WG-90 offers unparalleled versatility in handling different materials, including rocks, soil, and debris. The machine's advanced hydraulic system and substantial bucket capacity allow for efficient excavation, loading, and transportation, maximizing productivity on your job site.

Precision Control and Performance: The WG-90 is designed to provide precise control over drilling and excavation operations. Its user-friendly interface and ergonomic controls allow operators to easily adjust parameters and settings, ensuring accurate and efficient performance throughout the project.

Durability and Reliability: At Liaoning Gaea, we prioritize durability and reliability. The WG-90 is built with high-quality materials and components, ensuring robustness and longevity, even in the harshest working conditions. This machine is engineered to withstand rugged environments and prolonged operation, minimizing downtime and maximizing productivity.

Safety and Operator Comfort: Safety and operator comfort are paramount in the design of the WG-90. It is equipped with essential safety features, such as emergency stop buttons, protective guards, and advanced monitoring systems, ensuring a safe working environment. The operator's cabin provides a comfortable and ergonomic workspace, reducing operator fatigue and increasing overall efficiency.

The WG-90 Rock Drilling Rig and Excavator offer exceptional versatility and performance, enabling you to streamline your drilling and excavation operations effectively. Whether you are working on mining projects, construction sites, or infrastructure development, the WG-90 is the perfect choice to enhance productivity and achieve remarkable results.

At Liaoning Gaea, we take pride in delivering reliable and innovative machinery to our esteemed clients worldwide. Our team of experienced professionals is dedicated to providing exceptional customer service, technical support, and comprehensive after-sales assistance, ensuring your utmost satisfaction.

To learn more about the WG-90 Rock Drilling Rig and Excavator or to request a quotation, please do not hesitate to contact us. Our team is available to address any inquiries you may have and provide further information on product specifications, pricing, and delivery options.

Thank you for considering Liaoning Gaea as your trusted partner for your rock drilling and excavation needs. We look forward to the opportunity to serve you and contribute to the success of your projects.

Gaea Rock Drill rig Features

1. Strong versatility: can be assembled on any brand hydraulic excavator;

2. Maneuverable and flexible: 360-degree flexible in all directions;

3. High rate of return: fast working efficiency, low fuel consumption, saving labor and energy costs;

4. High cost performance: rock drilling excavator = drilling rig + excavator;

5. High safety: low risk of accidents and less health threats to workers;

6. Fine computer control: intelligent control, simple operation.

Truck mounted drill rig:

Working Principle of Hydraulic Rock Drill:

The piston is forced to reciprocate at high speed in the cylinder block by differential pressure action,

and the impact bit tail realizes the chisel effect.

The piston and the reversing valve move independently and restrict each other.

Before the piston cavity subjected to normal pressure oil,

the movement of the piston is through the change of directional control valve has been change after the piston chamber pressure and implementation;

The reversing valve is through the piston movement back and forth to open or close the oil signal hole,in order to change the pressure area of the reversing valve to achieve.

The hydraulic motor provides torque and speed to the bit tail through gear transmission.

When the bit touches the rock, the piston reciprocates to transfer the impact energy to the bit to break the rock through the bit tailand drill pipe.

The rotary motion of the hydraulic motor delivers the torque and rotation speed to the bit through the gearbox,

the bit tail and the drill pipe to assist the bit in crushing the rock.

The water-air slagging mechanism relies on the external injection joint to flush the water or gas through the drill tail, drill pipe,drill bit's inner hole or blow air to discharge the impact broken gravel to the hole and assist the impact broken rock.

FAQ:

1.Can a rock drilling rig handle different types of rock formations?

Yes, rock drilling rigs are designed to handle various rock formations, including hard rocks, sedimentary rocks, and fractured rocks, with different drilling techniques and tooling options.

2.How can I ensure the safety of using a rock drilling rig?

Safety measures such as proper training, wearing personal protective equipment (PPE), regular maintenance, and following manufacturer guidelines are essential for safe operation of rock drilling rigs.

3.What maintenance is required for a rock drilling rig?

Routine maintenance tasks include checking and replacing worn-out parts, lubricating components, inspecting hydraulic systems, and monitoring overall rig performance to ensure optimal functionality.