Liquid Oxygen Rock Blasting System Compared with Traditional Explosive

New technology: O2 rock demolition system

Link:

Understanding Traditional Explosives in Quarrying

The Role of Traditional Explosives

Traditional explosives have been the cornerstone of rock blasting in quarries for decades. Their primary function is to deliver a powerful and immediate release of energy to fracture large rock masses, facilitating easier extraction and transportation. The key advantages of using traditional explosives include:

High Energy Output: Traditional explosives provide a substantial amount of energy in a short span, effectively breaking even the toughest rock formations.

Speed and Efficiency: The rapid energy release ensures quick fragmentation, significantly boosting productivity.

Cost-Effectiveness: Compared to newer technologies, traditional explosives are generally less expensive, making them a cost-effective choice for large-scale operations.

Drawbacks of Traditional Explosives

Despite their widespread use and effectiveness, traditional explosives come with several notable disadvantages:

Flyrock: The unintended projection of rock fragments beyond the blast site poses significant safety hazards to workers and nearby structures.

Large Shock Waves: Powerful shock waves can cause ground vibrations, leading to structural damage in surrounding areas and disturbing local communities.

Harmful Gas Emissions: Explosive reactions release toxic gases, contributing to environmental pollution and health risks.

Uncontrollability: The unpredictable nature of explosions makes it difficult to control the extent and precision of rock fragmentation.

Regulatory Restrictions: Due to safety and environmental concerns, obtaining permits for explosive use is increasingly challenging in many countries.

Introducing the Liquid Oxygen Rock Blasting System

What is the Liquid Oxygen Rock Blasting System?

The Liquid Oxygen Rock Blasting System is an advanced technology designed to revolutionize rock blasting processes in quarrying. Unlike traditional explosives that rely on chemical reactions to release energy, this system utilizes liquid oxygen (O₂) to generate the necessary energy for rock fragmentation. By harnessing the properties of liquid oxygen, the system ensures a controlled and efficient rock-breaking process with minimal environmental and safety risks.

How Does It Work?

The Liquid Oxygen Rock Blasting System operates by injecting liquid oxygen into specially designed rock splitting tubes embedded in drilled holes within the rock mass. The controlled release and rapid expansion of liquid oxygen create sufficient force to fracture the rock without the unpredictable and violent reactions associated with traditional explosives.

