The core secret of drilling operation: DTH hammer and drill bit strategy

In drilling operation, the correct selection and use of DTH hammer, drill bit and other equipment are crucial, which is directly related to drilling efficiency, cost and engineering quality.

I. DTH hammer

1. Size and aperture association:

The size of DTH hammer is mainly determined by the borehole diameter and rock type. For blasting holes, the borehole diameter of DTH drilling is generally between 89mm and 252mm. Boreholes with diameters less than 89mm are usually drilled by top hammer, while those with diameters greater than 252mm are mostly drilled by rotary. It is worth noting that the minimum aperture diameter applicable to the DTH hammer is its nominal size. For example, the minimum applicable aperture diameter of a 4-inch hammer is 4 inches. In this case, sufficient annular space will be formed between the hammer and the hole wall, and between the drill pipe and the hole wall, which is crucial for slag removal.

2. Matching with drill bit:

The maximum size of the matching drill bit is the hammer size plus 1 inch. For example, the maximum drill bit size that matches a 4-inch hammer is 5 inches.

3. Key points for selecting drill pipes:

The closer the outer diameter of the drill pipe is to the outer diameter of the DTH hammer, the better the slag removal effect, and the risk of drill jamming can be reduced. From the processing technology point of view, the surface finish and dimensional accuracy of cold-drawn tubes are better than those of hot-rolled tubes. The smooth surface can prevent the steel pipe from peeling and reduce the impact of metal debris on the service life of the DTH hammer. In addition, if the thread and the main body of the drill pipe are connected by friction welding, the strength of the drill pipe can be enhanced; if the thread part is well heat treated, the reliability and strength of the thread can be improved, making the operation of the connecting rod smoother, thereby improving work efficiency and overall drilling speed.

2. Down-the-hole drill bit

1. Manufacturing process

The drill bit body is usually made of cemented carbide by machining, followed by heat treatment to achieve the specified hardness, ensure that the surface compressive stress has sufficient fatigue resistance, and finally embed cemented carbide drill teeth.

2. Drill bit types and applicable scenarios

● Convex sharp-tooth drill bit: This design can achieve the fastest perforation efficiency and is most suitable for medium-soft rock with low abrasiveness.

● Flat drill bit: For hard rock with high abrasiveness, flat drill bit can effectively increase the service life of the drill bit. When the outer edge of the ball tooth is large, the drill bit can be further sharpened to extend its service life and reduce the cost of use.

● Concave ball tooth drill bit: It is also suitable for hard rock with high abrasiveness. It is more suitable for medium-hard rock with developed joints and many cracks, which can effectively reduce the probability of hole deviation.

III. Actual application scenarios

1. Open-pit mines and quarries: Since these places are usually long-term operations, durable down-the-hole hammer are required. Some down-the-hole hammer with excellent performance can be repaired and used multiple times by changing the direction of the hammer outer tube before being completely replaced.

2. Drilling of building materials: In holes with a diameter greater than 89mm, the straightness of the down-the-hole drilling is usually better than that of the top hammer drilling, which is very critical for drilling of building stones (such as marble, etc.), because this type of drilling requires high straightness.

3. Exploration drilling: The working environment of exploration drilling is often remote and the related facilities are poor, so the down-the-hole hammer is required to be simple in design, highly reliable, and able to adapt to high wind pressure drilling.

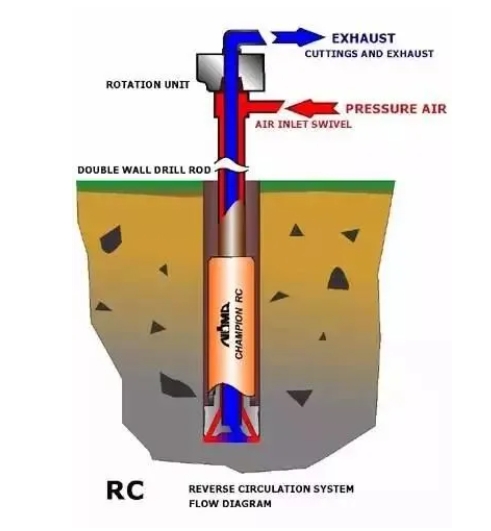

4. Reverse circulation impact drilling: This drilling method is cheaper than diamond coring drilling. The process used is the same as that of ordinary down-the-hole hammers, but a reverse circulation drill pipe is used. High-pressure air is blown in through the gap between the inner and outer walls of the drill pipe, so that the drill cuttings are discharged from the inner wall of the drill pipe, and then the drill cuttings are collected with a dust bag.

5. The importance of the drill operator: In actual use, the drill operator is an important factor that cannot be ignored. An experienced drill operator can effectively adjust the drilling parameters to reduce the probability of hammer failure and extend the service life of the hammer.

6. DTH hammer value assessment: There are many types of DTH hammer on the market with different prices. The value of an DTH hammer cannot be measured by focusing only on its materials and design. What is more important is to comprehensively consider the balance between the efficiency it brings to users and the cost of drilling. For example, although an DTH hammer is cheap and durable, if it has high fuel consumption and leads to excessively high drilling costs, then it is not an ideal choice; on the contrary, if an DTH hammer is expensive but can bring high efficiency and low drilling costs, then it is a high-quality DTH hammer. In addition, it is also crucial whether the DTH hammer manufacturer can provide sufficient technical support and usage guidance, which can effectively help users improve drilling efficiency and reduce usage costs.