CO2 rock blasting system and its advantages and disadvantages

New technology: O2 rock demolition system

Link:

CO2 rock blasting began in the 1950s and began to develop in the United States in the 1980s. It was mainly developed for coal mining faces in high-gas mines to avoid explosion accidents caused by flames generated by explosive blasting. In 2015, with the development of science and technology, domestic CO2 rock blasting equipment manufacturers gradually emerged (the main components are still imported, and the domestic failure rate is slightly higher), but its maturity is insufficient and it is still in a stage of continuous growth and development.

Although there have been technological breakthroughs in domestic CO2 rock blasting construction, there is still a long way to go, and there are still many technologies that need to be improved and upgraded. The blasting volume is far behind that of traditional explosive blasting. In the case of blasting failure, the operation is more complicated than that of hydraulic splitting equipment, and the interval between cycles is long.

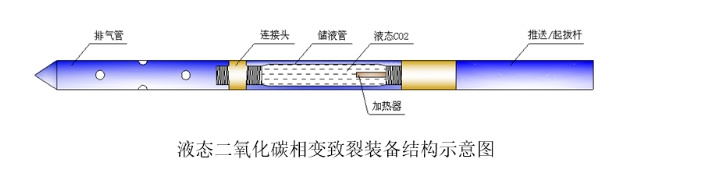

Liquid CO2 phase change fracturing is a physical fracturing process. Liquid CO2 is heated chemically to increase its pressure to 20MPa~60MPa. High-pressure liquid CO2 breaks through the constant pressure shear plate and quickly turns into gas. Its volume expands more than 600 times. The instantaneous release of gas expansion can cause the coal body around the borehole to fracture. The volume expansion process of liquid CO2 absorbs a large amount of heat, which can effectively reduce the temperature of the coal body within the fracturing range, which is conducive to inhibiting the spontaneous combustion of coal seams. Liquid CO2 phase change fracturing uses low-pressure start-up (9v), which is safer than traditional blasting, and does not require gun inspection. People can enter after blasting to achieve continuous work. The structure of liquid CO2 phase change fracturing equipment is shown in the figure below.

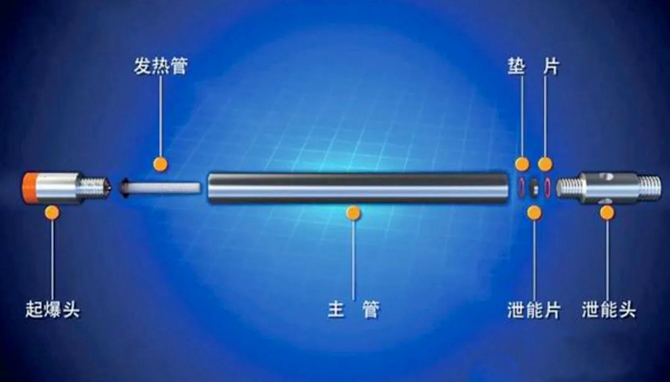

Principle of CO2 rock blasting: CO2 gas can be converted into liquid under a certain high pressure. The liquid CO2 is compressed into a cylindrical container (blasting tube) by a high-pressure pump, and the rupture disc, heat-conducting rod and sealing ring are loaded. The alloy cap is tightened to complete the preparations before blasting. The blasting tube, the safe cloud milli-difference initiator and the power cord are brought to the blasting site, the blasting tube is inserted into the drill hole and fixed, and the initiator power supply is connected. When the micro-current passes through the high-heat-conducting rod, high temperature is generated to break through the safety film, and the liquid CO2 is instantly gasified. The rapid expansion produces a high-pressure shock wave that causes the pressure relief valve to open automatically. The blasted objects or deposits are rapidly pushed outward by the geometric equivalent shock wave. The entire process from initiation to end only takes 0.4 milliseconds, and it operates at low temperature, does not merge with the liquid and gas in the surrounding environment, does not produce any harmful gases, does not produce arcs and electric sparks, and is not affected by high temperature, high heat, high humidity, and high cold. It has a dilution effect on gas during underground blasting, without shock and dust. CO2 is an inert gas and a non-flammable and explosive substance. The explosion process is a process of volume expansion, which is physical work rather than a chemical reaction.

Advantages of CO2 rock blasting:

1. It has inherent safety characteristics. It is very safe in terms of storage, transportation, carrying, use, and recycling. The main engine is separated from the blasting equipment, and the time from filling to the end of blasting is short. It only takes 1-3 minutes to fill liquid CO2, and only 4 milliseconds from detonation to the end. There is no dud during the implementation process, and no need to check the gun. The safety warning distance is short and there are no safety hazards. The blasting tube is easy to recover and can be used continuously.

2. It can be directional blasting and delayed control, especially in special environments such as residential areas, tunnels, subways, underground and other environments. There is no destructive vibration and short wave during the implementation process, and there is no destructive effect on the surrounding environment.

3. There is no need for a pyrotechnic warehouse, simple management, easy operation, few operators, and no need for professional personnel on duty.

4. Its performance is more prominent when used in mines, whether it is a high-gas mine, a rock burst mine, a mine with complex hydrogeological conditions, or a mine prone to spontaneous combustion.

5. The source of materials is rich and can be obtained locally. Liquid CO2 is available in chemical plants and gas filling stations. Improve efficacy, increase benefits and reduce costs. Reduce complicated approval and review procedures and management restrictions. Before the injection of CO2, all are non-explosive products.

6. In order to obtain a larger equivalent power, the blasting tubes can be used in parallel according to the on-site conditions.

7. Environmental protection: Directed energy release does not damage the surrounding environment, does not produce harmful gases such as carbon monoxide and nitrogen oxides, can better improve the working environment, and is beneficial to the health of workers

8. Convenience: Through different CO2 (CO2) filling amounts, replacing different types of fixed energy pressure relief plates and heating activators can control the working pressure of the expansion system, so as to adapt to different working environments.

9. Economic: The whole system can be used repeatedly and has low cost.

10. Safety: The assembly, filling and transportation processes are safe and reliable, and compared with explosive blasting, the dud cannon can completely eliminate accidents.

11. Fast: The assembly and filling operations are simple, and the blasting preparation time is short, which can greatly improve work efficiency and mass production.

Disadvantages of CO2 rock blasting:

1. Low efficiency: The steps are too complicated, and there are only a few explosions a day. The more links, the more chances of problems. Such as filling, wiring, sealing and other links.

2. Requirements for the air surface: It is effective only when the air surface is used. It is not suitable for deep foundation pits or working surfaces with poor air quality.

3. Low output: It is impossible to achieve multi-row blasting, which means that the number of blasting tubes in a single blasting should not exceed two rows. If it exceeds one row, it is easy to get stuck or blow up the blasting tube.

4. High cost: The activator used is a special, disposable item, and the blasting cost is high when the output is not high.

5. High requirements: The blasting tube filling process and on-site construction are both complicated, and the quality requirements for the blastholes are high.

6. Noise and safety: Although the blasting vibration force is not large, the sound is obvious after all. If it is to be used in residential buildings and buildings around, it should try to consult the local safety supervision and environmental protection department for permission.

7. It is difficult to control the direction of flying stones. Although there are relatively few flying stones, it is sometimes difficult to grasp the direction of flying stones.

8. Occasionally, cracked pipes may fly up.