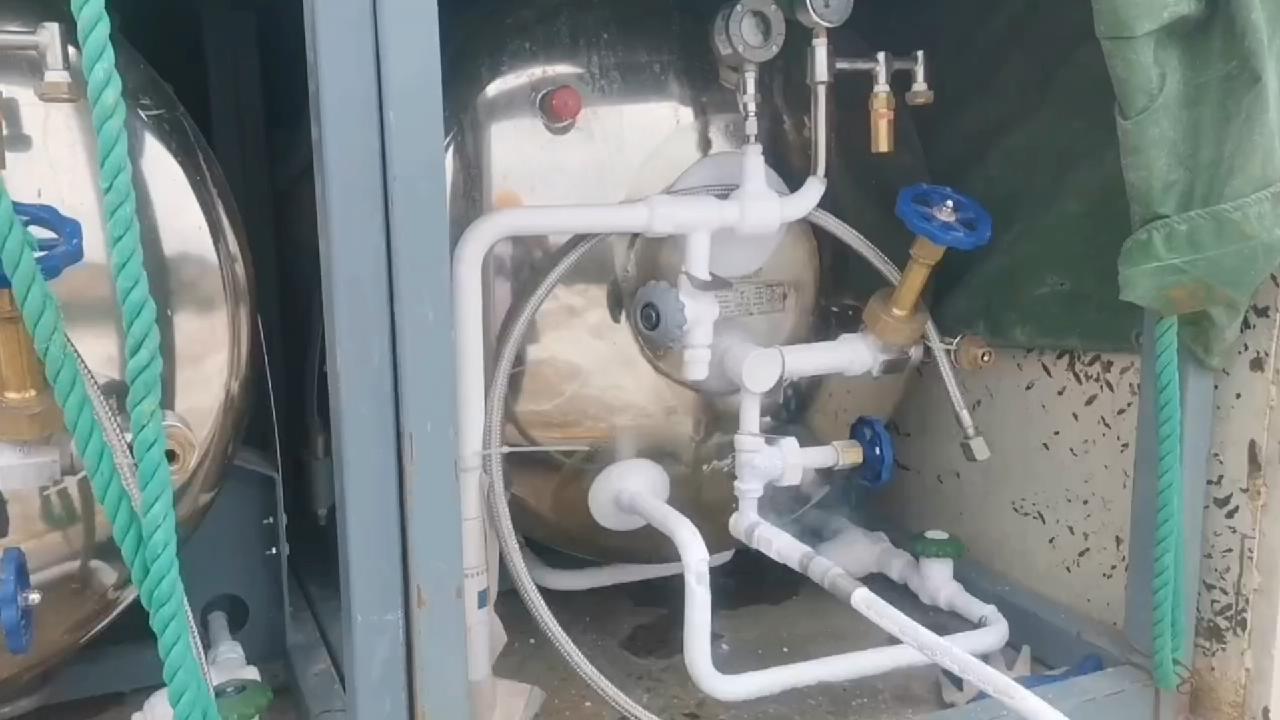

(Figure 1 shows the process of gas filling tank filling liquid oxygen into the diverter)

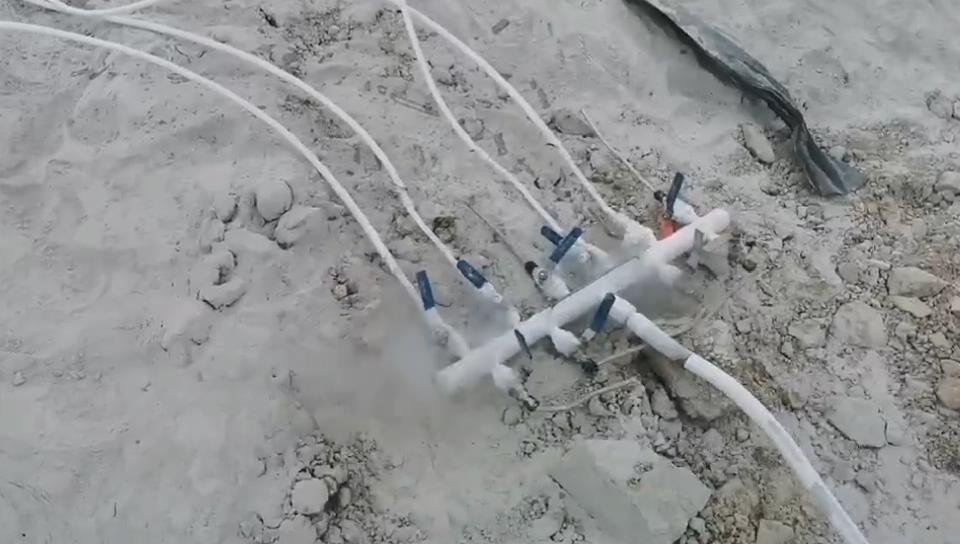

(Figure 2 shows the process of the splitter filling liquid oxygen into the rock splitting tube.)

(Figure 3 shows the working effect of the O2 rock blasting system.)

Comparative Analysis: Liquid Oxygen Rock Blasting System vs. Traditional Explosives

Safety Enhancements

One of the most compelling advantages of the Liquid Oxygen Rock Blasting System is its enhanced safety profile:

Controlled Energy Release: Unlike traditional explosives, which release energy instantaneously and unpredictably, the liquid oxygen system allows for precise control over energy release. This minimizes the risk of flyrock and excessive shock waves, ensuring a safer environment for workers and nearby communities.

Reduced Harmful Emissions: The primary byproducts of the liquid oxygen system are water and carbon dioxide, significantly reducing the emission of toxic gases compared to traditional explosives. This contributes to a cleaner and healthier work environment.

Lower Risk of Accidental Detonations: The absence of sensitive explosive materials decreases the likelihood of accidental detonations, further enhancing operational safety.

