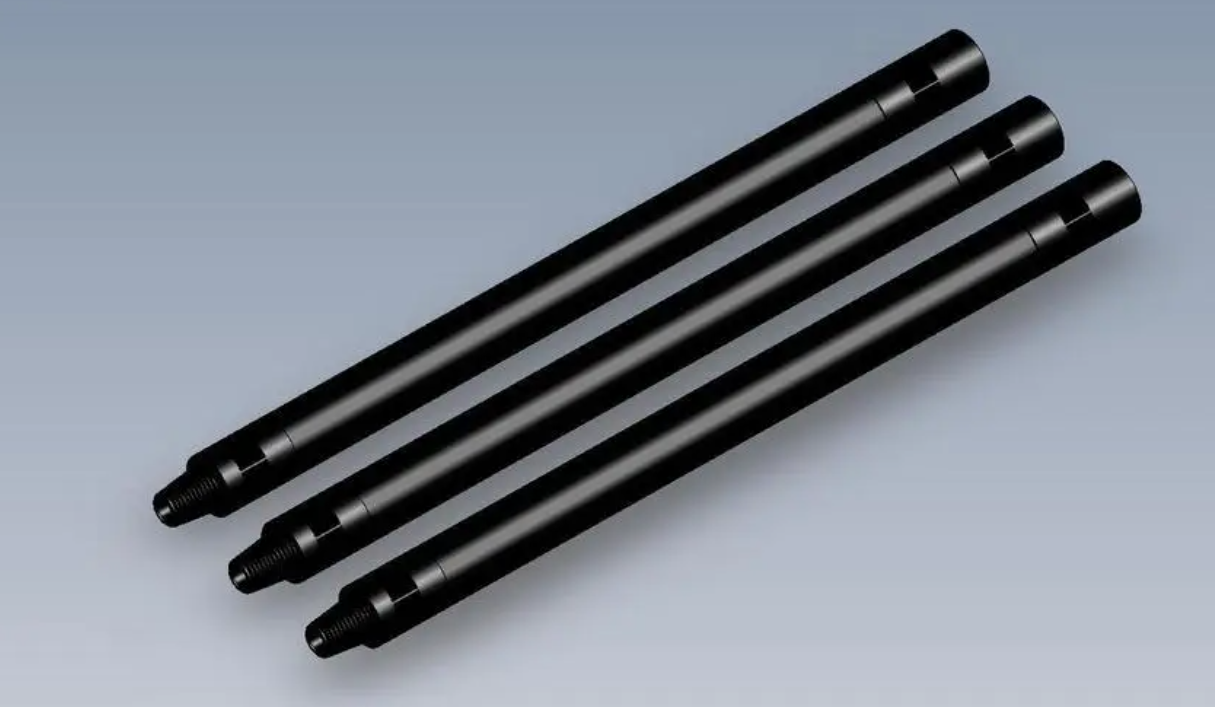

An article to extend the life of your drill pipe

Related products Link:

1. When using a new drill pipe, it should be ensured that the threaded thread of the front section of the drill bit (protecting the shaft head) is also close to the new one. A bad threaded rotor can easily damage the threaded thread of the new drill pipe, resulting in water leakage, snapping, and loosening. off state.

2. When using the drill pipe for the first drilling, you should first "grind the new buckle", which includes, first apply the thread oil, then use the drill to tighten it with all your strength, open the buckle, and apply the thread Open the oil again, and repeat this three times to avoid new wear and buckle.

3. Keep the drill pipe in a straight line between the ground and the ground as much as possible, so as to avoid the side force of the threaded part and cause unnecessary wear, or even skipping. It is very important to pay attention to anchoring the drilling rig to avoid force movement during construction of.

4. Slowly tighten the buckle to reduce overheating and wear.

5. Every time you buckle up, you must tighten it with full torque, and always pay attention to whether the clip is in good condition.

6. Shorten the distance from the drilling rig to the entrance, because if the drill pipe lacks support, it will easily bend and deform when the drill pipe is pushed forward, resulting in a shortened service life.

7. Keep the entrance angle as small as possible, and slowly change the angle according to the safety requirements of the drill pipe.

8. Do not exceed the maximum bending radius of the drill pipe, and pay special attention to the angle change when drilling into a horizontal section and when drilling out.

9. Keep using drill pipes in turn, avoid using fixed drill pipes for guiding and back expansion, and must take turns to avoid excessive wear and tear.