(Placing a gas filling tank not far from the rock blasting still does not affect the rock blasting process, proving that the shock wave is smaller)

Environmental Impact

The Liquid Oxygen Rock Blasting System offers a more environmentally sustainable approach to rock breaking:

Minimal Environmental Footprint: With fewer harmful emissions and reduced ground vibrations, the liquid oxygen system lessens the environmental impact of blasting operations.

Water-Friendly Operations: The system can be effectively used in water-filled cavities without causing water contamination, unlike traditional explosives which can lead to hazardous runoff.

Operational Control and Precision

Precision is crucial in quarrying to ensure optimal rock fragmentation and minimize waste:

Uniform Fragmentation: The controlled energy release results in uniformly sized rock fragments, enhancing the efficiency of material handling and processing.

Reduced Overbreak: Precise energy application minimizes overbreak, conserving valuable rock material and reducing operational costs.

Enhanced Predictability: The ability to predict and control the extent of rock fragmentation allows for better planning and resource allocation.

Cost Considerations

While the Liquid Oxygen Rock Blasting System offers numerous advantages, it is essential to consider the cost implications:

Higher Initial Investment: The system is generally more expensive than traditional explosives due to the cost of liquid oxygen and specialized equipment. However, this initial expense can be offset by long-term savings.

Long-Term Savings: Enhanced safety, reduced environmental impact, and improved efficiency can lead to long-term cost savings by minimizing accidents, regulatory fines, and material waste.

Regulatory Compliance and Ease of Transport

Navigating the regulatory landscape is a significant challenge for traditional explosives:

Simplified Permitting: Liquid oxygen systems face fewer regulatory hurdles compared to traditional explosives, facilitating smoother project approvals.

Safe Transportation: Classified as conventional cargo, liquid oxygen systems are easier and safer to transport via sea freight, avoiding the stringent regulations associated with explosive materials.

Market Recognition and Adoption

Despite its advantages, the Liquid Oxygen Rock Blasting System faces challenges in terms of market recognition:

Limited Global Awareness: Compared to traditional explosives, the O₂ system is relatively new and not widely recognized globally. Building awareness and trust in its effectiveness is crucial for broader adoption.

Higher Cost: The higher cost of the O₂ system compared to some low-quality traditional explosives can be a barrier for adoption, especially in regions where budget constraints are significant.

Addressing Traditional Explosive Pain Points

Flyrock Mitigation

Flyrock is a major safety concern with traditional explosives, often resulting in injuries and property damage. The Liquid Oxygen Rock Blasting System's controlled energy release significantly reduces the occurrence of flyrock, enhancing overall site safety.

Shock Wave Reduction

Large shock waves from traditional explosives can cause structural damage and disturb local communities. The O₂ system's ability to manage and minimize shock wave emissions ensures that blasting operations have a reduced impact on the surrounding environment.

Harmful Gas Emissions

Traditional explosives release toxic gases that pose health risks and environmental challenges. The Liquid Oxygen Rock Blasting System primarily produces water and carbon dioxide, eliminating the harmful gas emissions associated with traditional blasting methods.

Enhanced Controllability

The unpredictability of traditional explosives makes it difficult to control the extent of rock fragmentation. The O₂ system offers precise control over energy release, allowing for predictable and uniform rock breaking, which is essential for efficient quarrying operations.

Conclusion

The Liquid Oxygen Rock Blasting System stands as a transformative technology in the quarrying industry, addressing many of the safety and environmental challenges posed by traditional explosives. While the initial costs may be higher, the long-term benefits of enhanced safety, environmental sustainability, and operational efficiency make it a compelling alternative for modern quarrying operations.

As the demand for sustainable and safe rock-breaking methods continues to grow, the Liquid Oxygen Rock Blasting System is well-positioned to become a preferred solution in the industry. By mitigating the inherent risks of traditional explosives and offering superior control and precision, this innovative technology not only ensures compliance with stringent regulations but also contributes to the overall well-being of workers and the environment.

For quarry operators seeking to modernize their operations and prioritize safety and sustainability, the Liquid Oxygen Rock Blasting System offers an effective and forward-thinking solution.